Printed circuit board production method

A technology for printed circuit boards and production methods, which is applied in the directions of laminated printed circuit boards, printed circuits, printed circuit manufacturing, etc., can solve the problems of increasing the production cost of circuit boards, scrapping auxiliary frames, and being unable to reuse them, so as to reduce production cost, reduce usage, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

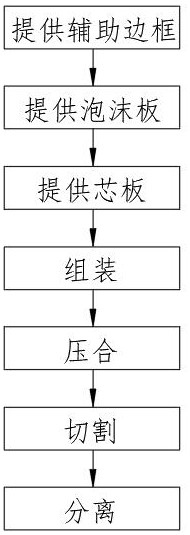

[0044] Such as Figure 1 to Figure 11 Shown, a kind of printed circuit board production method comprises the following steps:

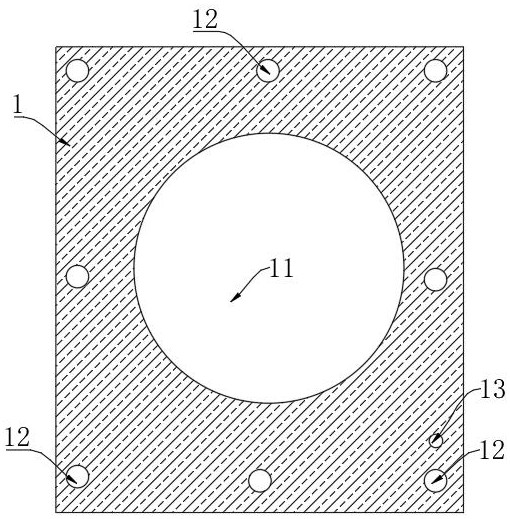

[0045] (1) An auxiliary frame 1 is provided, and a cavity 11 is opened in the middle of the auxiliary frame 1 .

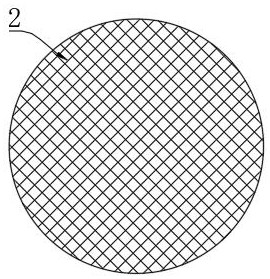

[0046] (2) A foam board 2 is provided, the outer shape of the foam board 2 matches the inner shape of the cavity 11 . In this embodiment, the thickness of the foam board 2 is greater than that of the auxiliary frame 1 .

[0047] (3) A core board 3 is provided. The middle part of the core board 3 has a wiring area 31 , and the range of the wiring area 31 is smaller than the shape range of the foam board 2 .

[0048] (4) Assembling, use the assembly tool to place the foam board 2 in the cavity 11. At this time, there is a gap between the outer wall of the foam board 2 and the inner wall of the cavity 11, so as to facilitate the remaining foam board 2 and auxiliary frame after cutting the finished circuit board 1 separation. In this embod...

Embodiment 2

[0057] Such as Figure 10 As shown, aluminum sheets 5 are provided above the core board 3 and below the auxiliary frame 1 during lamination. The covered area of the aluminum sheet exceeds the edge of the foam board 2 so as to completely cover the wiring area 31 . It can not only protect the wiring area 31 on the surface of the core board 3 , but also prevent the wiring area 31 from being scratched or crushed. At the same time, it also acts as a buffer, which can slow down the contact speed between the pressing plate of the hot pressing device and the core plate 3, so that the pressure is more moderate and uniform, thereby improving the pressing quality.

Embodiment 3

[0059] Such as figure 2 , Figure 4 As shown, the auxiliary frame 1 is provided with a plurality of positioning holes 12 , and the positioning holes 12 are distributed around the cavity 11 at intervals. The core board 3 is provided with pin holes 32 corresponding to the positioning holes 12 .

[0060] When assembling, use the pin shaft 6 to pass through the positioning hole 12 and the corresponding pin hole 32 at the same time. In order to improve the relative position accuracy of the core board 3 and the auxiliary frame 1, and at the same time prevent the relative movement of the core board 3 and the auxiliary frame 1 during pressing.

[0061] preferred, such as Figure 10 As shown, the length of the pin shaft 6 is shorter than the thickness of the laminate assembly, so as to avoid the excessive length of the pin shaft 6 from affecting the thickness of the finished printed circuit board. Because when the length of the pin shaft 6 is greater than the thickness of the lami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com