Cutting machine for aluminum foil adhesive tape

A technology of aluminum foil tape and dividing machine, which is applied in the directions of sending objects, processing of thin materials, transportation and packaging, etc., can solve the problems of thickness and deformation of the rubber tube, affecting the appearance and normal use of the tape, and achieve the effect of preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

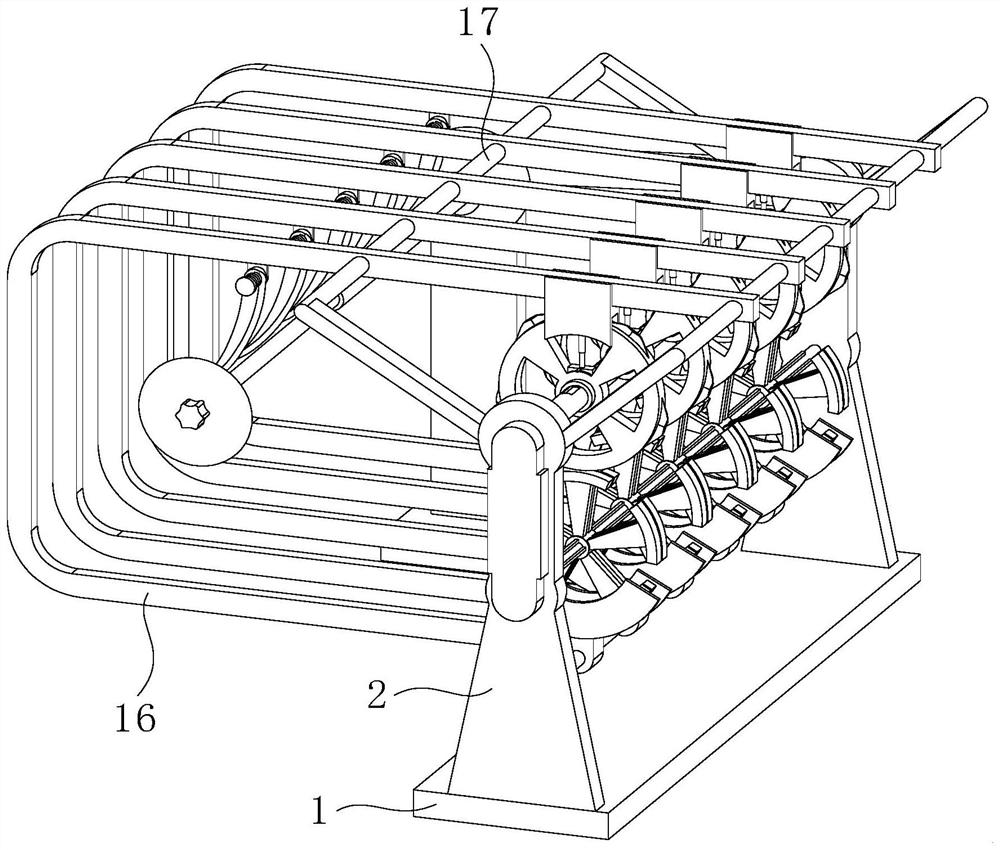

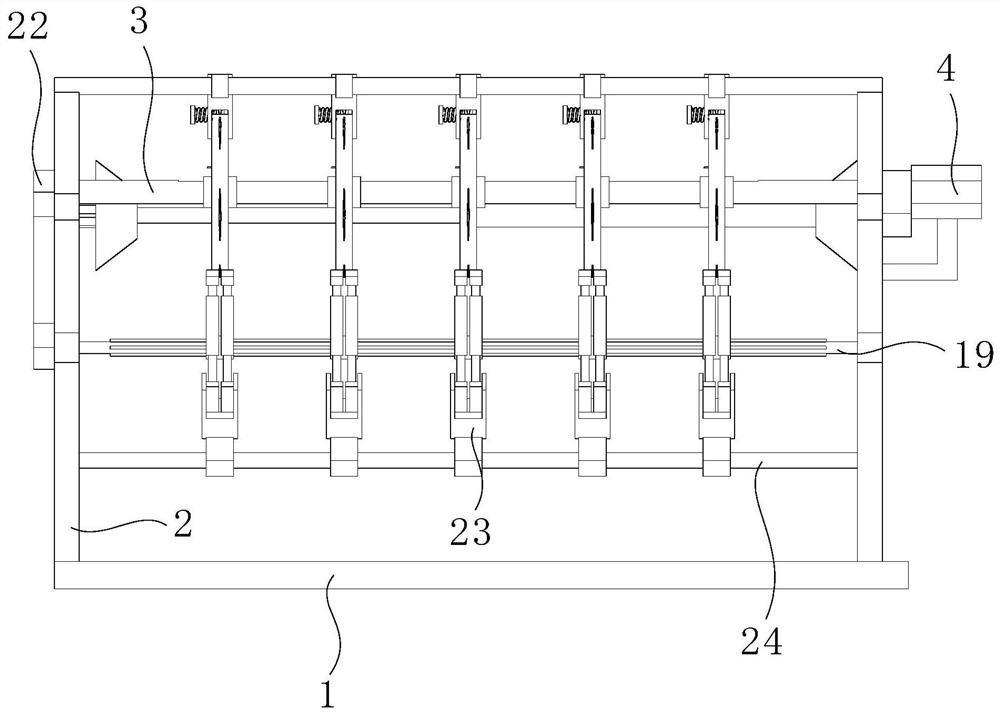

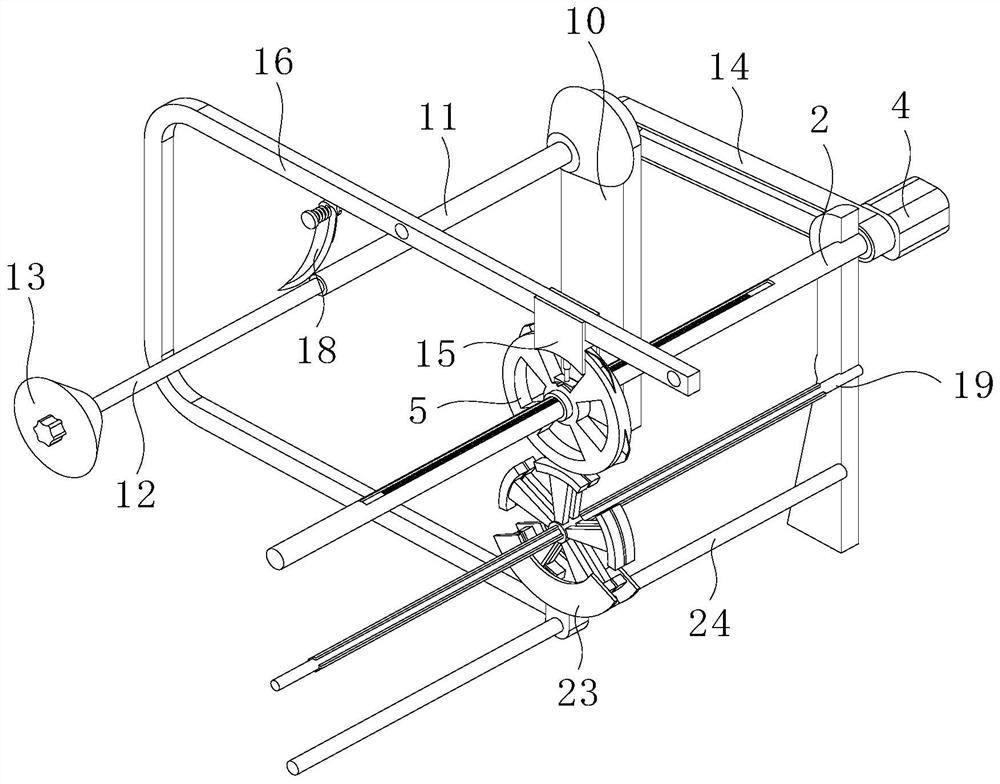

[0022] Such as Figure 1-6 As shown, a dividing machine for aluminum foil tape includes a bottom plate 1 and a fixed plate 2, the number of the fixed plates 2 is two, the bottom surfaces of the two fixed plates 2 are fixedly connected with the upper surface of the bottom plate 1, and the top of the bottom plate 1 is set There is a driving shaft 3, the two ends of the driving shaft 3 respectively rotate through the upper ends of the two fixing plates 2, the back of the fixing plate 2 at the rear is fixedly connected with a motor 4, the output end of the motor 4 is fixedly connected with the back of the driving shaft 3, One end of the drive shaft 3 located between the two fixed plates 2 is slidably sleeved with a plurality of runners 5 , and five segment pieces 6 are fixedly connected to the circumferential side of the runners 5 .

[0023] The inside of runner 5 is positioned at the top of driving shaft 3 and is provided with spring telescopic rod 7, and the upper end of spring ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap