Electrostatic conveyor belt and impurity removing machine

A conveyor belt and electrostatic technology, applied in the field of transportation equipment, can solve the problems of difficulty in adapting to porous walls, high wall requirements, and difficulty in exerting advantages in thin air areas, etc., and achieve the effects of light weight, low noise, and strong wall adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

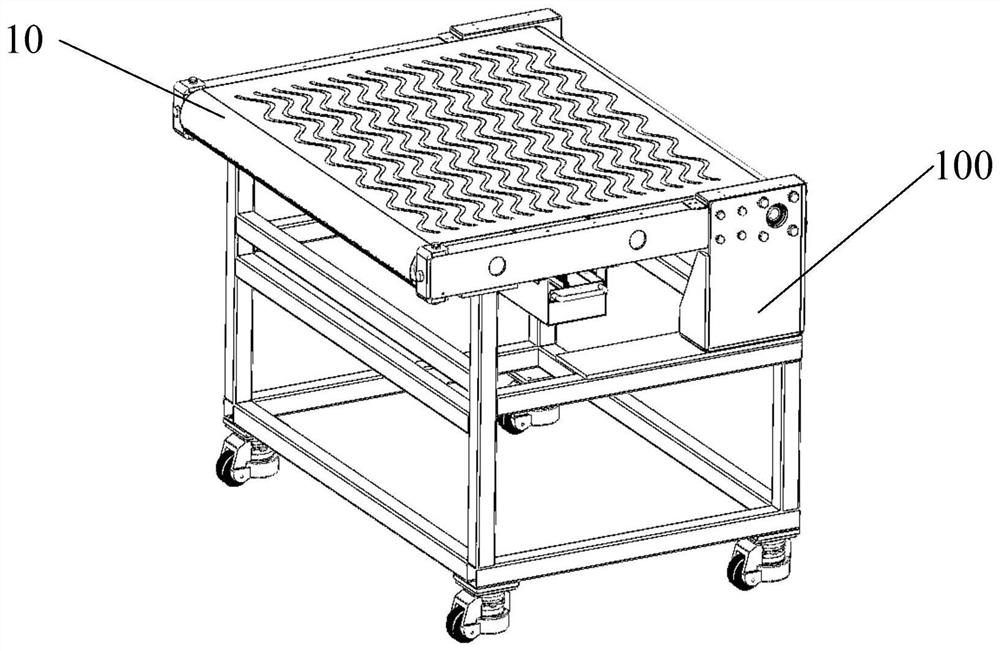

[0032] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Among them, the terms "first", "second" and so on are only used for descriptive purposes, and cannot be understood as indicating or implying relative importance or implicitly specifying the number of indicated technical features. Therefore, "first" is limited to , "second", etc. may expressly or implicitly include one or more of these features. In the description of the present invention, unless otherwise specified, "plurality" means two or more.

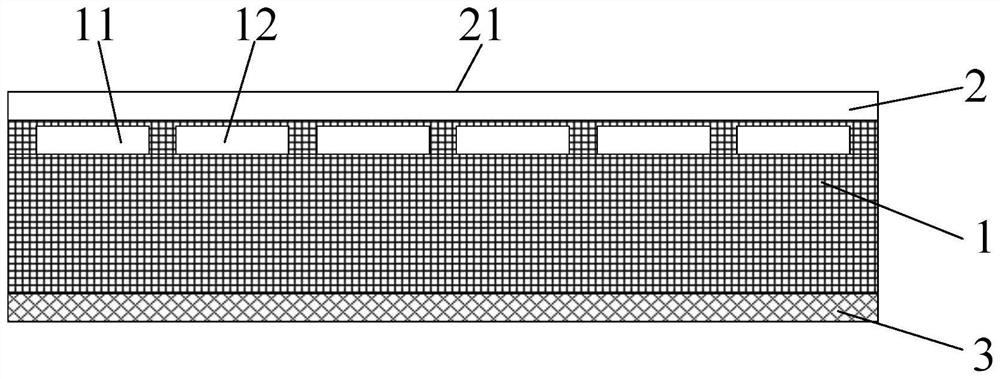

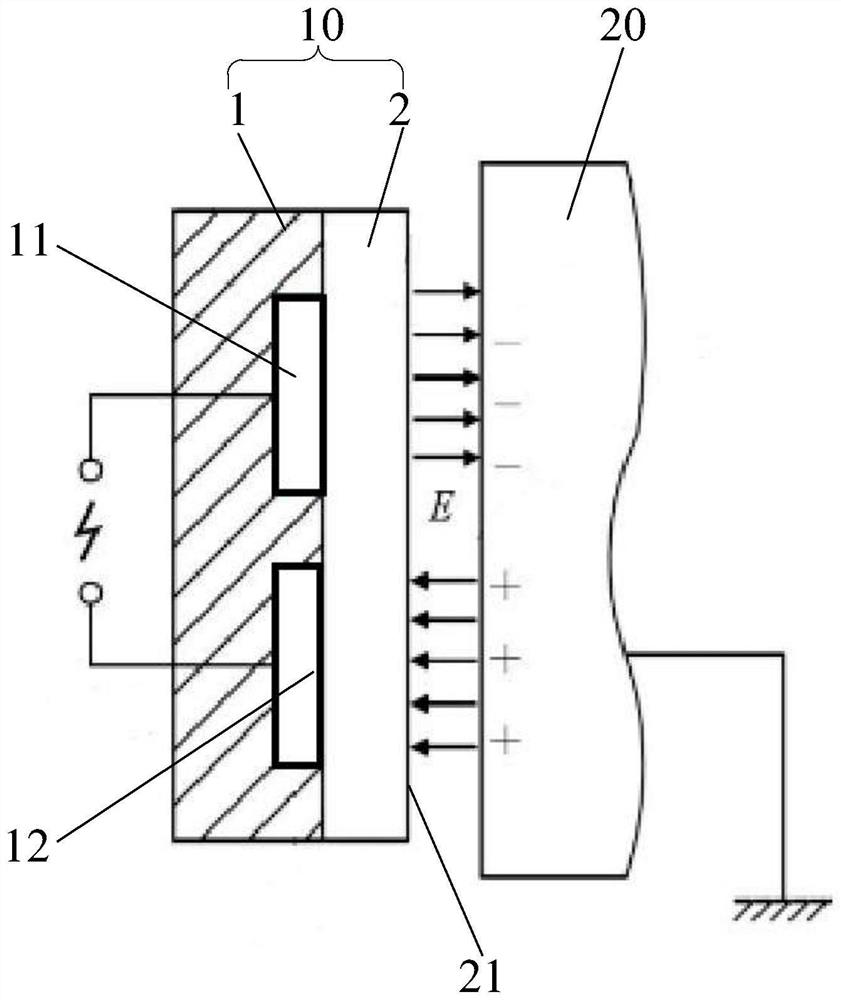

[0033] Such as figure 1 As shown, the present invention provides an electrostatic conveyor belt 10, which includes an insulating base layer 1 and an insulating adsorption layer 2, wherein:

[0034] The insulating base layer 1 has a first surface and a second surface oppositely arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com