Industrial waste gas processing device

A technology for processing devices and industrial waste gas, applied in the direction of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of troublesome intake pipe connection, troublesome wire fixing, inconvenient disassembly and maintenance, etc. Simple and efficient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

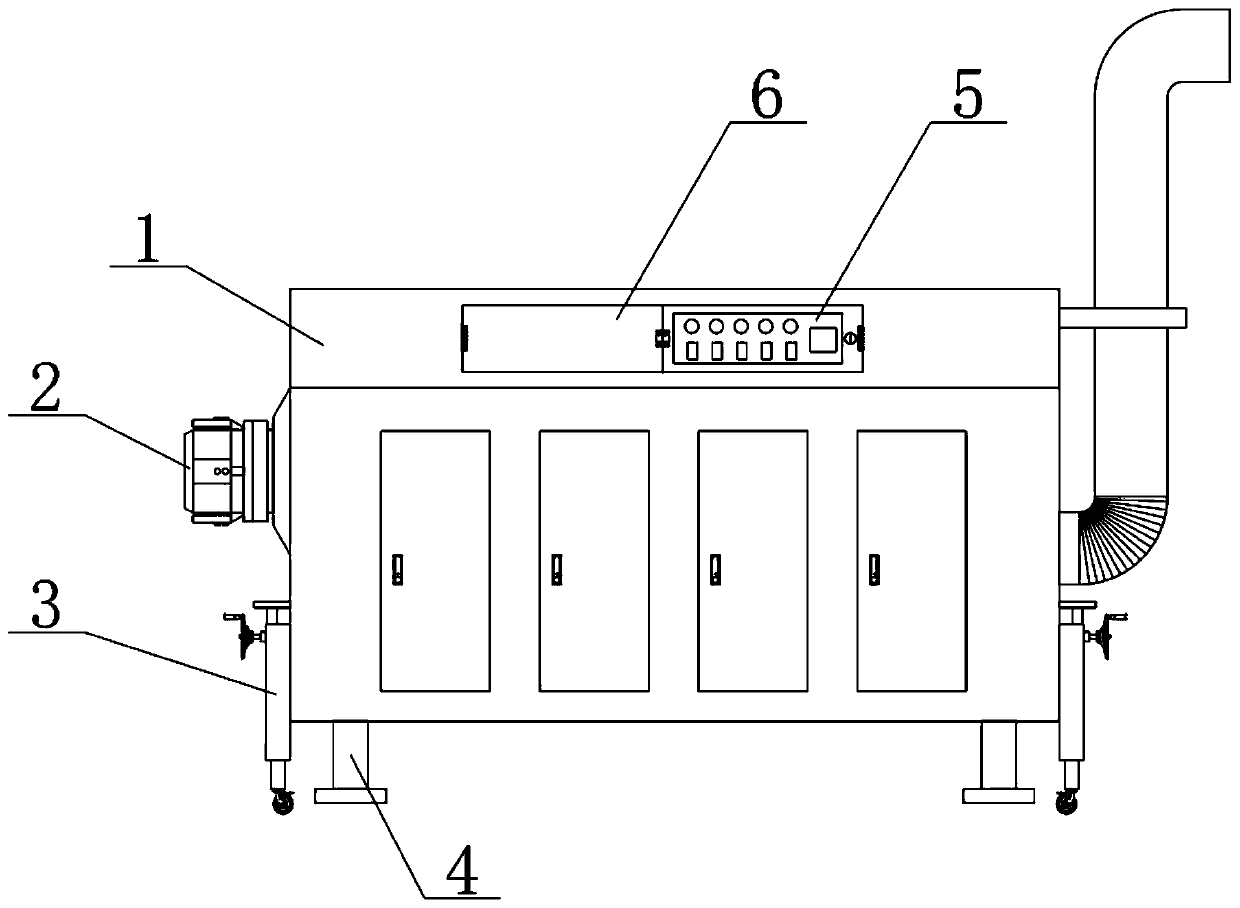

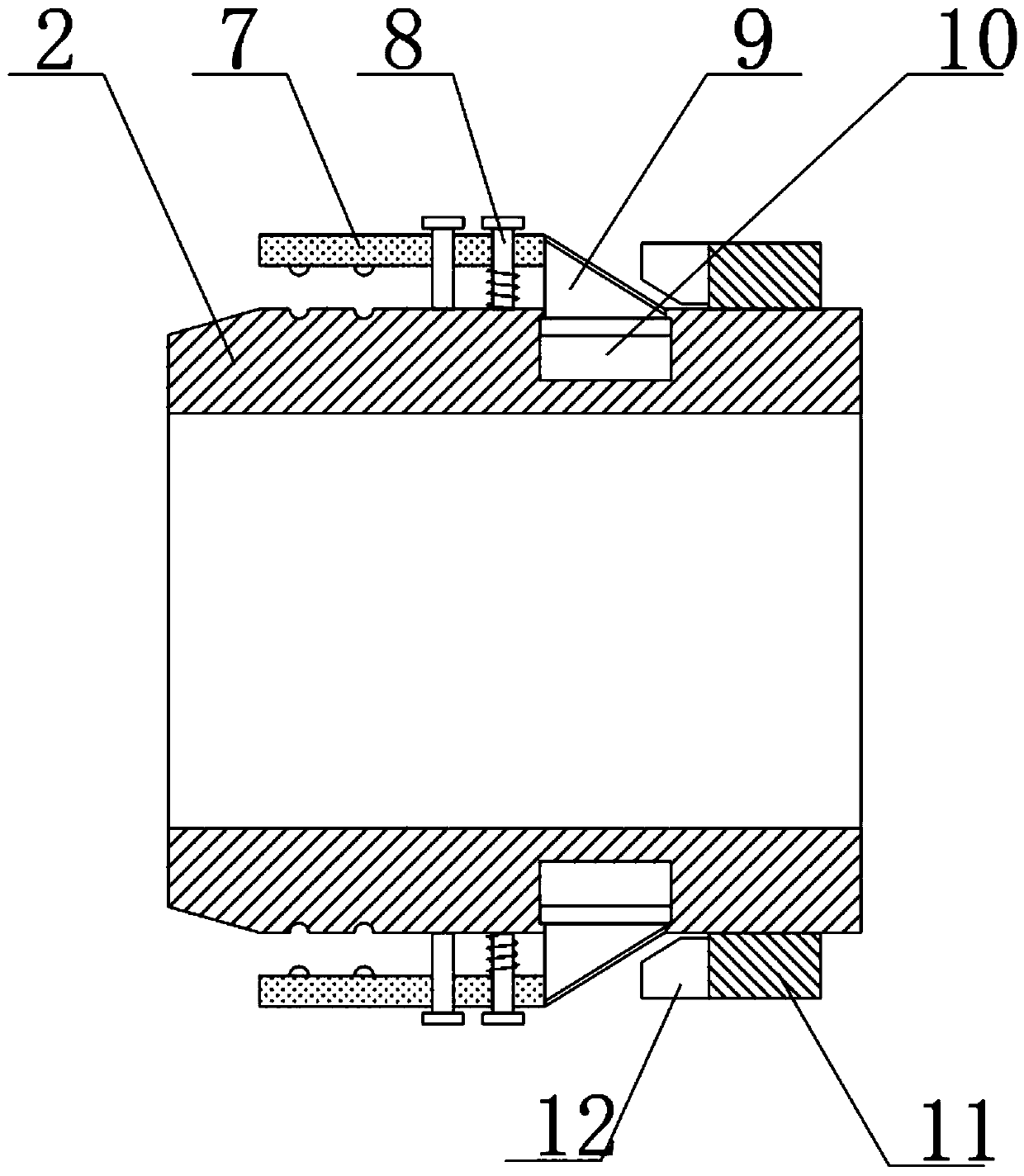

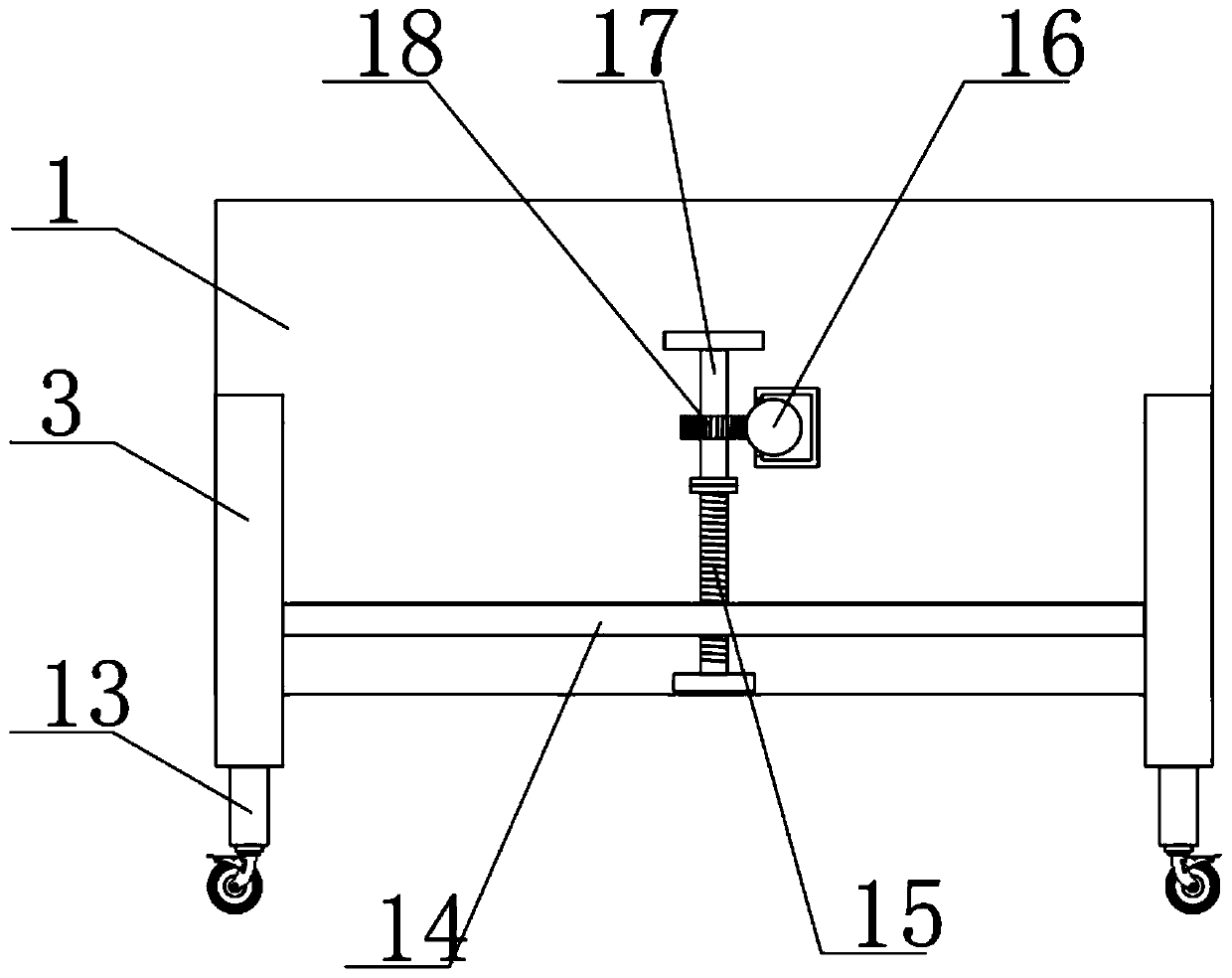

[0021] see Figure 1-Figure 4 , the present invention provides a technical solution: an industrial waste gas treatment device, including a device outer shell 1, the four corners of the lower surface of the device outer shell 1 are fixedly provided with support columns 4, and one end of the device outer shell 1 is provided with an air intake pipe 2, and the other end An exhaust pipe is provided, and the outer surface of the air intake pipe 2 is surrounded by evenly distributed sliding chambers 10, and a slider 9 is slid and embedded in the sliding chamber 10, and the end of the slider 9 protrudes from the sliding chamber 10, and the end One end of the intake pipe 2 is screwed with an internal thread ring 11, and one end of the internal thread ring 11 is welded and fixed with a circular ring 12. There is a gap of 2mm between the circular ring 12 and the intake pipe 2 to avoid The thread on the outer surface of the circular ring 12 and the intake pipe 2 is worn, the inner edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com