Shaft acidification blockage removal method for carbonate rock high-temperature high-pressure gas well

A high temperature and high pressure, carbonate rock technology is applied in the field of acidification and plugging removal of carbonate rock high temperature and high pressure gas wells and carbonate rock reservoir acidification plugging removal, which can solve the problems of many equipment, complicated operation and high cost. , to achieve the effect of improving the flow channel, simple operation and small number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

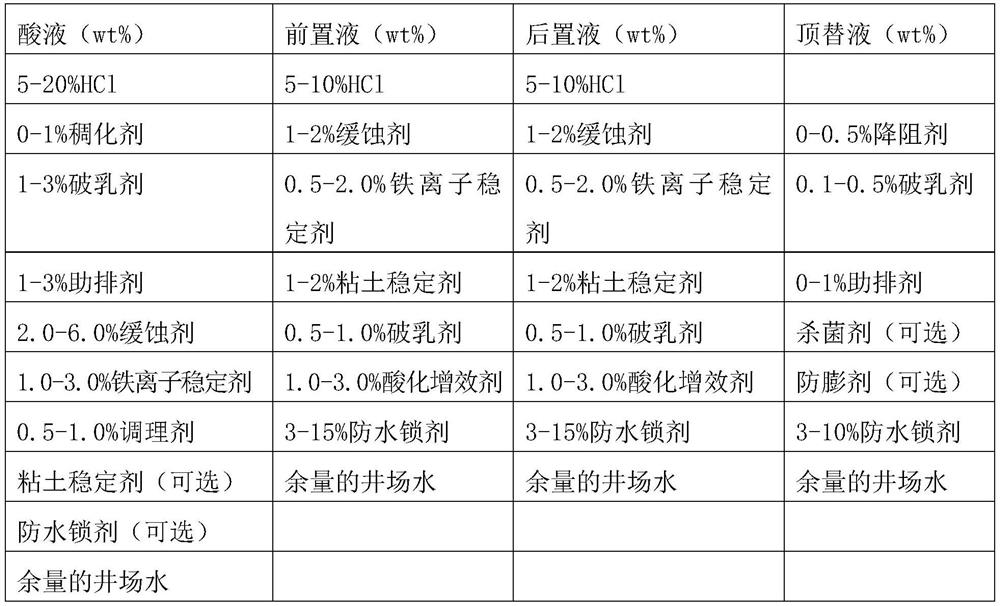

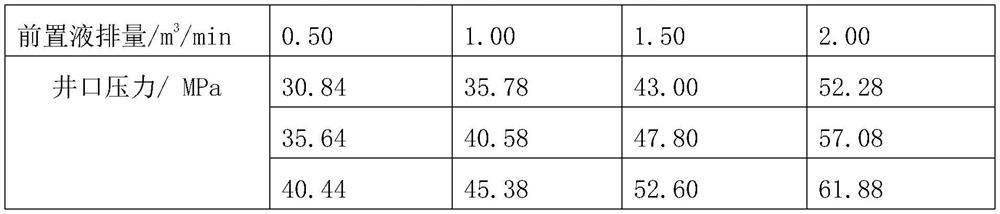

[0075] Example 1A Wellbore Acidizing and Plugging Removal

[0076] Block A belongs to the Keshen gas field, which is a high-temperature and high-pressure carbonate natural gas field. The well A (KeS8-A well) has a depth of 7116 meters, an original formation pressure of 123 MPa, and a bottom hole temperature of about 170 ° C. The thickness of this well is about 70 meters. , the average porosity is about 7%, and the column volume is about 25m 3 ; The oil pressure of the well can reach 97.69MPa in the early stage of production, and the daily natural gas production is about 78.01×10 4 m 3 ; During the production process, the oil pressure output continued to decline due to wellbore blockage. Before the construction of wellbore acidification and plugging removal, the oil pressure of the well dropped to 22.8MPa, and the daily natural gas production was 12.70×10 4 m 3 . It was decided to implement wellbore fixed-point acidizing and plugging removal construction.

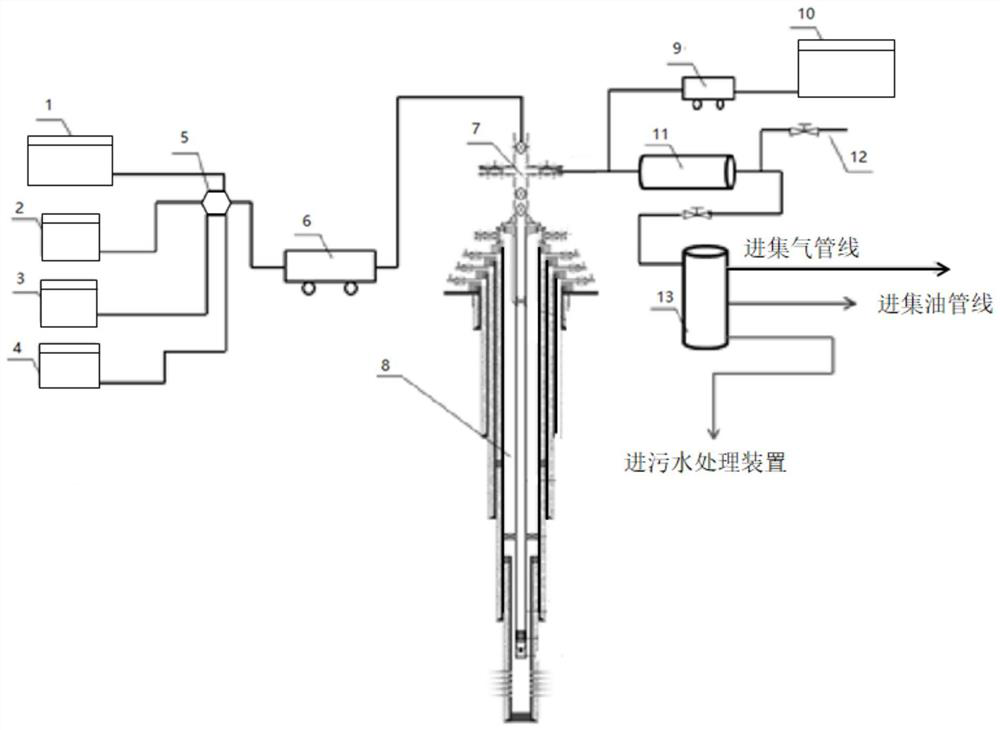

[0077] Installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com