Forward design method of photovoltaic panel steel frame structure

A design method and steel frame technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as lack of designers, no design solutions, and unavailable products, so as to improve technical and economic performance, The effect of reducing the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

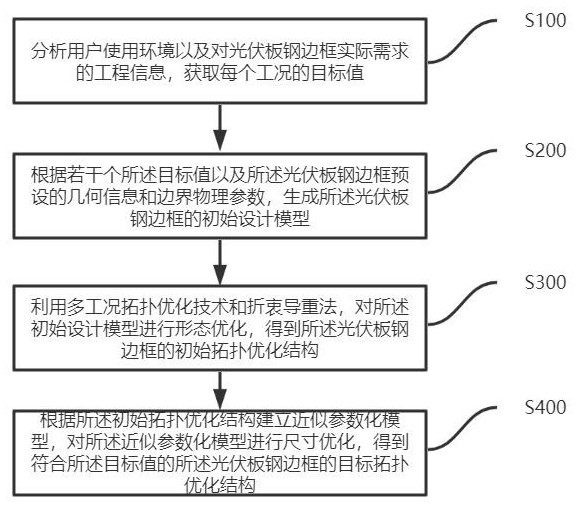

[0056] An embodiment of the present invention, such as figure 1 As shown, the present invention provides a forward design method for a steel frame structure of a photovoltaic panel, including:

[0057] S100 analyzes the user's use environment and the engineering information of the actual demand for the steel frame of the photovoltaic panel, and obtains the target value of each working condition.

[0058] Specifically, investigate the field environment and user needs of the steel frame structure of solar photovoltaic panels, collect basic data that meet user needs, process the data to obtain preset geometric information and boundary physical parameters, and analyze the engineering conditions of the working conditions , to determine the target value of each working condition. Basic data include: product appearance (frame size, section form), anti-corrosion requirements (corrosion resistance), installation method and weight of the whole set, and working conditions include: main...

Embodiment 2

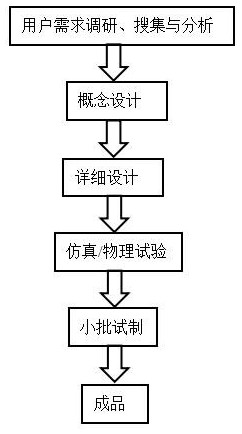

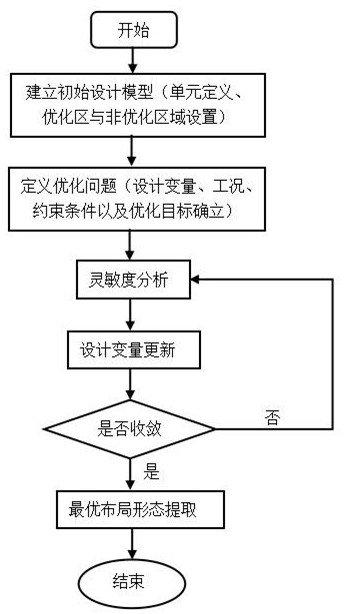

[0067] Based on the above-mentioned embodiment, the parts that are the same as those in the above-mentioned embodiment in this embodiment will not be described one by one. This embodiment provides a forward design method for a steel frame structure of a photovoltaic panel, such as Figure 2~6 shown, including:

[0068] S100 analyzes the user's use environment and the engineering information of the actual demand for the steel frame of the photovoltaic panel, and obtains the target value of each working condition.

[0069] Specifically, investigate the field environment and user needs of the steel frame structure of solar photovoltaic panels, collect basic data that meet user needs, process the data to obtain preset geometric information and boundary physical parameters, and analyze the engineering conditions of the working conditions , to determine the target value of each working condition. Basic data include: product appearance (frame size, section form), anti-corrosion requ...

Embodiment 3

[0122] Based on the above-mentioned embodiment, the same parts as the above-mentioned embodiment in this embodiment will not be described one by one. This embodiment provides a forward design device for a steel frame structure of a photovoltaic panel, such as Figure 7 shown, including:

[0123] The analysis module 701 is used to analyze the user's use environment and the engineering information of the actual demand for the steel frame of the photovoltaic panel, and obtain the target value of each working condition.

[0124] The generating module 702 is configured to generate an initial design model of the steel frame of the photovoltaic panel according to preset geometric information and boundary physical parameters.

[0125] The initial module 703 is configured to perform shape optimization on the initial design model by using the multi-working-condition topology optimization technology and the compromise guide weight method, so as to obtain the initial topology optimization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com