Gravity-based papermaking efficiency improving device for automatically preparing paper pulp in proportion

A proportional configuration, automatic technology, applied in papermaking, feeding device, textile and papermaking, etc., can solve the problems of abnormal steam temperature, low raw material, insufficient contact reaction, etc., and achieve the effect of reducing the instability of input amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

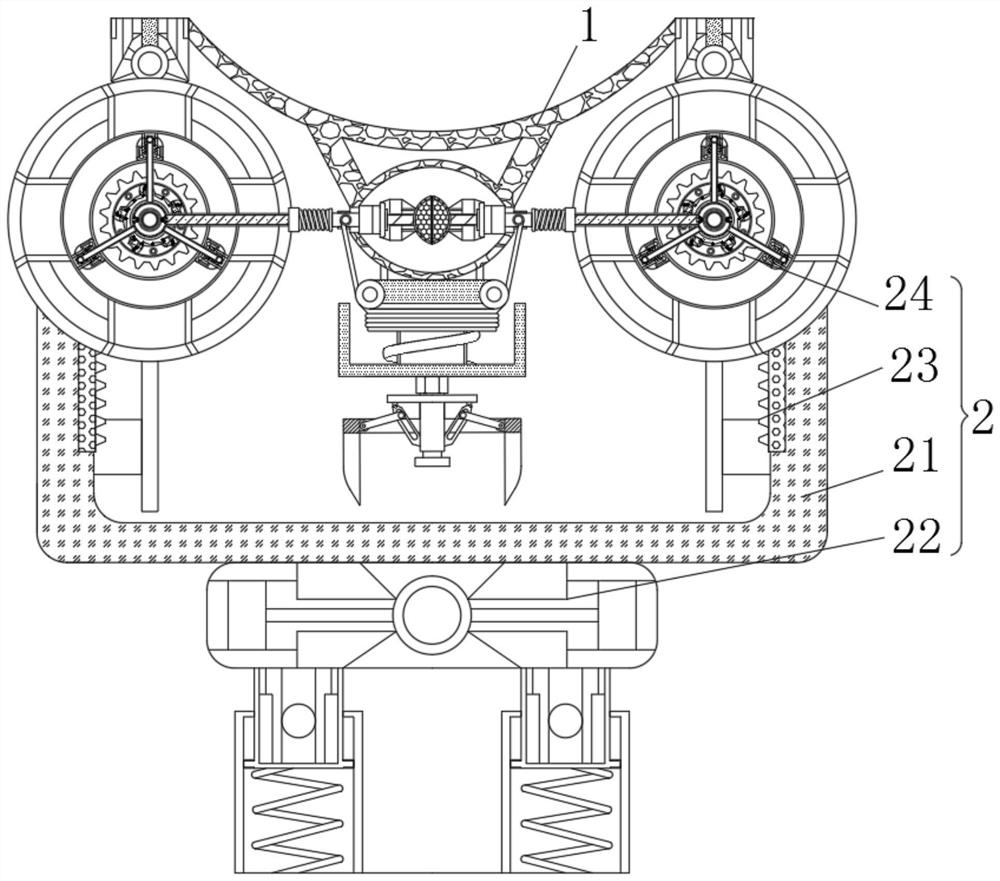

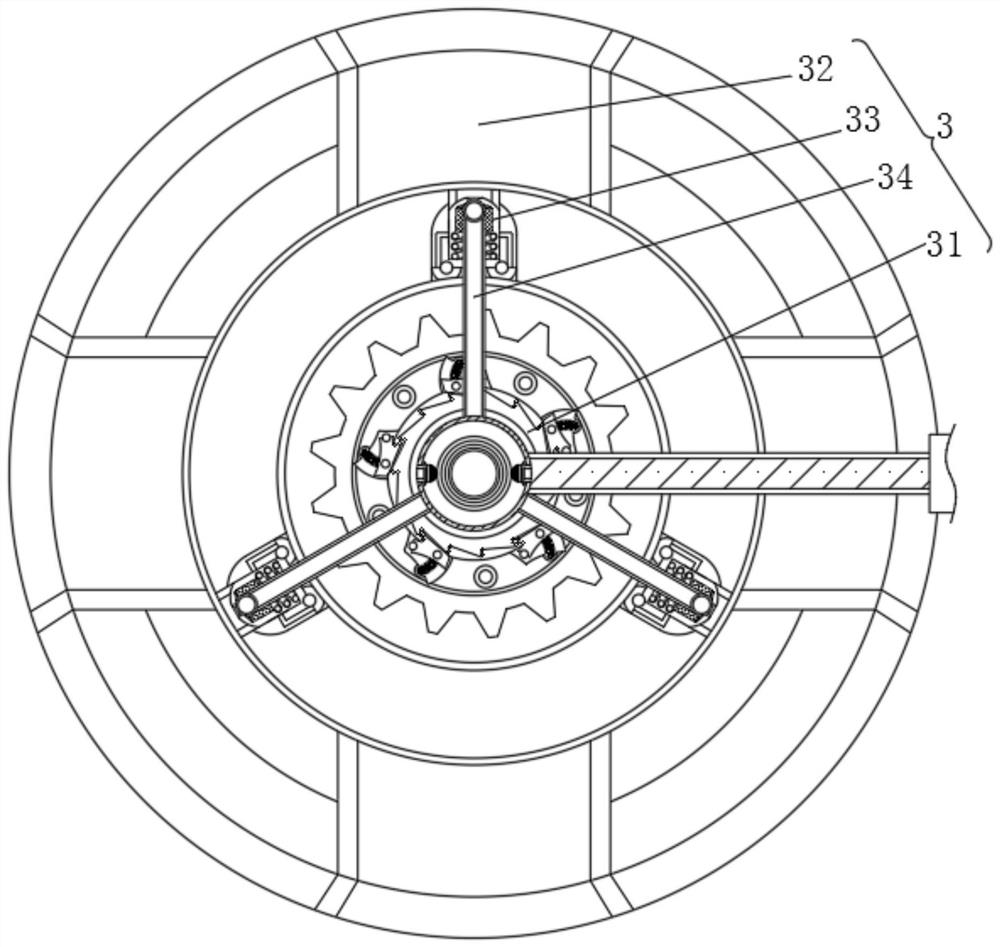

[0026] see figure 1 with figure 2 with image 3 , a gravity-based papermaking efficiency raising device for automatically distributing pulp in proportion, comprising a liquid medicine mechanism 3 and a steam mechanism 4, the liquid medicine mechanism 3 includes a liquid medicine ratchet 31, and the surface of the liquid medicine ratchet 31 is coaxially connected with Liquid medicine runner 32, the inside of medicine liquid runner 32 is movably connected with liquid medicine throwing spring 33 through the chute that offers, and the bottom of medicine liquid throwing spring 33 is fixedly connected with swinging spring, and swinging spring is away from liquid medicine swinging spring 33 One end of one end is fixedly connected with the inside of the liquid medicine runner 32, and the surface of the liquid medicine swing spring 33 is movably connected with a liquid medicine inclined bar 34.

[0027] When the device is in use, the wood material is put into the raw material shell ...

Embodiment 2

[0032] see Figure 4 with Figure 5, a gravity-based papermaking efficiency raising device for automatically distributing pulp in proportion, comprising a liquid medicine mechanism 3 and a steam mechanism 4, the liquid medicine mechanism 3 includes a liquid medicine ratchet 31, and the surface of the liquid medicine ratchet 31 is coaxially connected with Liquid medicine runner 32, the inside of medicine liquid runner 32 is movably connected with liquid medicine throwing spring 33 through the chute that offers, and the bottom of medicine liquid throwing spring 33 is fixedly connected with swinging spring, and swinging spring is away from liquid medicine swinging spring 33 One end of one end is fixedly connected with the inside of the liquid medicine runner 32, and the surface of the liquid medicine swing spring 33 is movably connected with a liquid medicine inclined bar 34.

[0033] Simultaneously, the rotation of the medicinal liquid runner 32 drives the medicinal liquid swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com