Method for producing a cooling body for an electronic component

A technology of electronic components and cooling bodies, which is applied in the direction of modification of power electronics, electrical components, and structural parts of electrical equipment, and can solve problems such as work and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

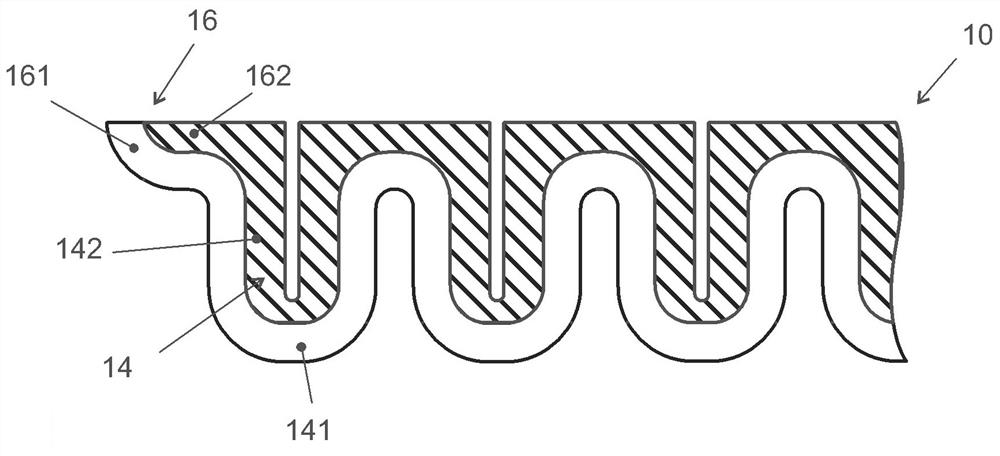

[0023] In the drawings the same reference signs denote the same or similar elements.

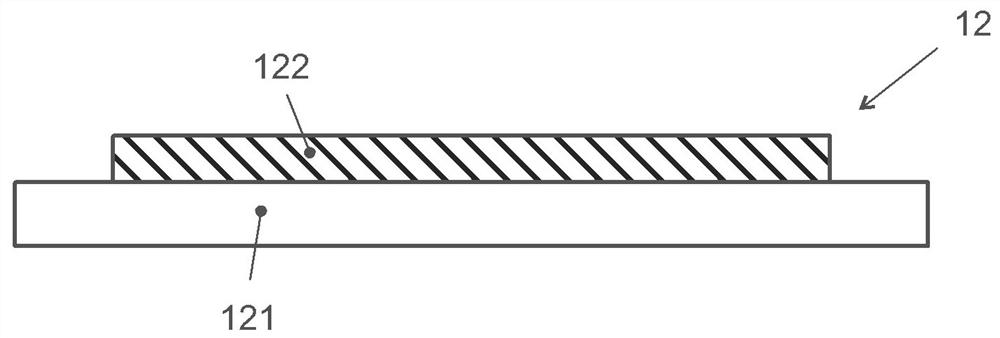

[0024] figure 1 The starting materials for carrying out the method according to the invention for producing the heat sink 10 are shown in a very schematic illustration. A sheet metal stack 12 consisting of aluminum sheet metal 121 and copper sheet metal 122 is used as raw material. In the embodiment shown, the two sheet metals 121 , 122 have similar material thicknesses, but the aluminum sheet metal 121 projects laterally beyond the copper sheet metal 122 on all sides. The sheets 121 , 122 are not brazed or welded to each other due to the incompatibility of aluminum and copper. Rather, mechanical stabilization is sufficient for their relative position. The mechanical stability can be improved by point-by-point bonding.

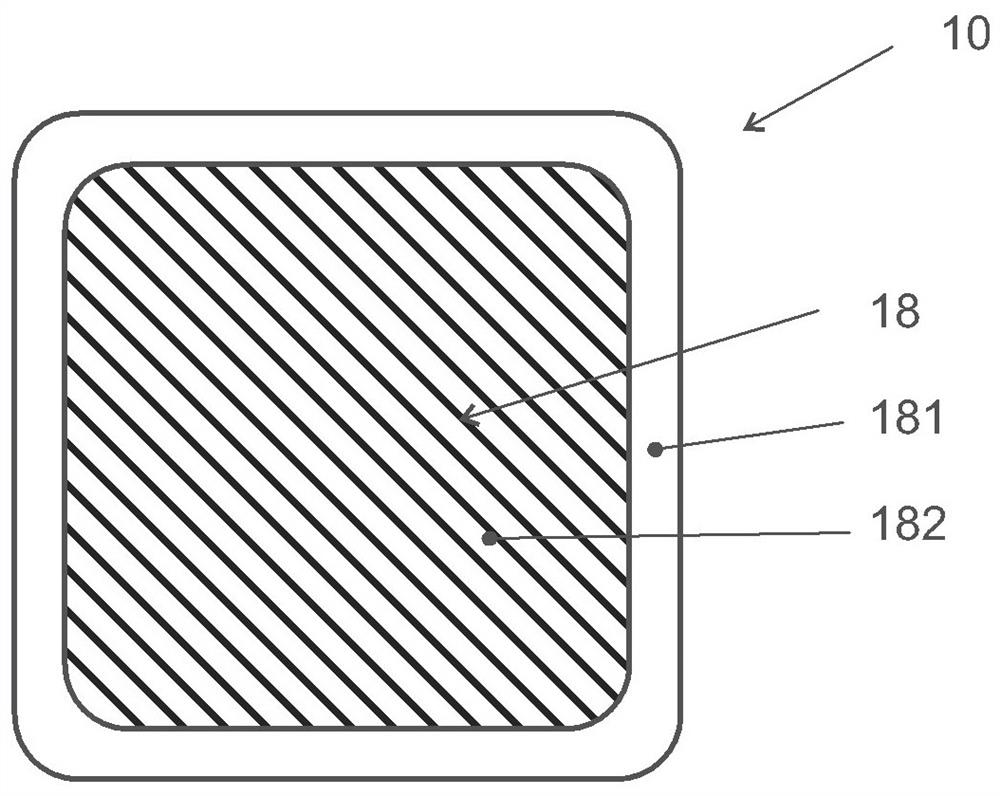

[0025] exist figure 1 The raw material shown in is subjected to the cold stamping method according to the invention and formed into a cooling body 10, wherein in figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com