Method for improving surface quality of die forging

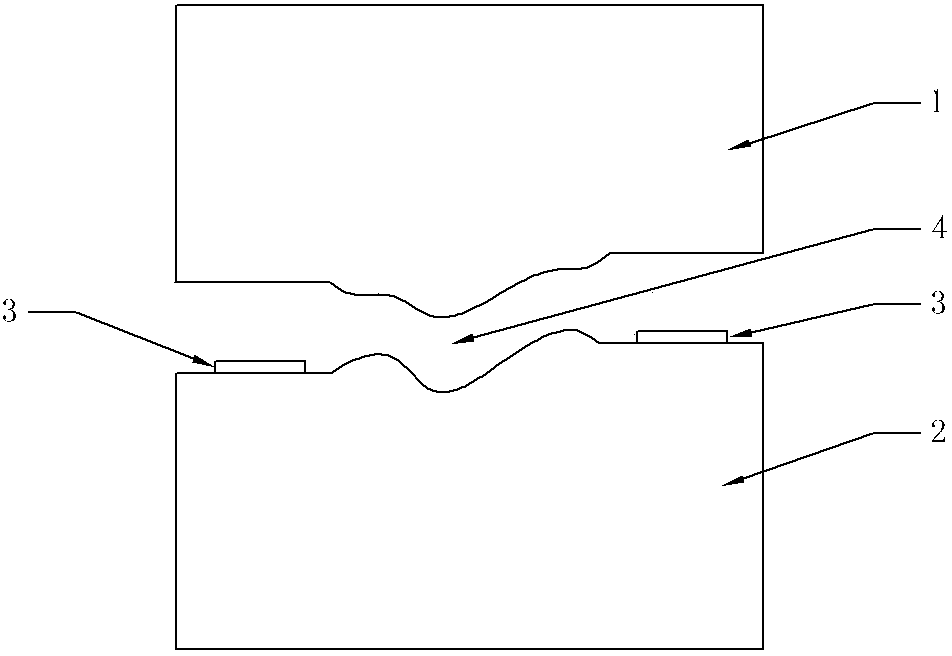

A technology of surface quality and die forgings, which is applied in the forging of stainless steel blade forgings and stainless steel die forgings. The effect of fire times, avoiding insufficient machining allowance for forgings, and preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

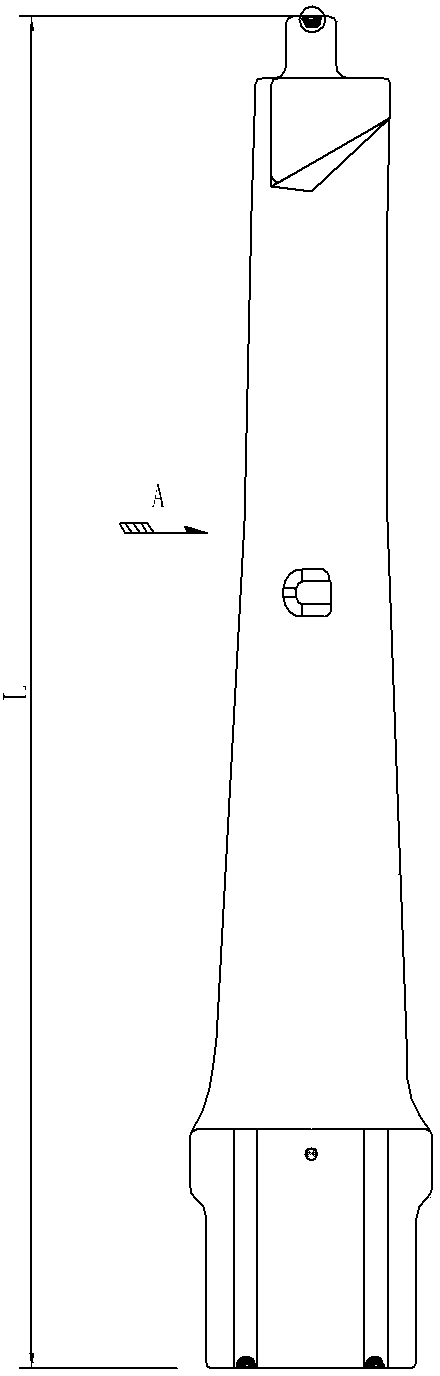

[0026] Process a long blade whose length L is 900mm, its structure see figure 2 , figure 2 Middle A is the air inlet side of the blade. The forging heating temperature is set to 1130°C, and the temperature is kept for 30-60 minutes. The mold is designed according to the center difference of the forging. strike forging;

[0027] After forging, the surface of the forging is cleaned. First, the blade is shot blasted with 1.2mm diameter alloy steel shots, and then the defect parts of the blade are polished. It is required to remove all defects such as edges, folds, and burrs.

[0028] After polishing, thermal shaping is carried out. The thermal shaping temperature is 1130°C, and the holding time is 15-30 minutes (half of the original time). During the thermal shaping, the 2mm thick contact plate is removed, and one-shot molding is performed.

[0029] After the hot shaping, the blades are shot blasted again with alloy steel shots. After the shot blasting, visual inspection is c...

Embodiment 2

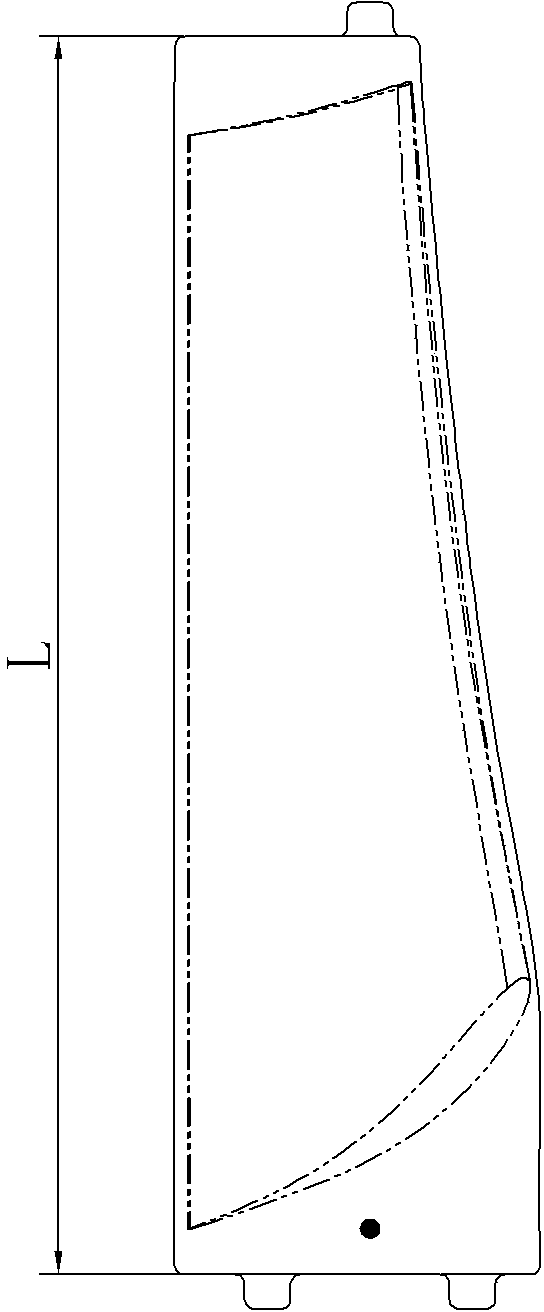

[0032] Process a long blade whose length L is 600mm, its structure see image 3 , the forging heating temperature is set to 1145°C, and the temperature is kept for 20-40 minutes. The mold is designed according to the center difference of the forging. After the 2mm thick touch plate is placed on the lower mold cavity, the forging hammer is used for 2-3 blow forging;

[0033] After forging, the surface of the forging is cleaned. First, the blade is shot blasted with 1.2mm diameter alloy steel shots, and then the defect parts of the blade are polished. It is required to remove all defects such as edges, folds, and burrs.

[0034] After polishing, thermal shaping is carried out. The thermal shaping temperature is 1145°C, and the holding time is 10-20 minutes (half of the original time). During the thermal shaping, the 2mm thick contact plate is removed, and one-shot molding is performed.

[0035] After the hot shaping, the blades are shot blasted again with alloy steel shots. Afte...

Embodiment 3

[0038] Process a long blade whose length L is 1400mm, its structure see Figure 4 , Figure 4 Middle B is the air inlet side of the blade; the forging heating temperature is set to 1135°C, and the temperature is kept for 40-80 minutes. The mold is designed according to the center difference of the forging. strike forging;

[0039] After forging, the surface of the forging is cleaned. First, the blade is shot blasted with 1.2mm diameter alloy steel shots, and then the defect parts of the blade are polished. It is required to remove all defects such as edges, folds, and burrs.

[0040] After polishing, thermal shaping is carried out. The thermal shaping temperature is 1135°C, and the holding time is 20-40 minutes (half of the original time). During the thermal shaping, the 2mm thick contact plate is removed, and one-shot molding is performed.

[0041] After the hot shaping, the blades are shot blasted again with alloy steel shots. After the shot blasting, visual inspection is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com