An assembly system that facilitates the installation and removal of brake discs

A technology for assembling systems and brake discs, which is used in metal processing equipment, metal processing, manufacturing tools, etc., to achieve the effects of low installation cost, increased contact area, and avoidance of frequent replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

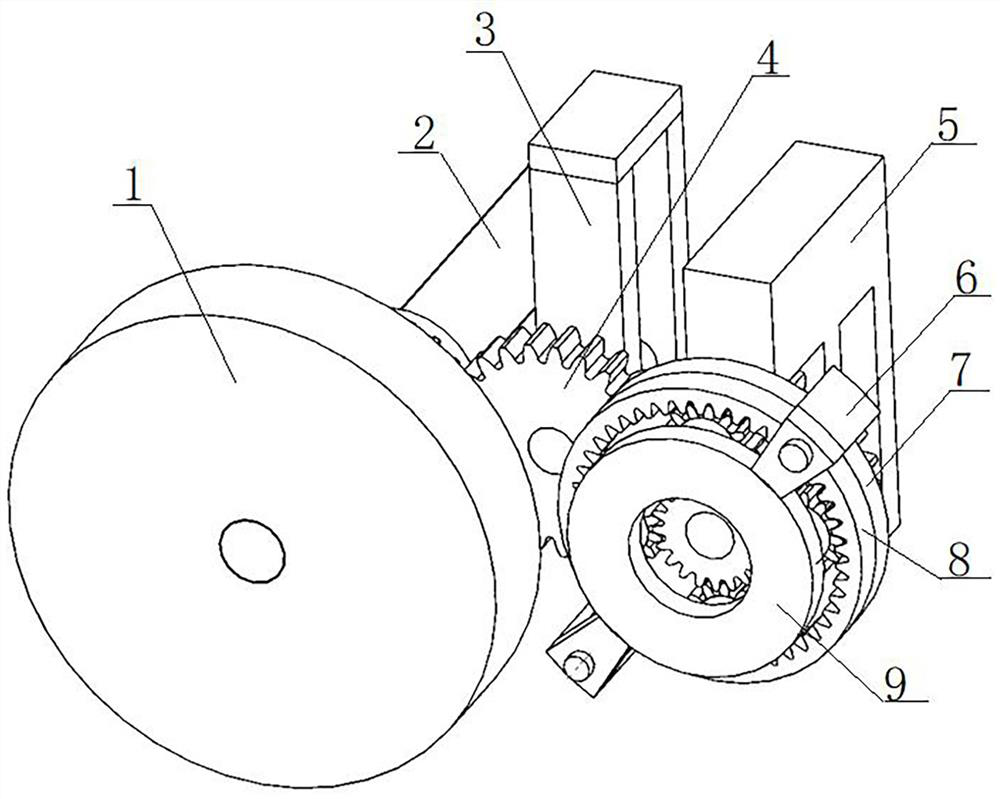

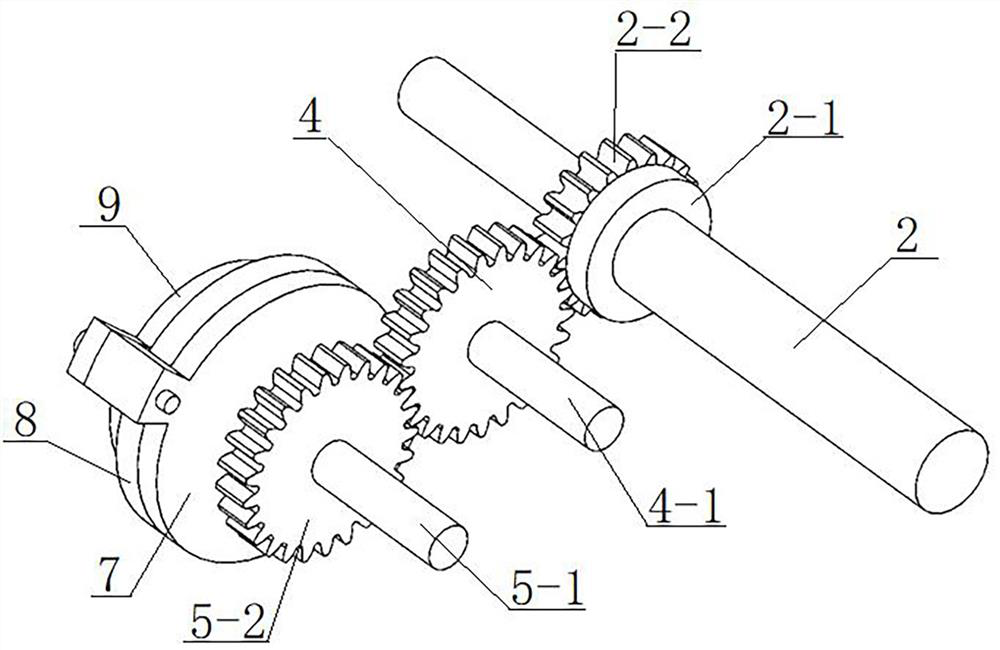

[0032] see figure 1 , an assembly system for easy installation and disassembly of brake discs, including an output shaft 2 arranged under the vehicle body, a brake caliper 9 and an oil pipe system, and a fixed plate 2-1 arranged on the output shaft 2, sleeved on the output The driving gear 2-2 connected to the fixed plate 2-1 on the shaft 2, the intermediate gear 4 meshed with the outside of the driving gear 2-2, the intermediate shaft 4-1 passing through the intermediate gear 4 is connected with the support one 3, and the support -3 is arranged at the bottom of the car body;

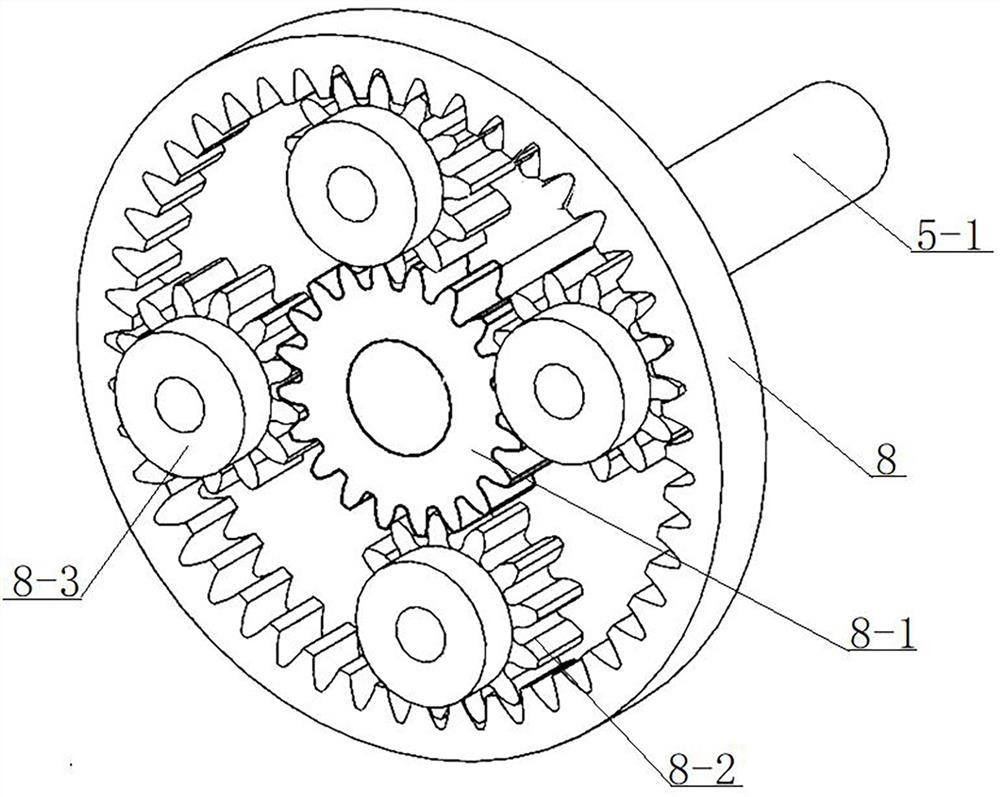

[0033] The intermediate gear 4 is connected with the driven system. The driven system is provided with a brake disc 8-3 and a brake caliper 9 which is in detachable contact with the brake disc 8-3. The brake caliper 9 is also connected with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com