Method for controlling refrigerator

A control method and refrigerator technology, which is applied to household refrigerators, machine operation methods, refrigerators, etc., and can solve problems such as failure to disclose water vapor, inability to directly apply defrosting operation control logic, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

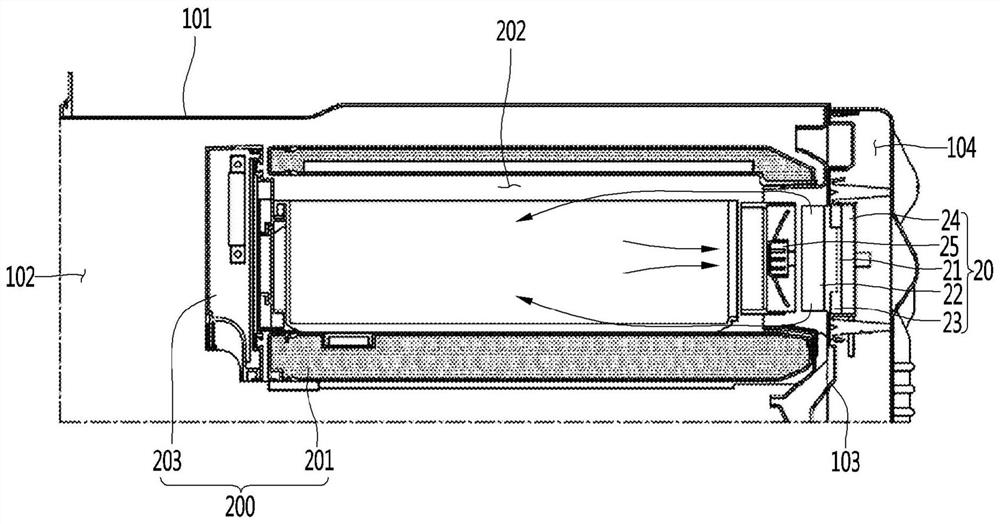

[0537] The first embodiment of the defrosting operation of the deep freeze chamber of the present invention has been described above, that is, the method of performing the defrosting operation of the cold-side radiator first, and then performing the defrosting operation of the hot-side radiator.

[0538] The deep freeze chamber defrosting operation method according to the second embodiment of the present invention is characterized in that the defrosting of the radiator on the hot side is performed preferentially, and the radiator defrosting operation on the cold side is performed thereafter.

[0539] In detail, according to the second embodiment in which the hot-side radiator defrosting operation is performed first, there is no need to provide a rest period in which power supply to the thermoelectric element is interrupted before the hot-side radiator defrosting operation is started.

[0540] This is because, since the forward voltage is supplied to the thermoelectric element b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com