Vehicle-mounted guardrail and vehicle

A technology for guardrails and carriage floors, which is applied to vehicle components, upper structures of trucks, and upper structures, etc., can solve problems such as low efficiency, cumbersome installation and disassembly of vehicle guardrails, etc., to achieve improved efficiency, avoid easy confusion, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

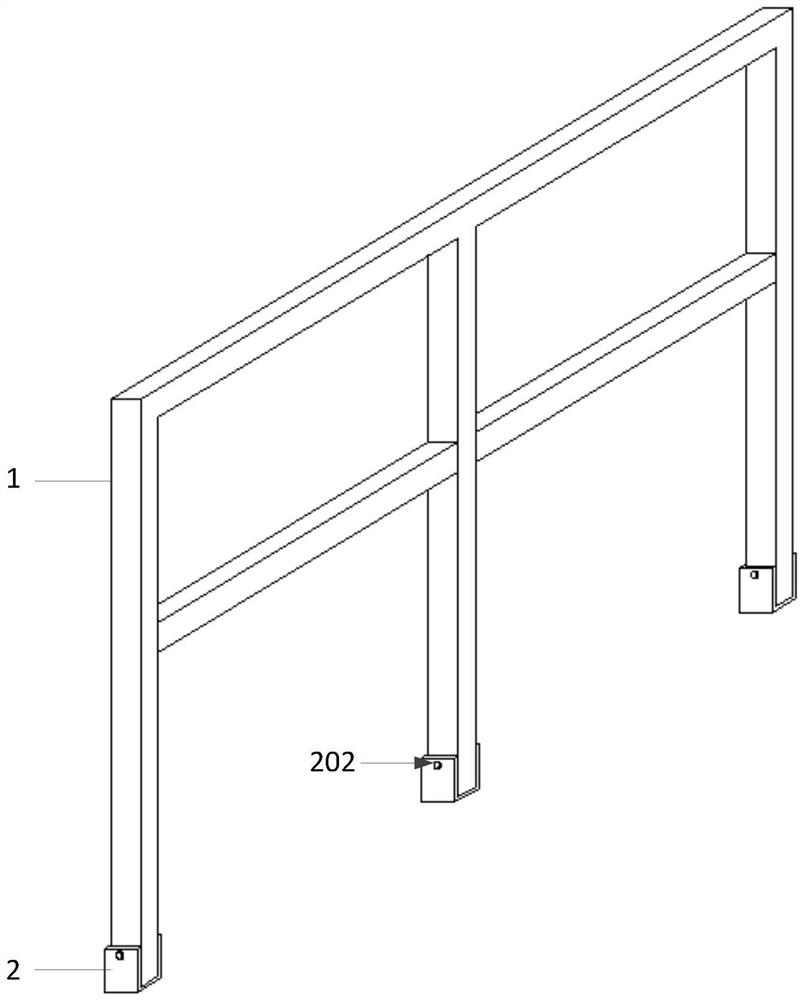

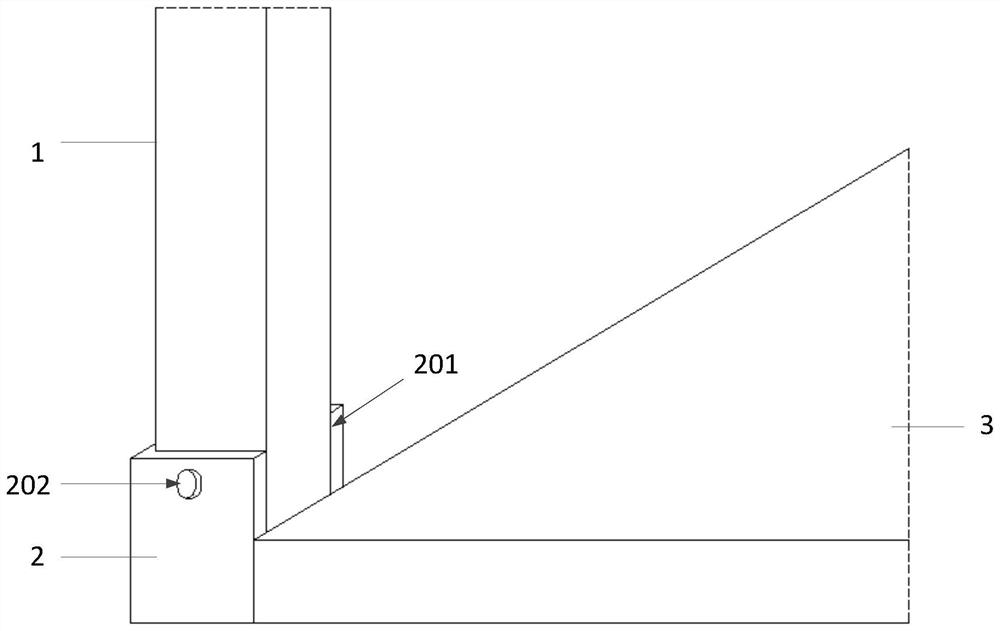

[0037] Reference attached figure 1 - attached Figure 5 , Embodiment 1 of the present invention proposes a vehicle-mounted guardrail, and the vehicle-mounted guardrail includes:

[0038] A plurality of first connectors 2 are installed on the side walls of the compartment floor 3 at intervals;

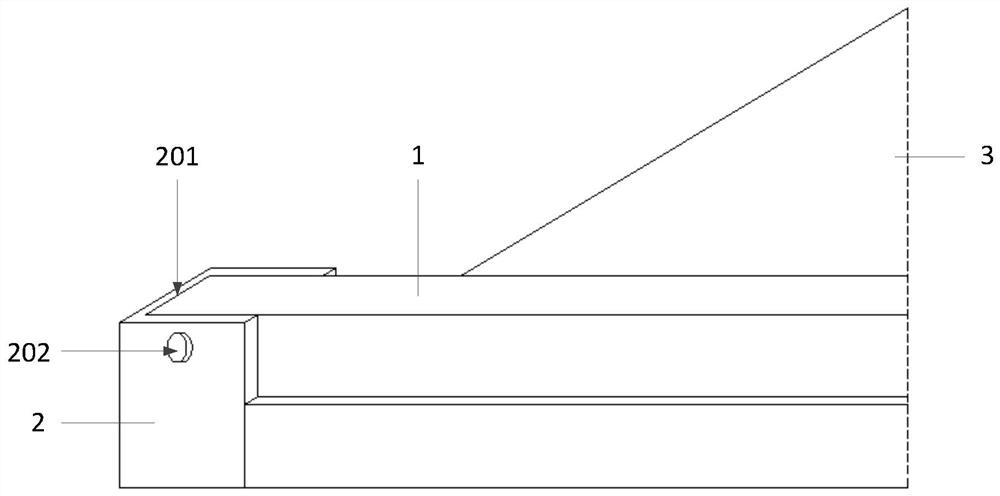

[0039] The guardrail body 1 has at least two connecting ends on its bottom side, which are respectively movably connected with the corresponding first connectors 2, so that the guardrail body 1 has a first state and a second state;

[0040] When the guardrail body 1 is in the first state, the guardrail body 1 is perpendicular to the compartment floor 3 and maintains a relative position with the compartment floor 3;

[0041] When the guardrail body 1 is in the second state, the guardrail body 1 is parallel to and in contact with the compartment floor 3 .

[0042] Specifically, the vehicle-mounted guardrail proposed in this embodiment can be applied to the field of petroleum gas seal d...

Embodiment 2

[0064] Reference attached figure 2 , Embodiment 1 of the present invention proposes a vehicle, which includes: the vehicle-mounted guardrail described above, installed on the side of the compartment floor 3 .

[0065] Specifically, the vehicles provided in this embodiment can be trucks, such as: Beiben trucks 2529 and 2534, but not limited thereto. , the guardrail body 1 can be conveniently switched between the first state and the second state, thereby eliminating the need to disassemble the guardrail body 1 in the non-working state, saving the space required for storing the guardrail body 1, as well as installation and disassembly The time required for the guardrail body 1 can avoid confusion when storing the guardrail body 1, and can effectively improve the efficiency of equipment installation and disassembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com