A Push Type Expanding Set Finishing Fixture

A technology of expanding sleeves and fixtures, which is applied in the direction of expanding the mandrel, etc., can solve the problem that the end face positioning fixture of the gear inner cavity cannot be installed, and achieve the effects of saving process steps, improving machining accuracy, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

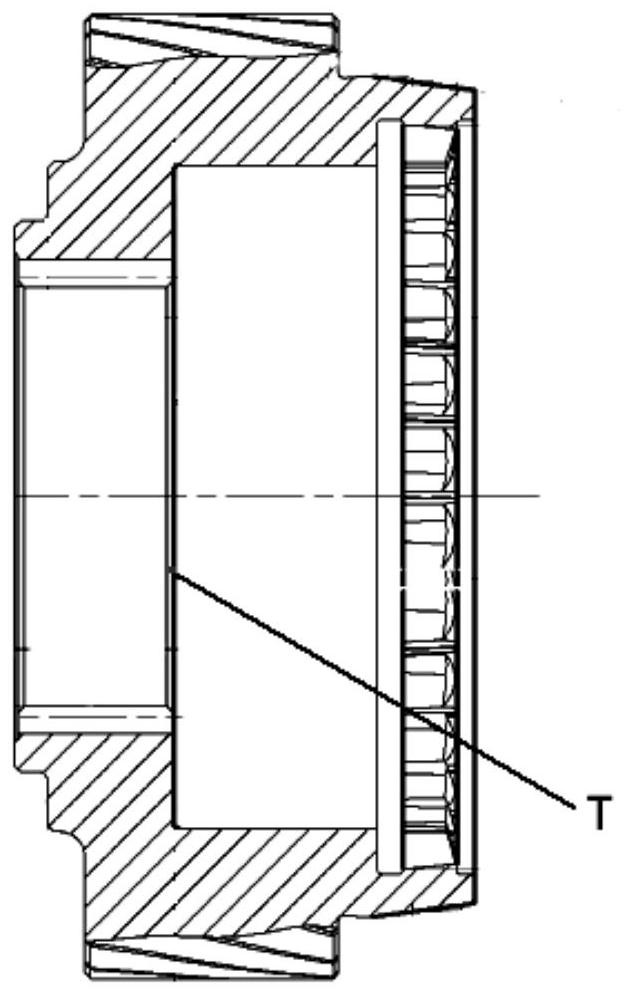

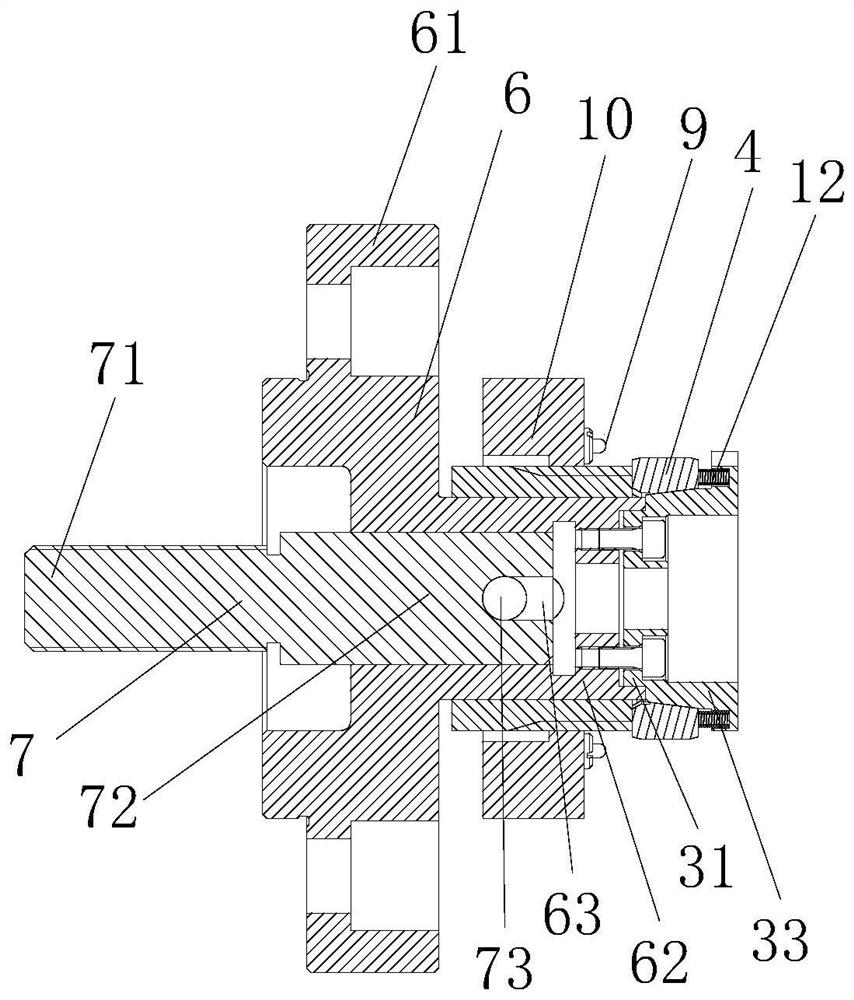

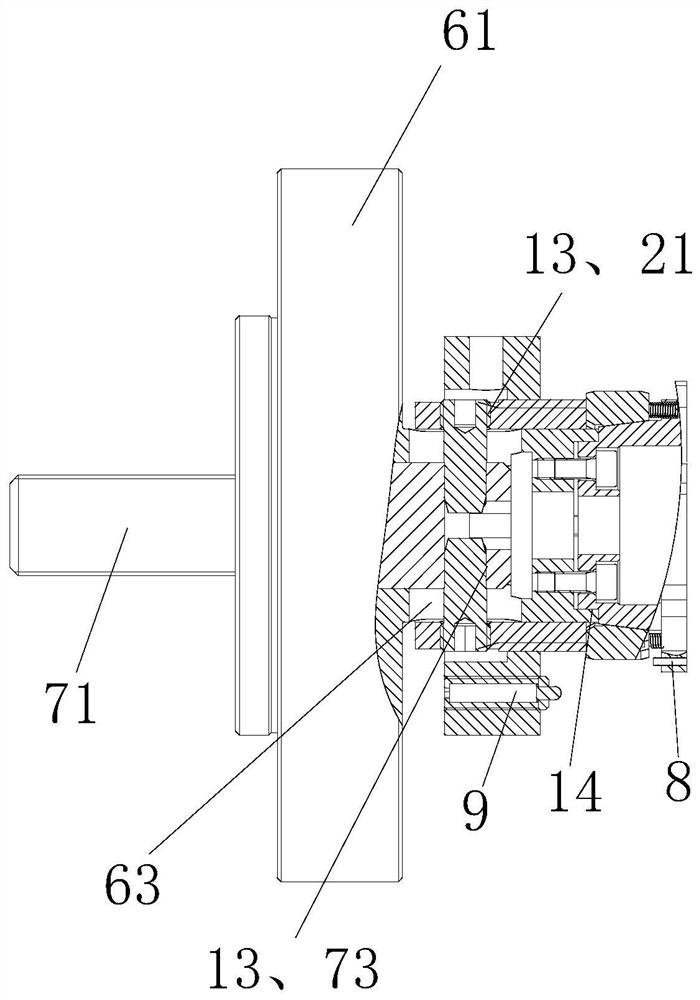

[0027] The present invention's push-type expanding cover fine car fixture, such as Figure 2-11 As shown, it includes flange plate 6, push rod 7, expansion sleeve positioning cone 3, adhesive expansion sleeve 4, six retraction springs 12, push sleeve 2, thread adjustment sleeve 10, two threaded pins 13; push rod 7 The front end 72 of the push rod stretches into the central hole of the flange 6, and the rear end 71 of the push rod stretches out the big end 61 of the flange 6; Frustum structure, the small end 31 of the positioning cone is connected to the small end 62 of the flange 6 by bolts, and the flange 33 at the large end is provided with six external splines 34, and each external spline 34 is upward Extend out an elastic retaining pin 8 afterward; External spline 34 can pass through the spline hole of gear part 1 to be processed; It includes eight elastic joints 41 of non-metallic material and eight conical joints 42 arranged in a staggered manner and glued into a ring; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com