Prefabricated bridge deck formwork-free cast-in-place wet joint structure

A prefabricated panel and wet joint technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of poor quality controllability, large formwork workload, hidden safety hazards under bridges, etc., to ensure installation accuracy and reduce Construction costs and the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

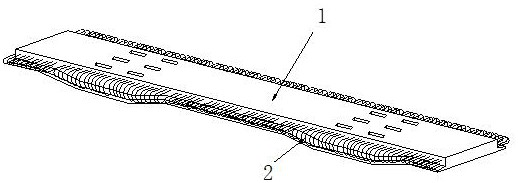

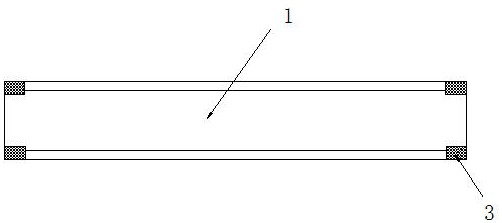

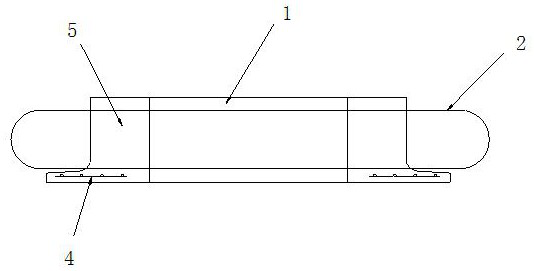

[0022] see Figure 1-Figure 5 , the specific embodiments of the present invention are as follows: a prefabricated bridge deck cast-in-place wet joint structure without formwork, its structure includes a plurality of prefabricated slabs 1 arranged along the bridge direction, and two adjacent prefabricated slabs 1 are continuously laid The cast-in-place section 8 between the slabs 1, the prefabricated slab 1 is provided with a half "U"-shaped structure extension 5 along the bridge to both ends, and the half "U"-shaped structure of two adjacent prefabricated slabs The extension section is butted to form a whole "U" shape. The notch 6 is used as the bottom form of the cast-in-place section 8, which saves a large amount of formwork engineering work on site, and effectively controls the construction process quality of the wet joint structure to ensure the structure Stress continuity at wet joints; the cast-in-place section 8 is poured and connected with two adjacent prefabricated sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com