Polarizing laminate and image display device including the same

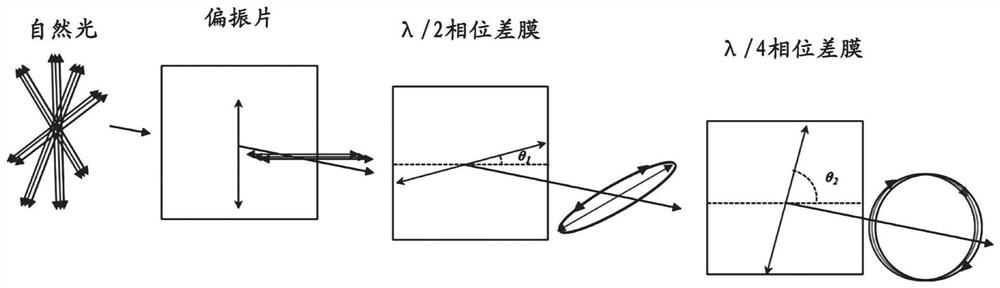

A technology of image display device and polarizing layer, which is applied in the direction of identification device, optics, optical elements, etc., can solve the problems of not being able to see the original image well, scattering, and inability to ensure, so as to achieve external light reflection characteristics and improve folding properties , the effect of suppressing color interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0125] Pellets of ZEONOR 1420 (manufactured by Zeon Co., Ltd., Japan) as a norbornene resin were dried at 100° C. for 5 hours.

[0126] The above-mentioned pellets are fed into an extruder, melted in the extruder, then passed through a polymer tube and a polymer filter, and then extruded in sheet form from a T-die onto a casting drum and cooled to obtain a thickness A non-extensible film of 40 μm.

[0127] The above-mentioned non-stretched film was continuously supplied to a tenter, and the first stretch was performed at a feeding angle of 45°, a stretching temperature of 140°C, and a stretching ratio of 1.3 times, thereby obtaining an average angle of 45° with respect to the winding direction. The oriented first elongated film is then wound on a winding core.

[0128] The above-mentioned first elongated film was turned over, and supplied to a tenter so as to be oriented in a direction of 90° with respect to the orientation angle of the first elongated film, at a feeding angl...

preparation example 2

[0130] Pellets of ZEONOR 1420 (manufactured by Nippon Zeon Co., Ltd.), which is a norbornene resin, were dried at 100° C. for 5 hours.

[0131] The above-mentioned pellets are fed into an extruder, melted in the extruder, then passed through a polymer tube and a polymer filter, and then extruded in sheet form from a T-die onto a casting drum and cooled to obtain a thickness A non-extensible film of 13 μm. The detailed properties of the films are shown in Table 1 below.

preparation example 3

[0133] All the processes described in Preparation Example 1 were carried out in the same manner except that the elongation ratio was changed to 1.5 times. The second elongated film obtained was a diagonally elongated film with a thickness of 22 μm, the detailed properties of which are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com