Anti-overflow type carbonated beverage bottle

A carbonated beverage and anti-spill technology, applied to bottles, bottle/can parts, rigid containers, etc., can solve problems such as liquid ejection in beverage bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

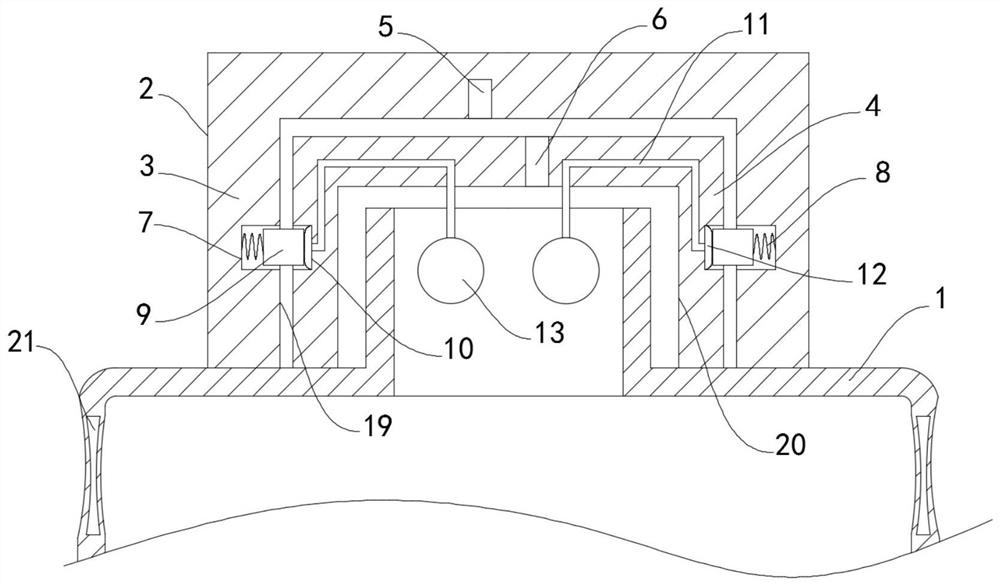

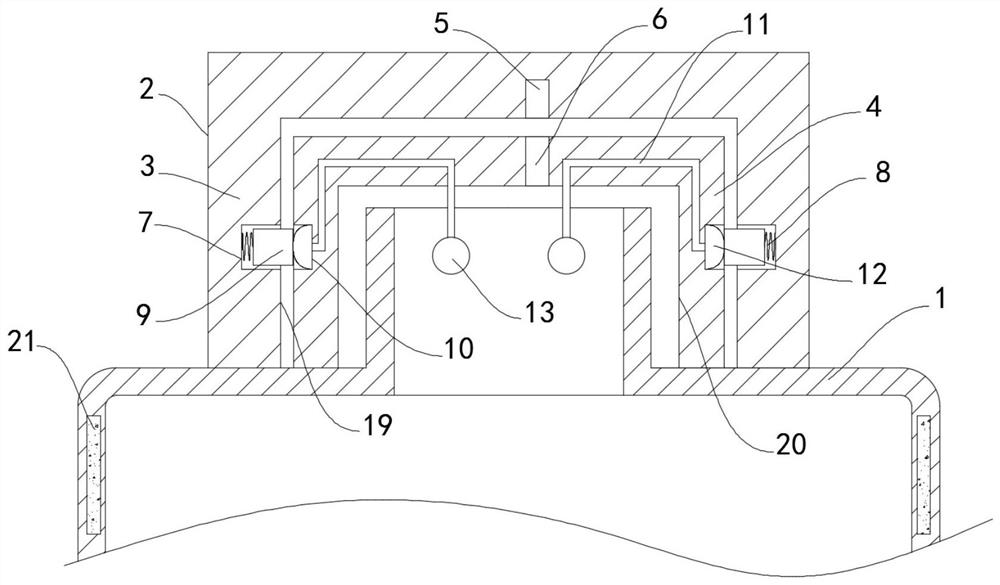

[0025] Such as Figure 1-2 As shown, a spill-proof carbonated beverage bottle comprises a bottle body 1, the bottle body 1 is provided with a bottle cap 2, the side wall of the bottle body 1 is provided with an annular liquid storage chamber 21, and the bottle cap 2 is composed of an outer shell 3 and an inner The outer shell 3 and the inner shell 4 are respectively provided with a placement groove 19 and a groove 20, the outer shell 3 and the inner shell 4 are rotatably connected, and the surfaces of the outer shell 3 and the inner shell 4 are respectively provided with a first through hole 5 and a second through hole. The through hole 6, the first through hole 5 is in sealing communication with the liquid storage chamber 21, by setting the first through hole 5 and the second through hole 6, when the air pressure in the bottle body 1 increases, the beverage is introduced into the liquid storage chamber 21, To avoid the direct spraying of beverages, resulting in waste, the fir...

Embodiment 2

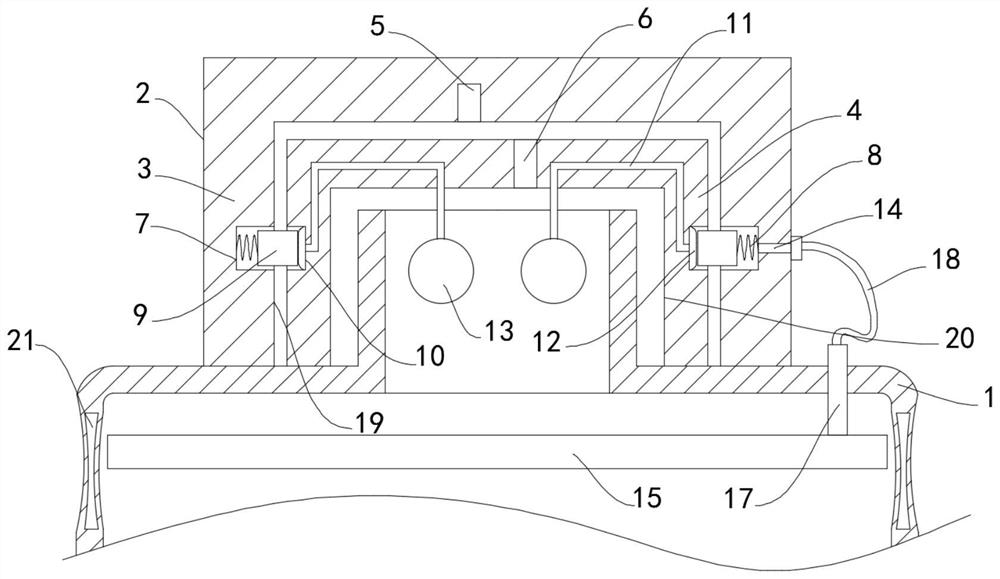

[0031] Such as Figure 3-5 As shown, the difference between this embodiment and Embodiment 1 is that the slider 9 is sealed and slidably connected in the sliding groove 7, the limiting groove 10 extends outwards with an exhaust hole 14, and the surface of the bottle body 1 penetrates and is fixedly connected with a The connecting pipe 17, the upper end of the connecting pipe 17 extends to the outside of the bottle body 1, the connecting pipe 17 is sealed and fixedly communicated with the exhaust hole 14 through the rubber tube 18, and the lower end of the connecting pipe 17 is sealed and fixedly communicated with a ring 15, it is worth noting that, The ring 15 is made of a hard material, and the hard material is hard rubber. The inner wall of the ring 15 is sealed and fixedly communicated with a plurality of hoses 16. It should be noted that the hoses 16 are made of a high-elastic material. The material is natural rubber. By setting the rubber tube 18, when the slider 9 slides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com