Method for measuring and calculating filling material line in blast furnace opening charge combined calculation

A filling material and material line technology, which is applied in computer material science, manufacturing calculation system, chemical statistics, etc., can solve the problems of large variation, affecting the loading of furnace materials and the preparation process of furnace opening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

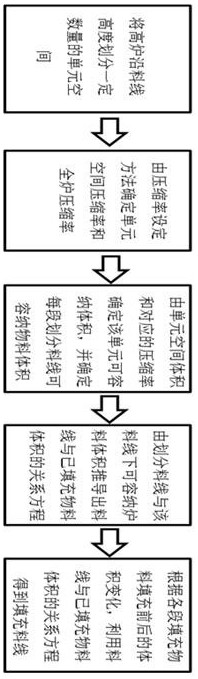

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention are further described below through examples, but the specific embodiments of the present invention are not limited to the following examples.

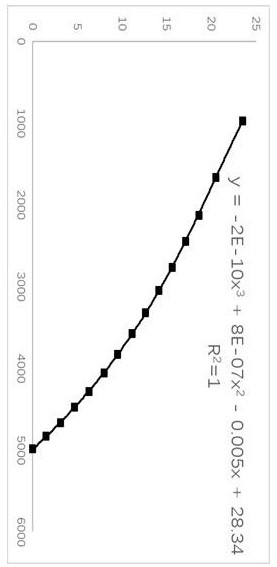

[0034] Taking the combined calculation process of a blast furnace charge as an example, the blast furnace is divided into 15 sections in terms of height, and the volume and compression ratio of each section are shown in the following table:

[0035] Table 1 Calculation of Blast Furnace Compression Ratio

[0036]

[0037] 1. The first calculation

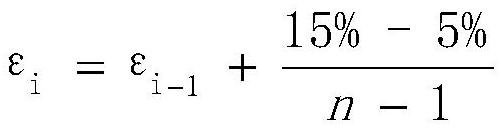

[0038] (1) Calculation of the compression ratio of each section

[0039] As shown in Table 1, the blast furnace is divided into 15 sections along the height, and the material lines of each section are shown in Table 1, and the compression ratio of the first section ε 1 5%, the 15th segment compression ratio ε 15 is 15%, use the calculation formula (1) to calculate the compression ratio of each segment:

[0040] Stage 2 compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com