Lifting flutter dust removal type gas-solid two-phase cyclone separator

A flow separation and gas-solid technology, which is applied in the field of gas-solid two-phase cyclone separators, can solve the problems of inability to clean dust, different particle sizes, and fire, and achieve the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing:

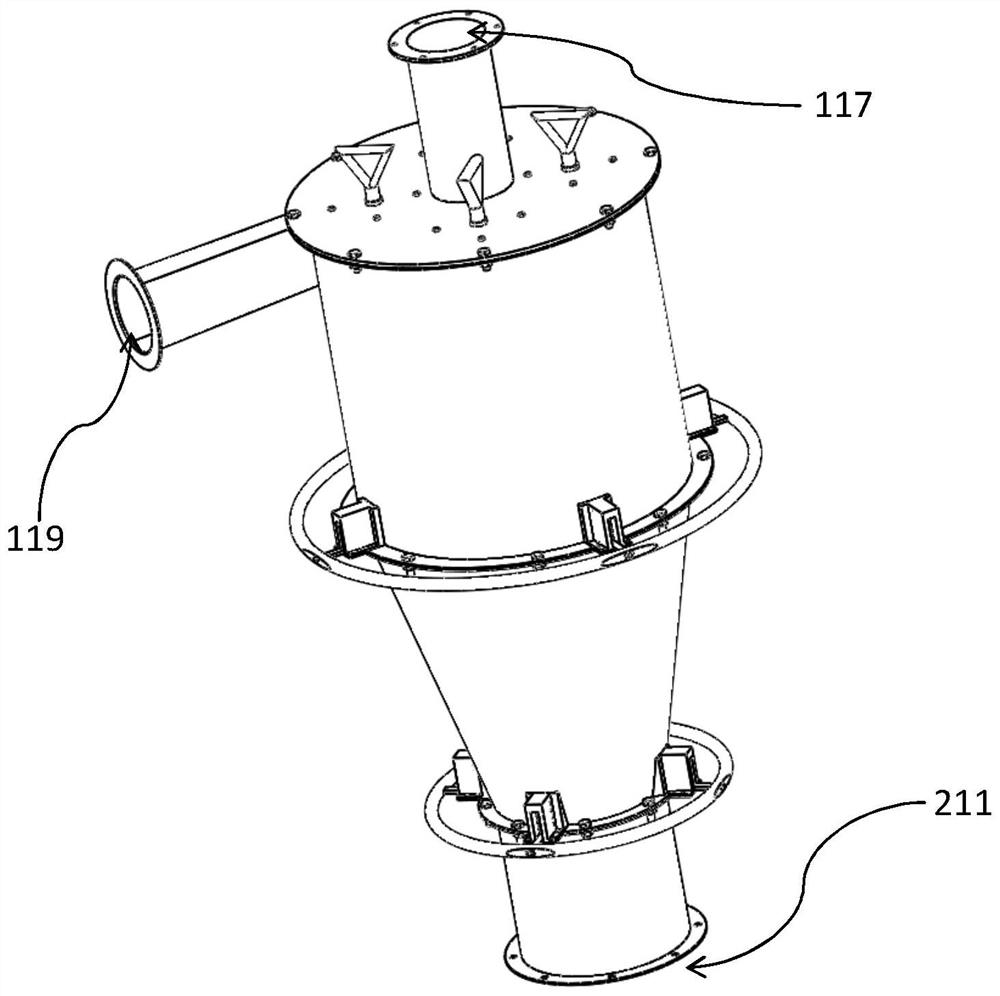

[0046] The overall appearance view of this cyclone separator is as follows: figure 1 As shown, the dust-containing gas enters the cyclone from the inlet port 119, and after being separated by the cyclone, the gas phase is discharged from the gas phase outlet 117, and the dust is discharged from the dust outlet 211.

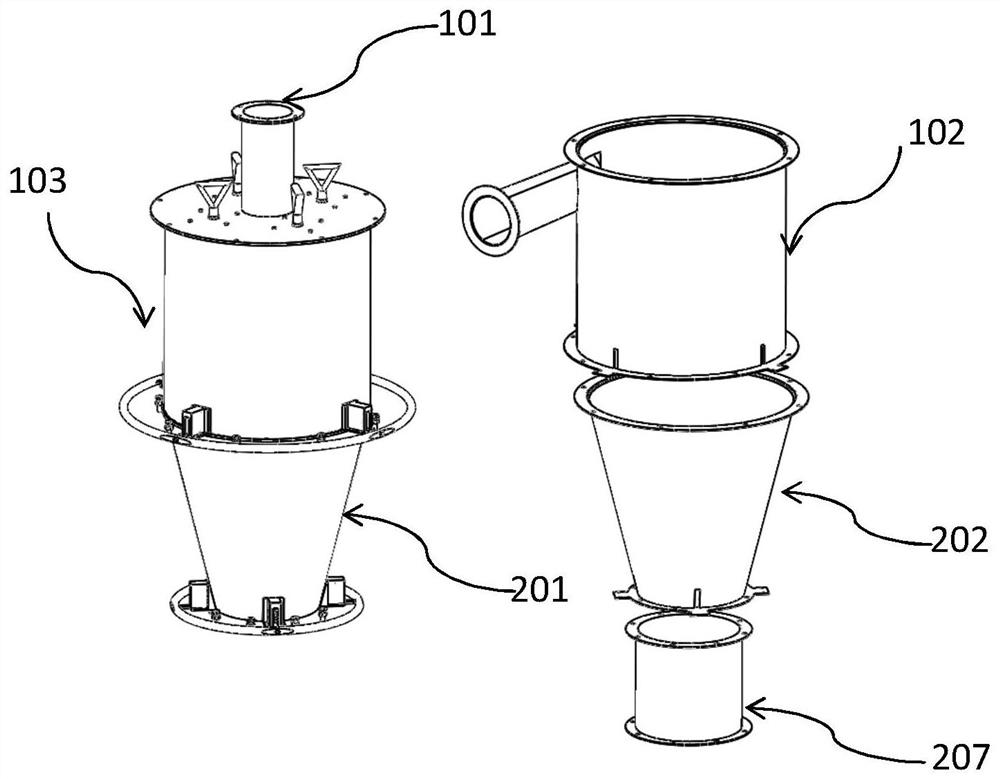

[0047] figure 2 It is an exploded view of the exterior of the dust removal device of the manual cyclone dust collector, which mainly consists of the gas phase outlet plate 101, the outer barrel wall 102 of the overflow ash filtering area, the inner lining layer 103 of the overflow ash filtering area, and the outer barrel wall of the cyclone ash filtering area 201. An inner liner 202 and a rectifying cylinder 207 are formed in the cyclone ash filter area.

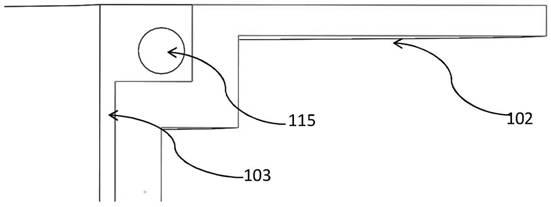

[0048] image 3 It is the overall cross-sectional view of the dust removal device of the manual cyclon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com