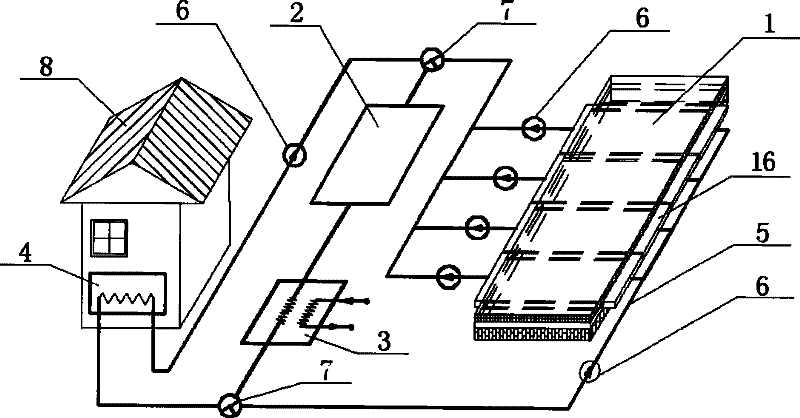

Porous thermal conductive asphalt concrete pavement heat exchange system and use thereof

An asphalt concrete, heat exchange system technology, applied in applications, air conditioning systems, indirect heat exchangers, etc., can solve problems affecting road quality, durability and service life, prone to rutting, wave passing, etc., to reduce road maintenance. cost, extended service life, reduced low temperature cracks and high temperature deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1、 example 2 and example 3

[0048] The percentage by weight of the composition of common asphalt concrete among the example 1 is: coarse aggregate 54%, fine aggregate 26%, asphalt 6.5%, graphite powder 0%, slag powder 13.5%.

example 2

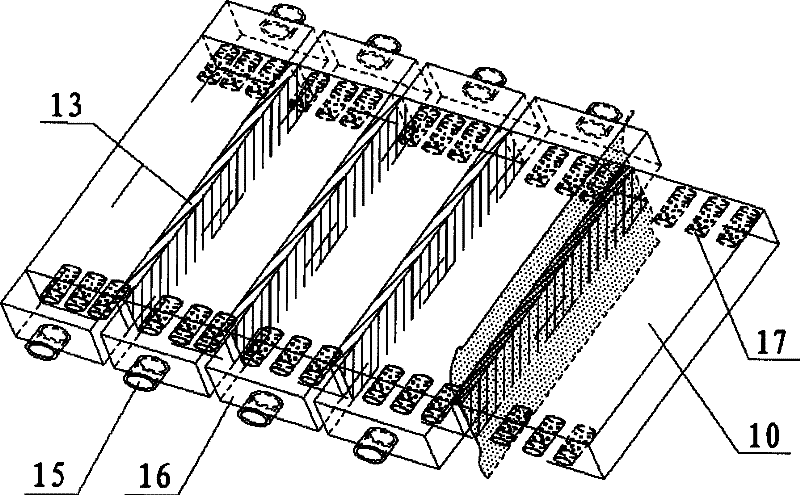

[0049] In Example 2, the composition weight percent of heat-conducting asphalt concrete is: coarse aggregate 54%, fine aggregate 26%, asphalt 6.5%, graphite powder 11%, mineral powder 2.5%.

example 3

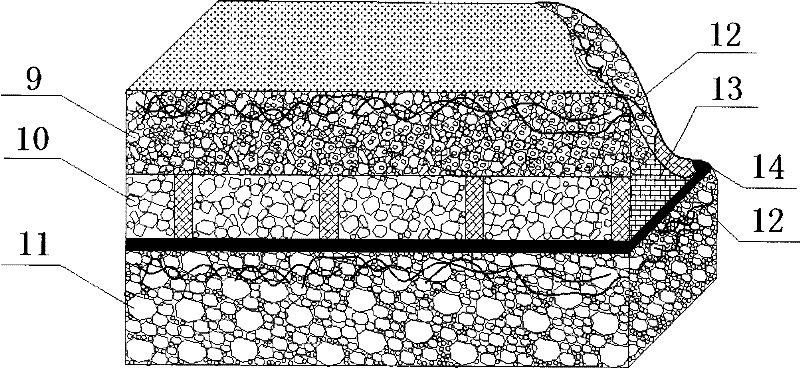

[0050] The composition weight percent of porous heat-conducting bituminous concrete in the example 3 is: coarse aggregate 62%, fine aggregate 19%, asphalt 4.5%, graphite powder 11%, slag powder 2.5%, TPS modifier 1.5%, polyester fiber 0.3% %. Its related performance indicators are shown in Table 1. It can be seen from Table 1 that after adding graphite powder, the thermal conductivity of porous asphalt concrete increases from 1.52W / m·K to 2.69W / m·K; other properties meet the requirements of design specifications.

[0051] According to the ratio of Example 1, the upper layer and the lower layer were generated, and the ratio of Example 3 was used to generate the middle layer for combined rutting. The test showed that the dynamic stability was 4152 times / mm, and the overall rut depth was 4.73mm. After cutting the rutting plate from the test site, it was found that the contribution of the porous middle surface to the rutting depth was 2.81 mm, but it still met the design requirem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com