Multicolour light-emitting dispersed type electroluminescence lamp

A technology of light-emitting lamps and luminous bodies, which is applied in the direction of electroluminescent light sources, light sources, electric light sources, etc., and can solve problems such as color interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

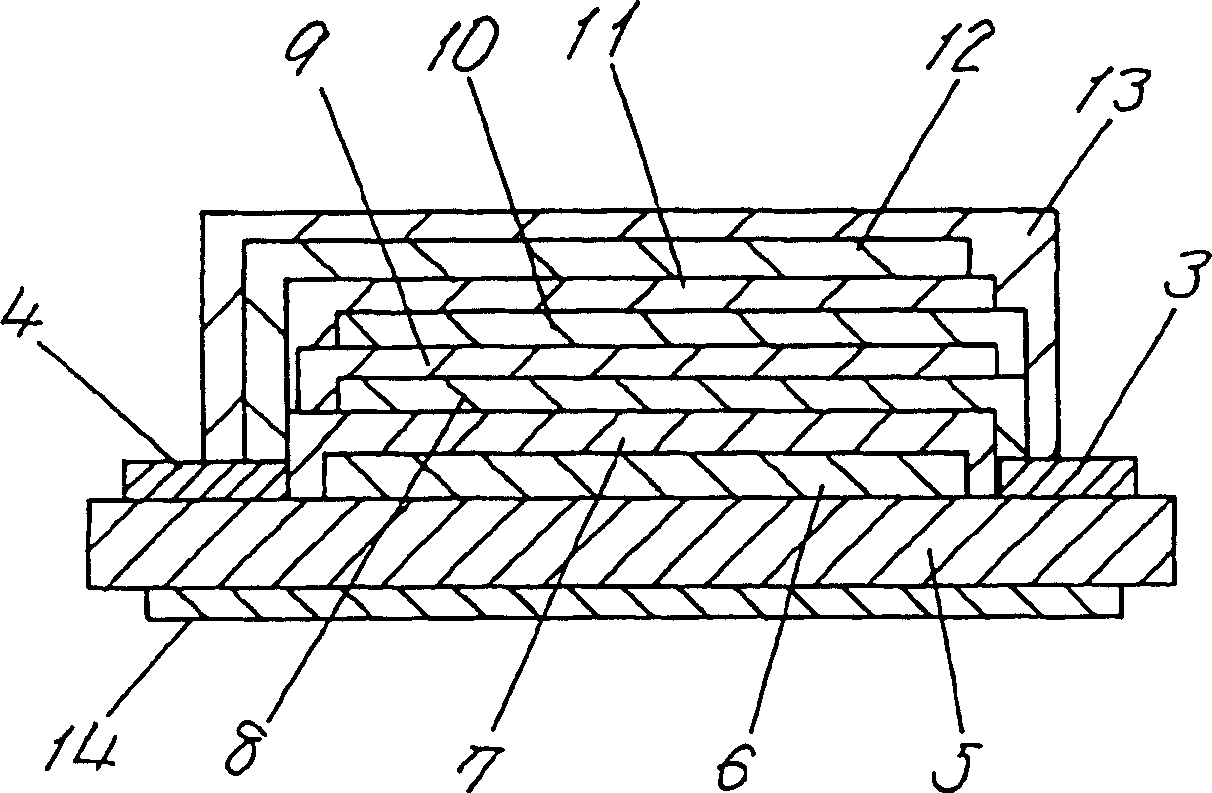

[0141] figure 1 A sectional view showing a polychromatic emission dispersion type EL lamp according to a first exemplary embodiment of the present invention. exist figure 1 Among them, the multi-color light-emitting dispersion type EL lamp has: a transparent resin film 5, a first translucent electrode layer 6 disposed on the first surface side of the transparent resin film 5, a first translucent electrode layer 6 disposed on the first translucent electrode layer 6 A luminous body layer 7, a second light-transmitting electrode layer 8 disposed on the first light-emitting body layer 7, a luminous color conversion layer 9 disposed on the second light-transmissive electrode layer 8, and a luminous color conversion layer 9 disposed on the The third light-transmitting electrode layer 10 on the third light-transmitting electrode layer 10, the second light-emitting body layer 11 on the third light-emitting body layer 10, the back electrode layer 12 on the second light-emitting body...

Embodiment 2

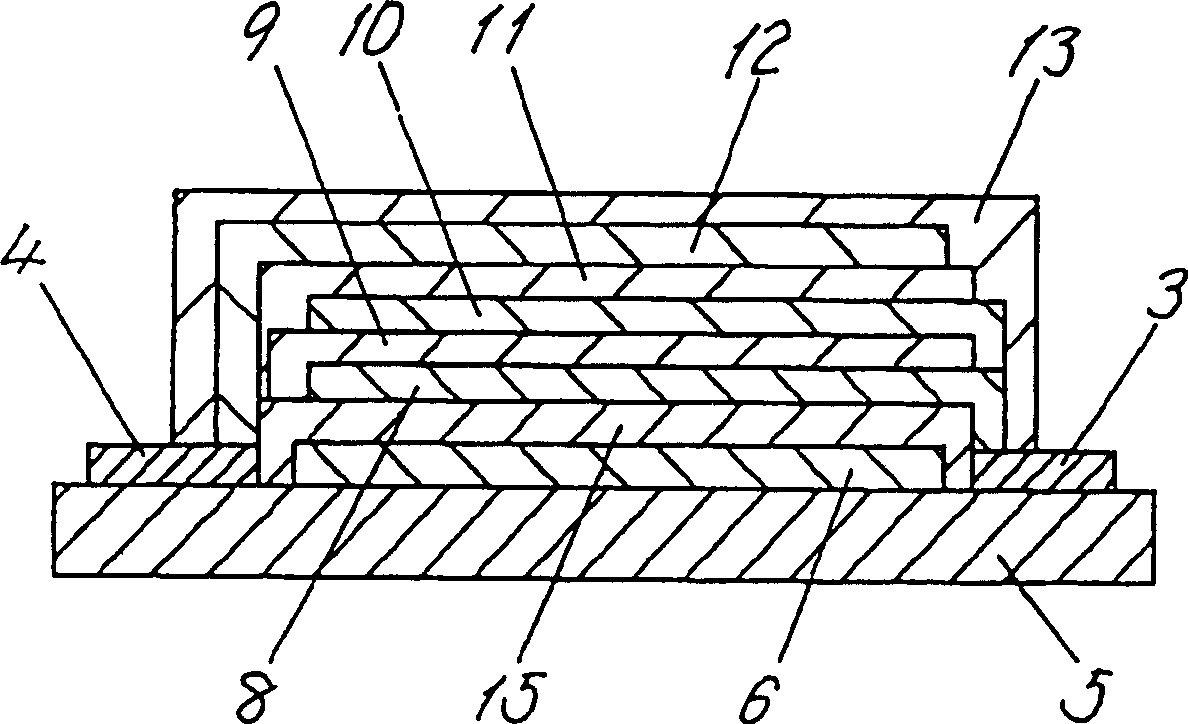

[0163] figure 2 A cross-sectional view showing a polychromatic emission dispersion type EL lamp according to a second exemplary embodiment of the present invention. exist figure 2 Among them, the multi-color light-emitting dispersion type EL lamp has: a transparent resin film 5, a first translucent electrode layer 6 disposed on the first surface side of the transparent resin film 5, a first translucent electrode layer 6 disposed on the first translucent electrode layer 6 A luminous body layer 15, the second light-transmitting electrode layer 8 disposed on the first light-emitting body layer 15, the luminous color conversion layer 9 disposed on the second light-transmissive electrode layer 8, and the luminous color conversion layer 9 The third light-transmitting electrode layer 10 on the third light-transmitting electrode layer 10, the second light-emitting body layer 11 on the third light-emitting body layer 10, the back electrode layer 12 on the second light-emitting body ...

Embodiment 3

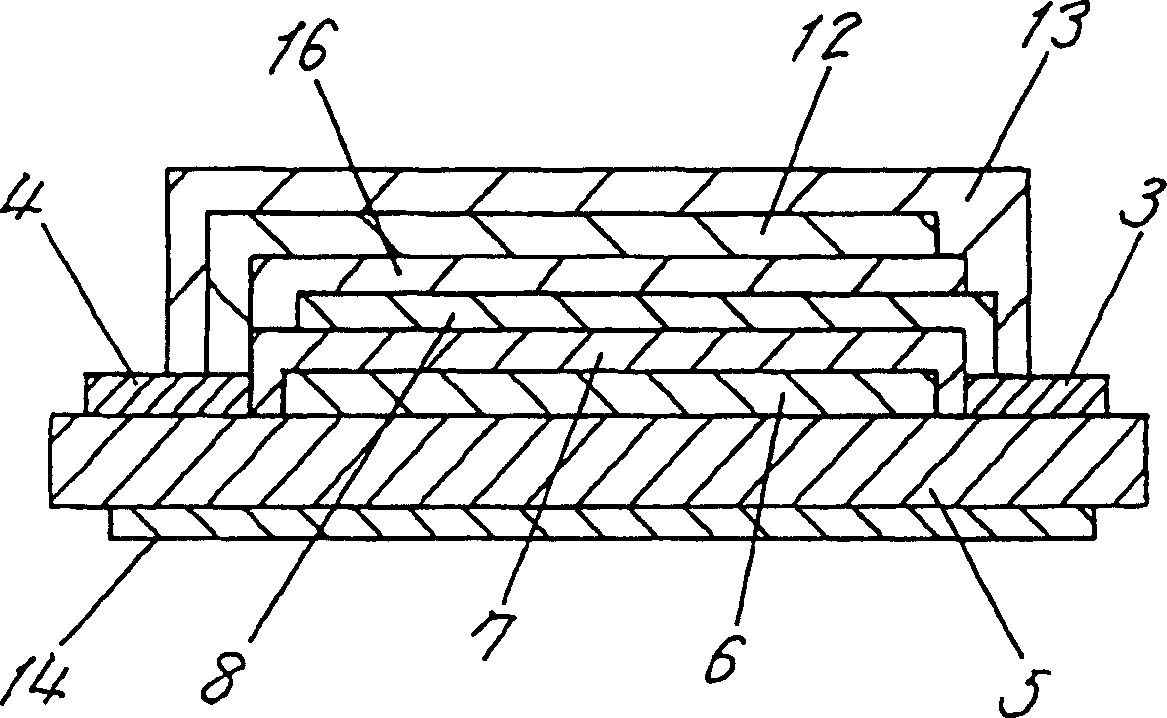

[0175] image 3 A sectional view showing a polychromatic emission dispersion type EL lamp according to a third exemplary embodiment of the present invention. because image 3Among them, the multi-color light-emitting dispersion type EL lamp has: a transparent resin film 5, a first translucent electrode layer 6 disposed on the first surface side of the transparent resin film 5, a first translucent electrode layer 6 disposed on the first translucent electrode layer 6 A luminous body layer 7, the second light-transmitting electrode layer 8 arranged on the first light-emitting body layer 7, the second light-emitting body layer 16 arranged on the second light-transmitting electrode layer 8, and the second light-emitting body layer 16 arranged on the second light-emitting body layer The back electrode layer 12 on the layer 16 is arranged to cover the insulating protective layer 13 of the above-mentioned multiple layers, the color coating layer 14 arranged on the second surface side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com