Rapid forming injection mold for transparent part of car lamp

A technology for injection molds and transparent parts, which is applied in the field of rapid prototyping injection molds for transparent parts of automobile lamps, can solve the problems of reducing production efficiency and use safety, unable to accurately control the amount of materials used, and easily scalding workers, etc. Improve space utilization and facilitate post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

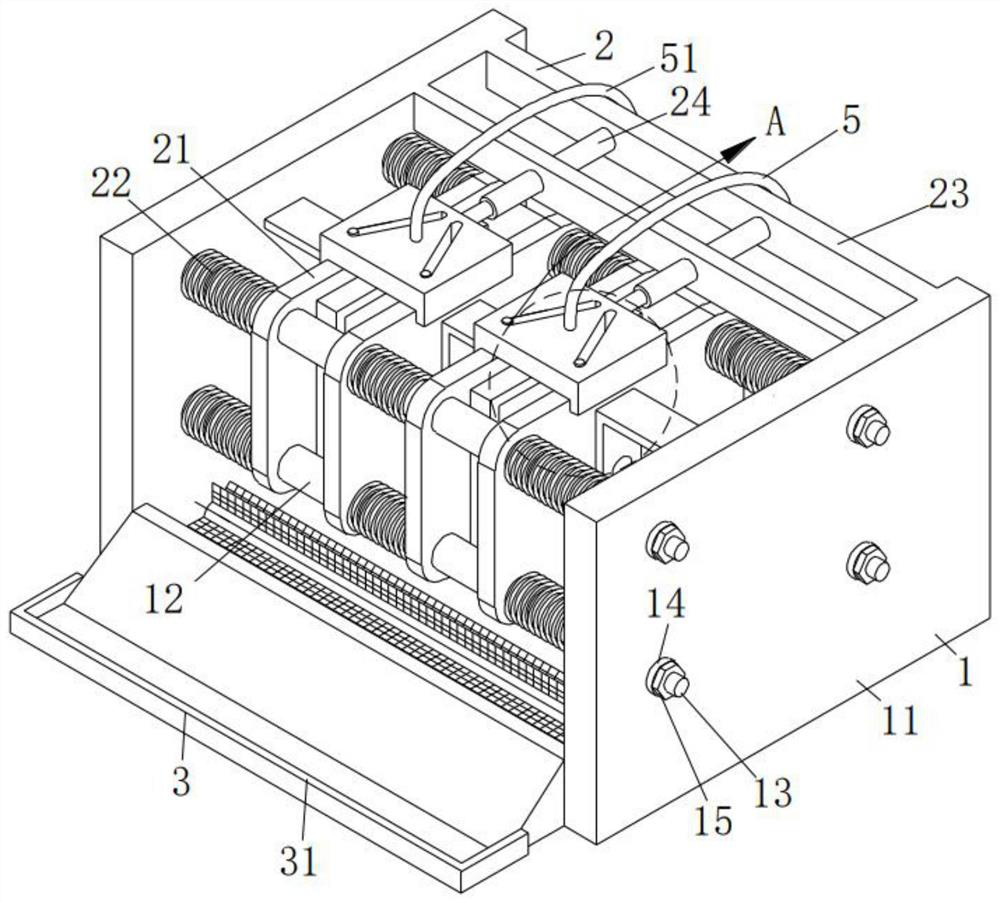

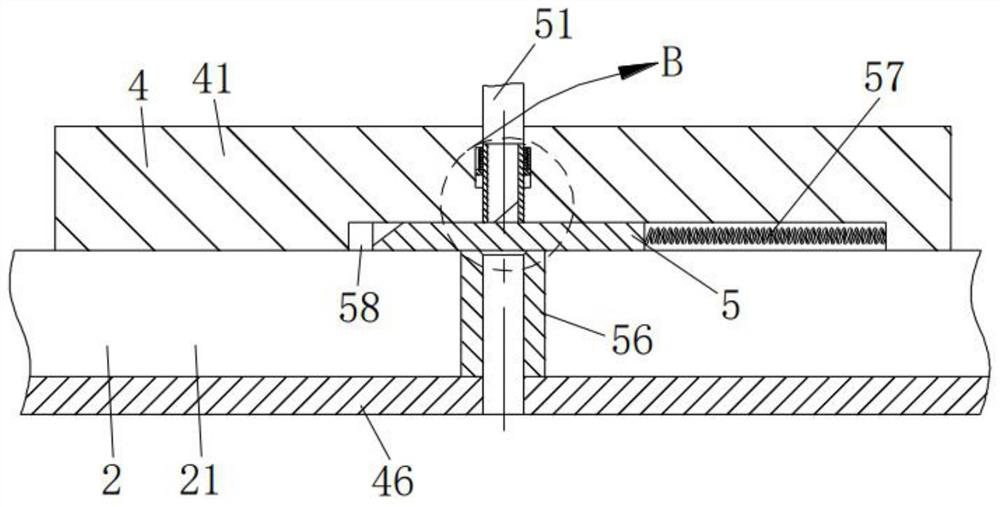

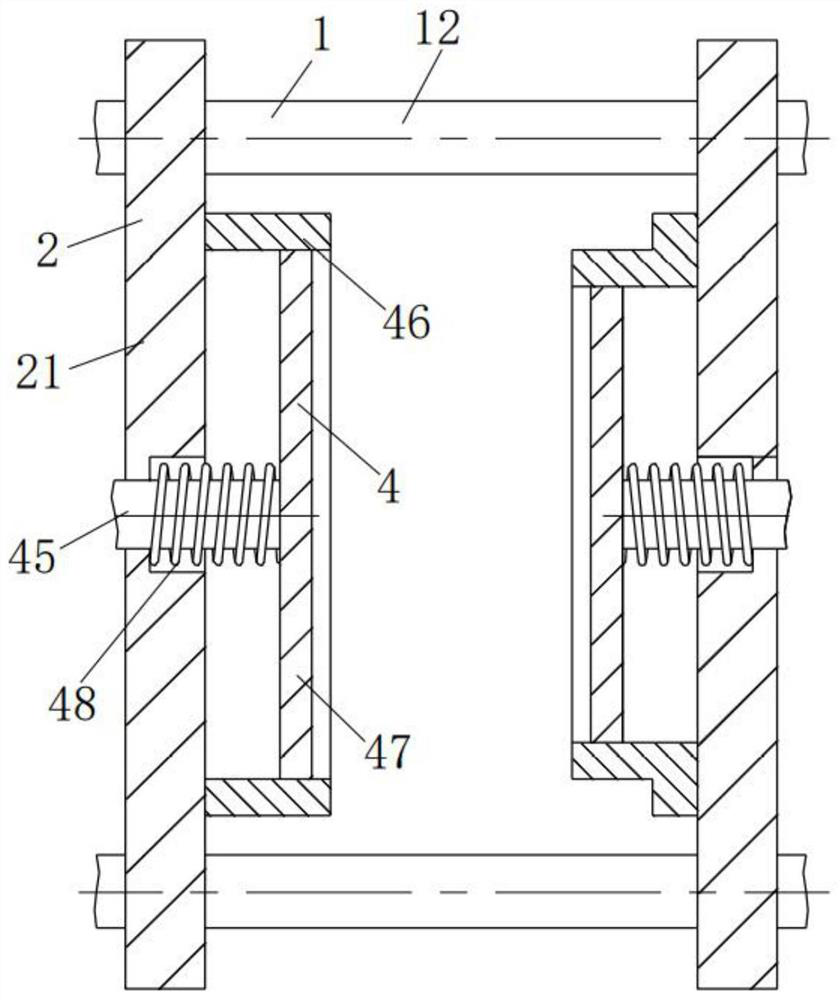

[0029] Such as Figures 1 to 7 As shown, the embodiment of the present invention provides a rapid prototyping injection mold for a car lamp transparent part, including a support mechanism 1, and an auxiliary mechanism 2 is slidably mounted on the support mechanism 1; a cooling mechanism 3 is arranged under the auxiliary mechanism 2; An engaging mechanism 4 is installed on the auxiliary mechanism 2, and the auxiliary mechanism 2 drives the opening and closing mechanism 4; the opening and closing mechanism 4 is connected with a material injection mechanism 5.

[0030] Such as Figures 1 to 7 As shown, the support mechanism 1 includes a support plate 11, a plurality of sliding shafts 12 are arranged between the two support plates 11, and a threaded ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap