A Composite Control Method for Hot-press Furnace Temperature Based on Improved Time-Delay Observer

A delay observer and composite control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as system instability, and achieve the effect of speeding up the response speed and improving the anti-disturbance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

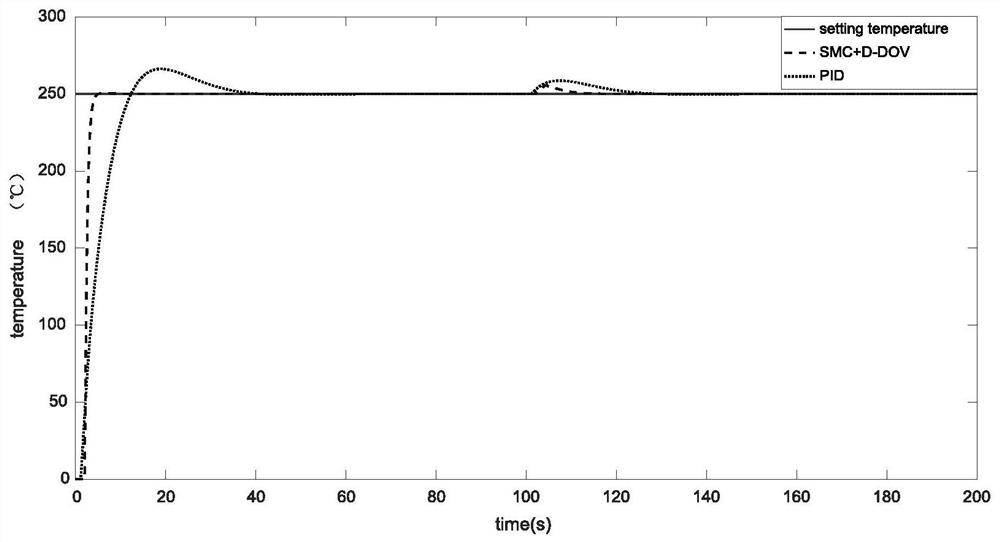

[0024] The specific solution of the present invention to solve the technical problem is: adopt the method of sliding mode control to quickly and accurately make the hot-press furnace system reach the required temperature, and effectively solve the problem caused by the time delay through the design of the time-delay observer. Unfavorable effects, and use the disturbance observer to complete the compensation for the system disturbance.

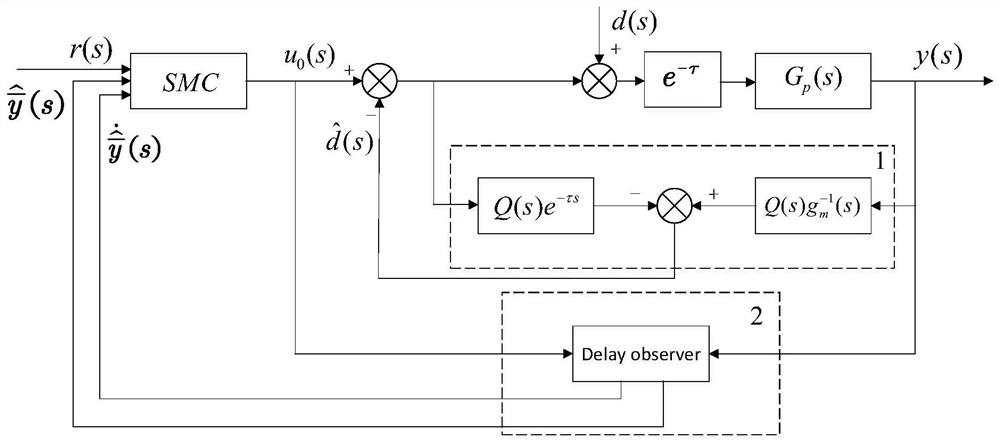

[0025] like figure 1 Shown is the block diagram of the composite control system of hot-press furnace temperature based on the improved time-delay observer, in which, SMC is the sliding mode controller; d(s) is the system disturbance; virtual box 1 is the disturbance observer; virtual box 2 is the delay time observer; G p (s) is the actual accused object; and are the disturbance observation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com