Device for tightly attaching coiled material packaging materials with different diameters

A technology of packaging materials and coiled materials, which is applied in the field of coiled packaging materials clinging devices, can solve the problems of low product practicability, affecting the protection of the protective plate, and the inability to adjust the fixing device, so as to achieve good protection, improve practicability, Avoid the effect of excessive pauses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

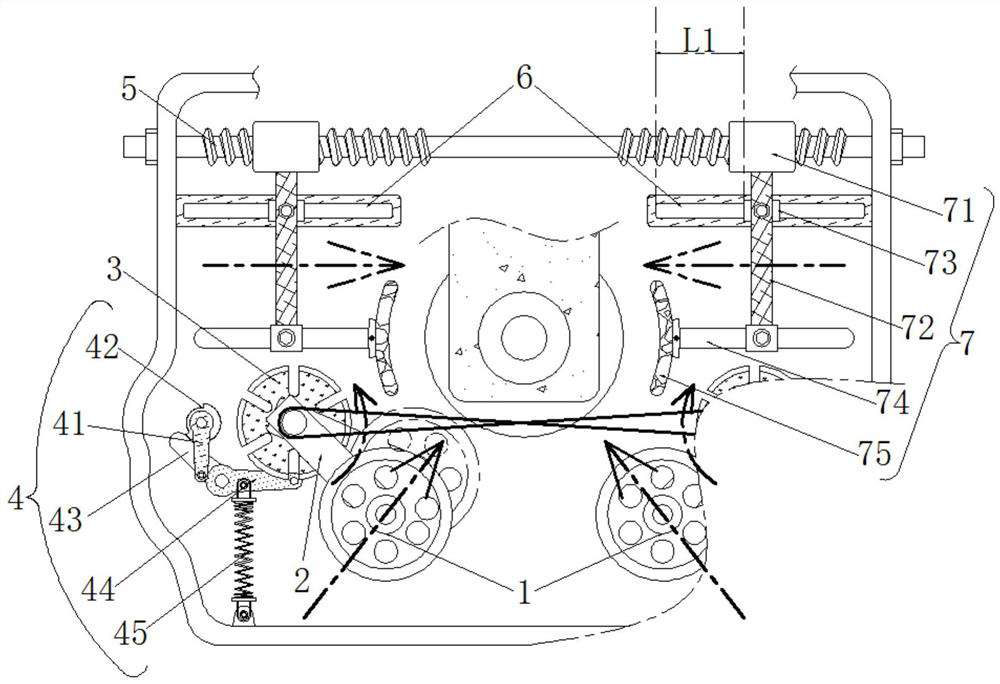

[0024] see Figure 1-2 , a device for sticking coiled packaging materials with different diameters, comprising a round wheel 1, a connecting rod 2 is hinged on the rear side of the round wheel 1, and a runner-3 is movably hinged on the side of the connecting rod 2 away from the round wheel 1, The middle part of the runner-3 is provided with sliding grooves, and there are six sliding grooves, which are symmetrically distributed in the runner-3 according to the center. A two-way threaded rod 5 is movably installed above the runner one 3, and a fixed rod 6 is fixedly installed below the two-way threaded rod 5.

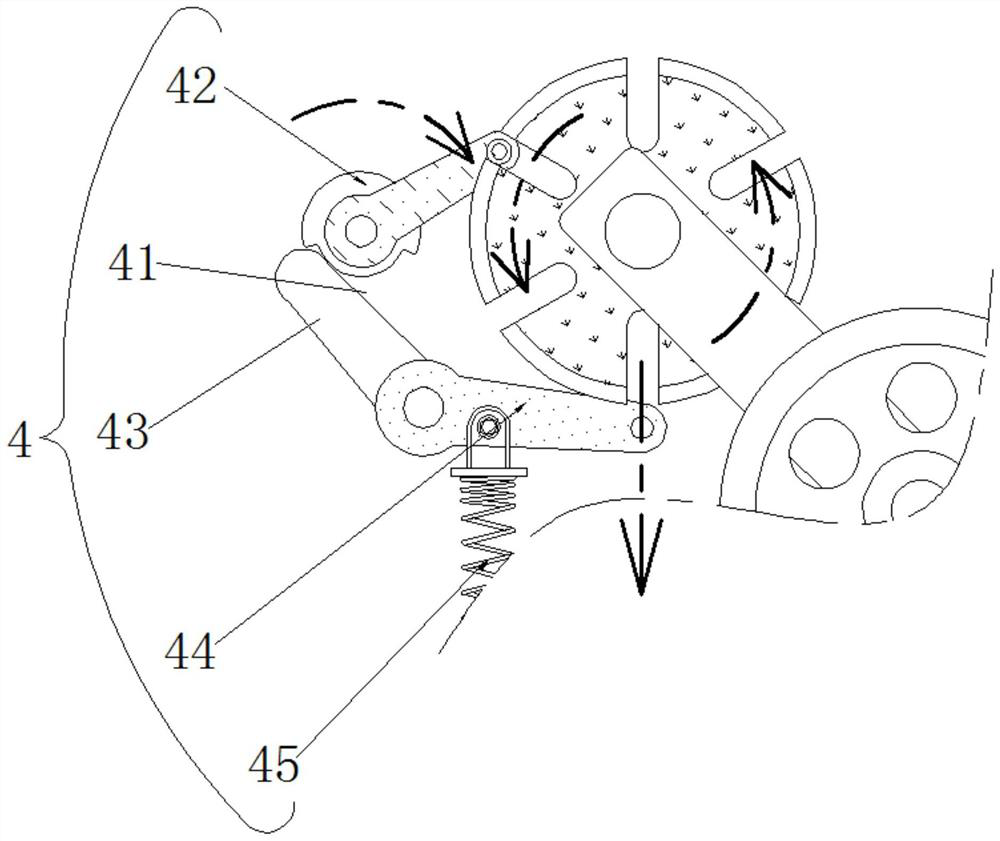

[0025] Comprising rotating device 4, the middle part of rotating device 4 is movably equipped with rotating rod 41, and the rear side of rotating rod 41 is movably installed with irregular runner 42, and the bottom of irregular runner 42 is movably installed with movable rod one 43, and movable rod one The right side of 43 is movably installed with limit bar 44, and irre...

Embodiment 2

[0027] see figure 1 , 3 , a device for sticking coiled packaging materials with different diameters, comprising a round wheel 1, a connecting rod 2 is hinged on the rear side of the round wheel 1, and a runner-3 is movably hinged on the side of the connecting rod 2 away from the round wheel 1, The middle part of the runner-3 is provided with sliding grooves, and there are six sliding grooves, which are symmetrically distributed in the runner-3 according to the center. A two-way threaded rod 5 is movably installed above the runner one 3, and a fixed rod 6 is fixedly installed below the two-way threaded rod 5.

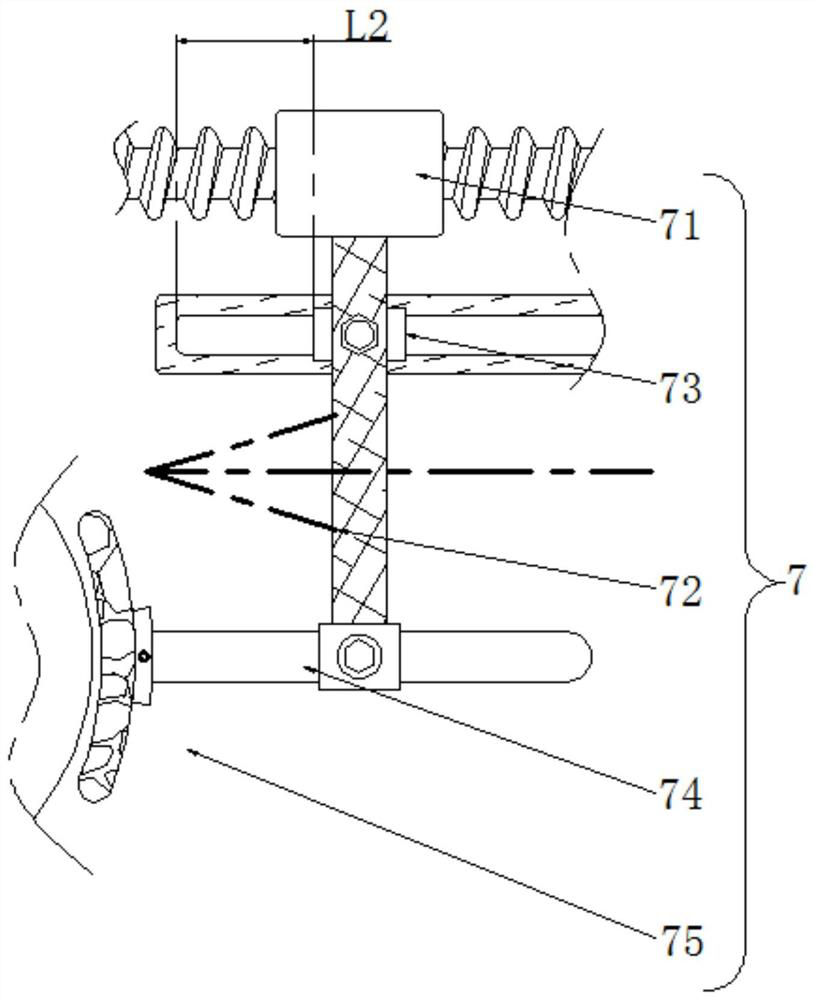

[0028] The top of the round wheel 1 is movably equipped with a fixed structure 7, and the top of the fixed structure 7 is movably equipped with a threaded block 71, and the two-way threaded rod 5 is threadedly connected with the threaded block 71. The bottom of the threaded block 71 is fixedly equipped with a vertical bar 72, the rear side of the vertical bar 72 is fix...

Embodiment 3

[0030] see Figure 1-3 , a device for sticking coil packaging materials with different diameters, including a rotating device 4, a rotating rod 41 is movably installed in the middle of the rotating device 4, and an irregular runner 42 is movably installed on the rear side of the rotating rod 41, and the irregular rotating The bottom of wheel 42 is movably equipped with movable rod-43, and the right side of movable rod-43 is movably installed with limit rod 44, and irregular runner 42 part is set to recess, and the edge place of irregular runner 42 and movable rod-43 The sides of the movable rod 43 are attached to each other, and the left side of the movable rod 43 is hinged with the left side of the stop rod 44. The front side of the right side of the limit rod 44 is welded with a short column. When the limit rod 44 is in a horizontal position, the short column is stuck in the sliding groove, and the top front side of the rotating rod 41 is welded with a push rod, and the posi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap