Technological method for prolonging storage period of automatically-formed core material

A process method and automatic molding technology, applied in the field of composite material manufacturing, can solve the problems of poor molding quality, low production efficiency, and short timeliness, and achieve the effects of mass production, quality assurance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

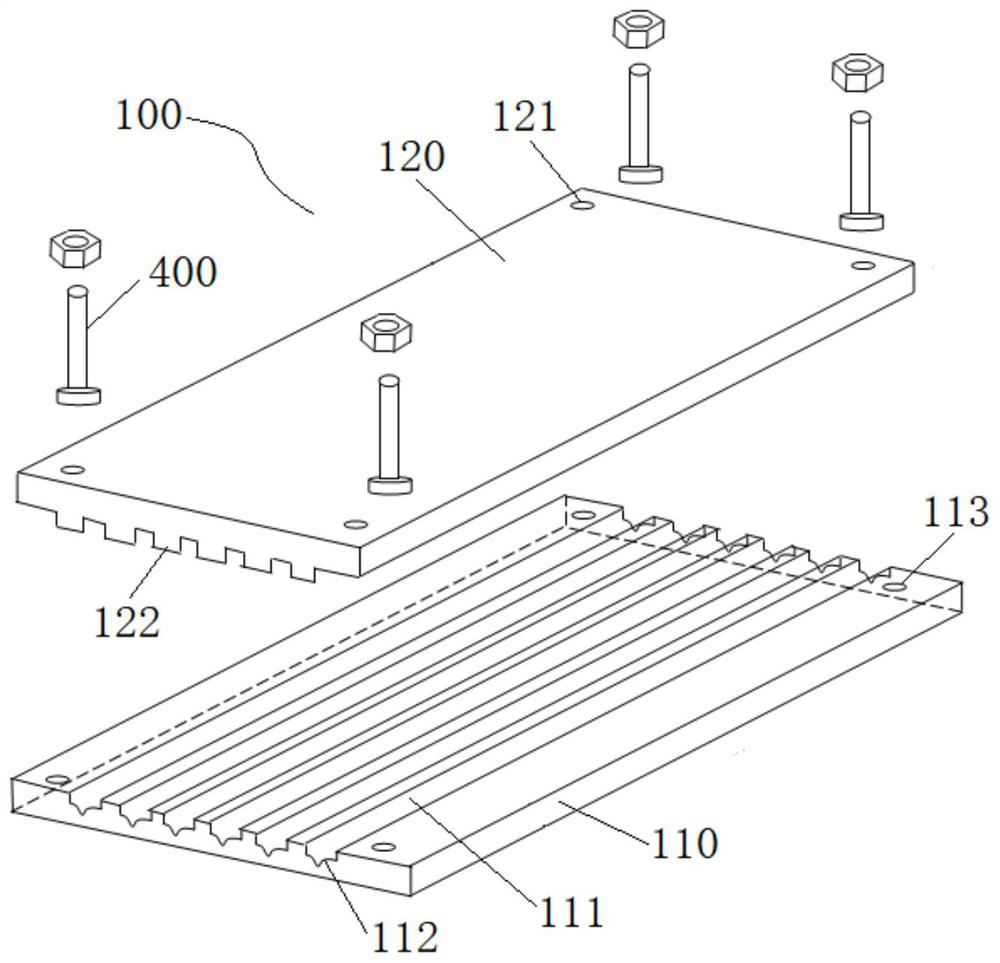

[0036] Such as Figure 1-4 As shown, the present embodiment provides a process method for prolonging the storage period of the automatic forming core material, comprising the following steps:

[0037] Step S1: making a core material storage mold 100;

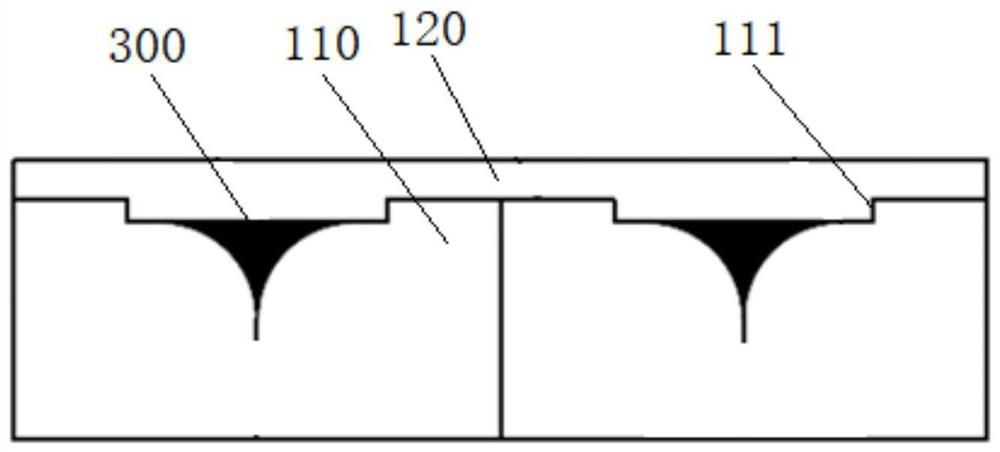

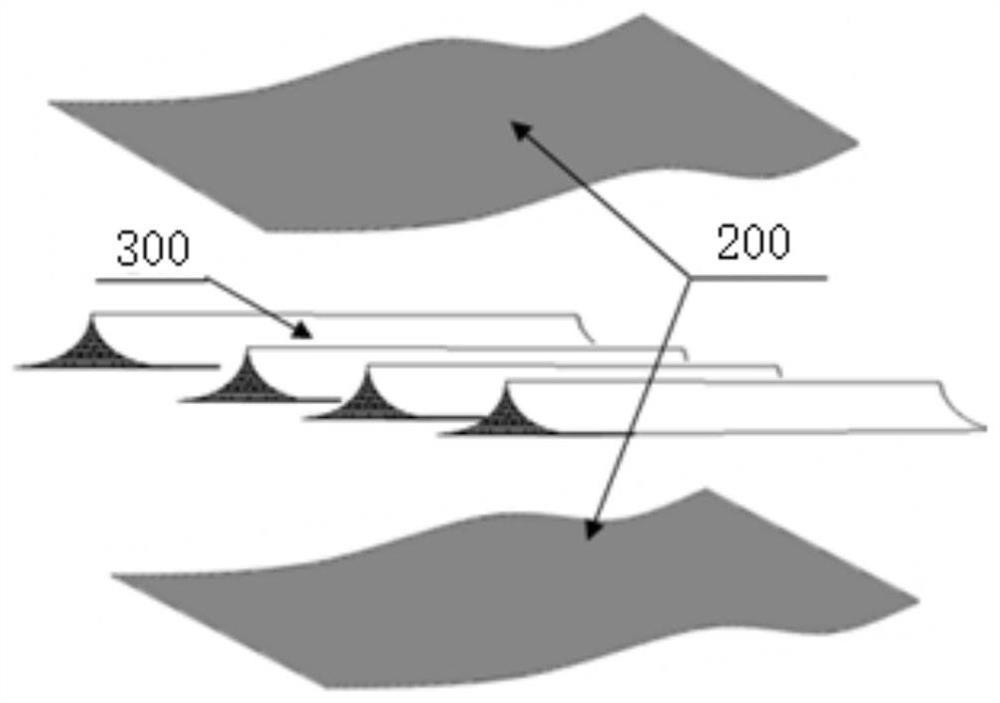

[0038] Step S2: Cover, wrap and seal the filling core material 300 with the isolation film 200, put the sealed filling core material 300 into the core material storage mold 100, and then carry out compaction treatment;

[0039] Step S3: Put the core material storage mold 100 and the filling core material 300 inside as a whole into the freezer for storage.

[0040] In this embodiment, the filling core material 300 is temporarily stored by making a dedicated core material storage mold 100, which can meet the requirements of mass production. Since the filling core material 300 is a carbon fiber prepreg material, it is taken out of the freezer and placed at room temperature. The service life of the external storage is calculated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com