Automobile glass elevating switch button endurance test device and method thereof

A technology for lifting switches and automotive glass, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc. It can solve problems such as failure to meet expected test requirements, failure to meet test standards, damage to switch buttons, etc., to achieve protection Stability, reasonable design, effect of reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

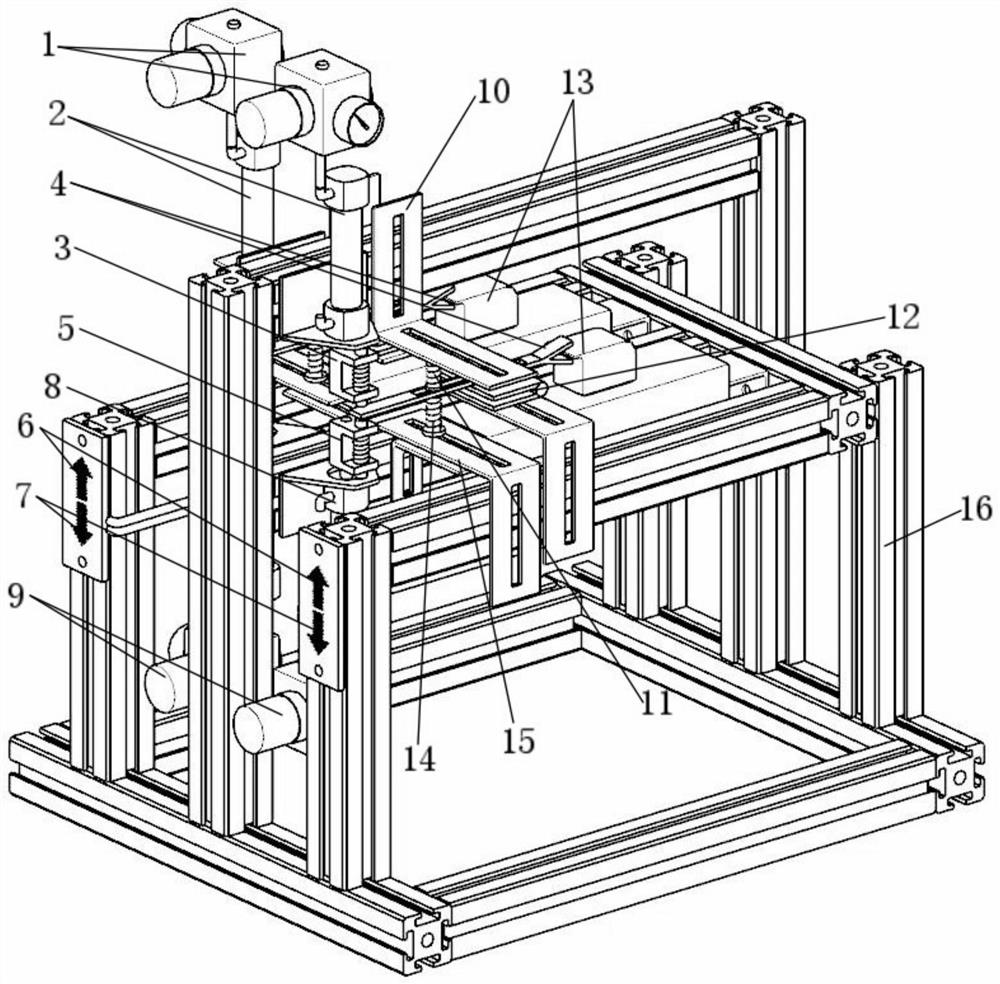

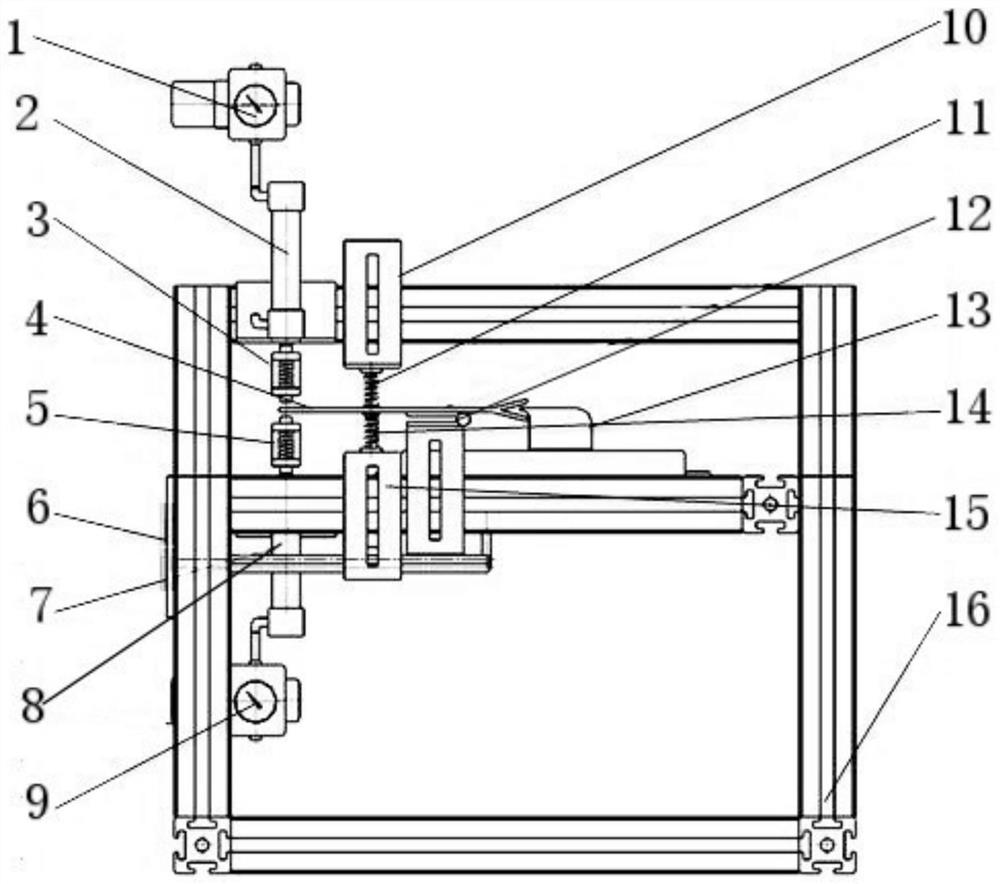

[0026] see Figure 1~2 , a kind of automobile glass lifting switch button durability test device, comprises test bench 16, cylinder, button Y-type lever 4 and lifting switch button 13; Said lifting switch button 13 is arranged on the test bench 16, and said lifting switch The front end of the button 13 is provided with a button Y-type driving rod 4, and the cylinder is fixedly installed on the test bench 16. The cylinder includes an upper dial cylinder 2 and a lower dial cylinder 8, and the movable end of the upper dial cylinder 2 is arranged on the Above the front end of the button Y-shaped driving rod 4, the movable end of the described down dial cylinder 8 is arranged below the front end of the button Y-shaped driving rod 4.

[0027] In the embodiment of the present invention, the test bench 16 is built with aluminum alloy profiles, so that the test bench 16 can be built according to the actual test situation, and then ensure that the lifting switch button is installed on t...

Embodiment 2

[0032] see Figure 1~2 , a kind of automobile glass lifting switch button durability test device, comprises test bench 16, cylinder, button Y-type lever 4 and lifting switch button 13; Said lifting switch button 13 is arranged on the test bench 16, and said lifting switch The front end of the button 13 is provided with a button Y-type driving rod 4, and the cylinder is fixedly installed on the test bench 16. The cylinder includes an upper dial cylinder 2 and a lower dial cylinder 8, and the movable end of the upper dial cylinder 2 is arranged on the Above the front end of the button Y-shaped driving rod 4, the movable end of the described down dial cylinder 8 is arranged below the front end of the button Y-shaped driving rod 4.

[0033] In the embodiment of the present invention, the top of the button Y-shaped lever 4 is also provided with a lever upper limit plate 10 fixedly installed on the test bench 16, and the button Y-shaped lever 4 and the lever upper limit A lower ret...

Embodiment 3

[0036]A test method for a durability device of an automobile glass lift switch button, the test method for the device includes:

[0037] 1) Install the test sample, the Y-type lever of the test tool, and the upper and lower brake cylinders, and realize the lifting action of the lifting switch button through the principle of leverage;

[0038] 2) Install the upper and lower return springs to realize that the Y-shaped lever can return to the middle position after turning the paddle switch, and at the same time reduce the impact force of the cylinder during the cylinder braking process, effectively ensuring the stability of the test sample;

[0039] 3) Install and adjust the upper and lower brake cylinders, and use the cylinder telescopic brake Y-shaped lever to form a lever principle to realize the action of the lifting switch button;

[0040] 4) Fix the Y-shaped lever, and ensure that the lever is on the central axis as much as possible when pushing the button, without tilting....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com