Method capable of rapidly reaching yield after small and medium maintenance of blast furnace

A blast furnace and high-capacity technology, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve problems such as frequent pipes, slippery materials, and frequent suspensions, affecting the stability of blast furnaces, and irregular operating furnace shapes, and achieve good results. and economic benefits, good mobility, and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

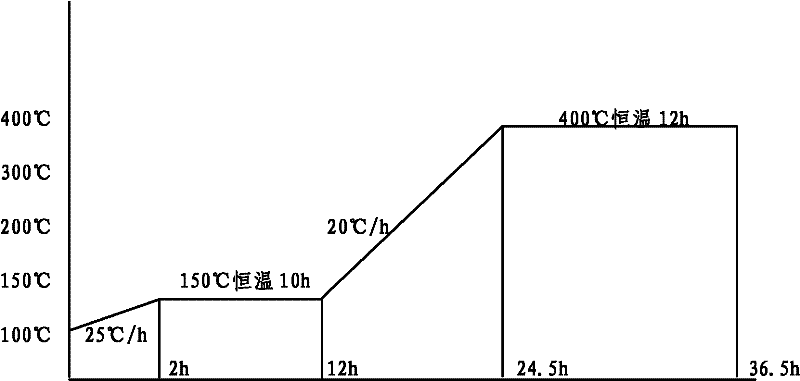

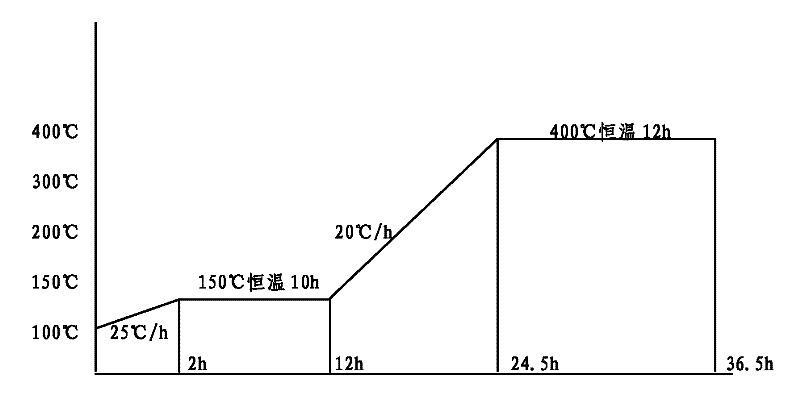

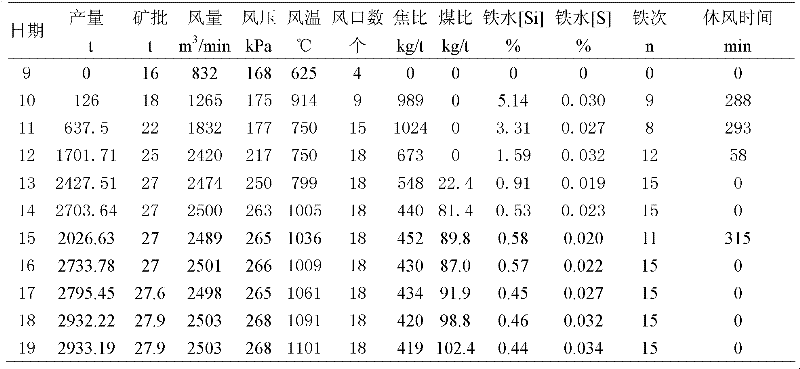

[0014] The method for rapidly reaching production capacity of the blast furnace after minor and medium repairs in the present invention needs to go through three stages: shutdown, minor and medium repairs and start-up. Among them: before the shutdown, the furnace conditions were adjusted as follows: Four days before the shutdown, fluorite (mainly composed of calcium fluoride CaF 2 ) 0.09-0.15 tons / batch, manganese ore 0.8-0.9 tons / batch, maintain the [Mn]% at 0.9-1.05%, and control the [Si]% at 0.50%-0.65% during the furnace washing period; the coke ratio increased one day before the shutdown To 625±20kg / t, the ore batch is 25.6±2 tons / batch; add 25±1 tons of cover coke on the material surface before the pre-shutdown, and the 10 batches of coke before the pre-shutdown are covered. The ratio is 900±20kg / t; the [Si]% of the day before the shutdown of the furnace is 0.85%-1.00%, and the binary alkalinity of the slag is controlled by 1.05-1.10.

[0015] At the same time, the oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com