Magnetron sputtering coating device and working method thereof

A magnetron sputtering coating and magnetron sputtering technology, applied in the field of vacuum sputtering, can solve problems such as different distances, inconsistent coating thickness, inconsistent color and optical properties of end products, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

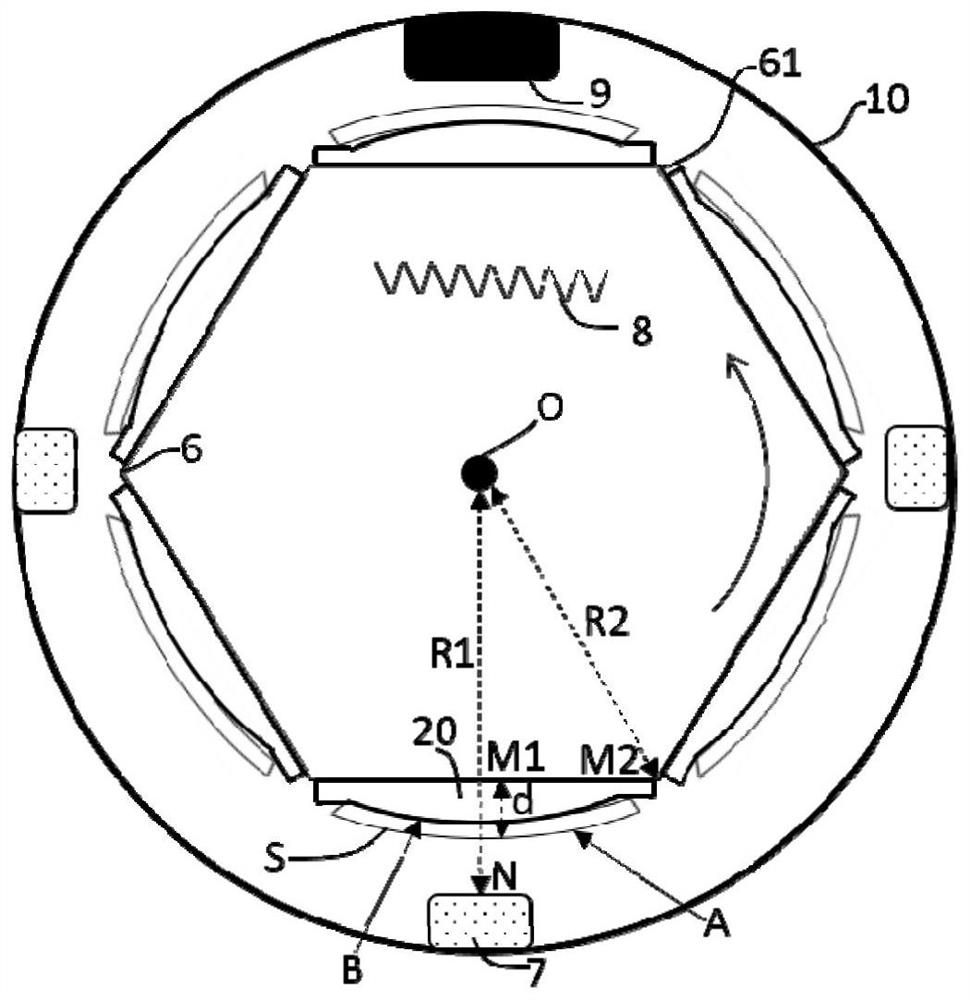

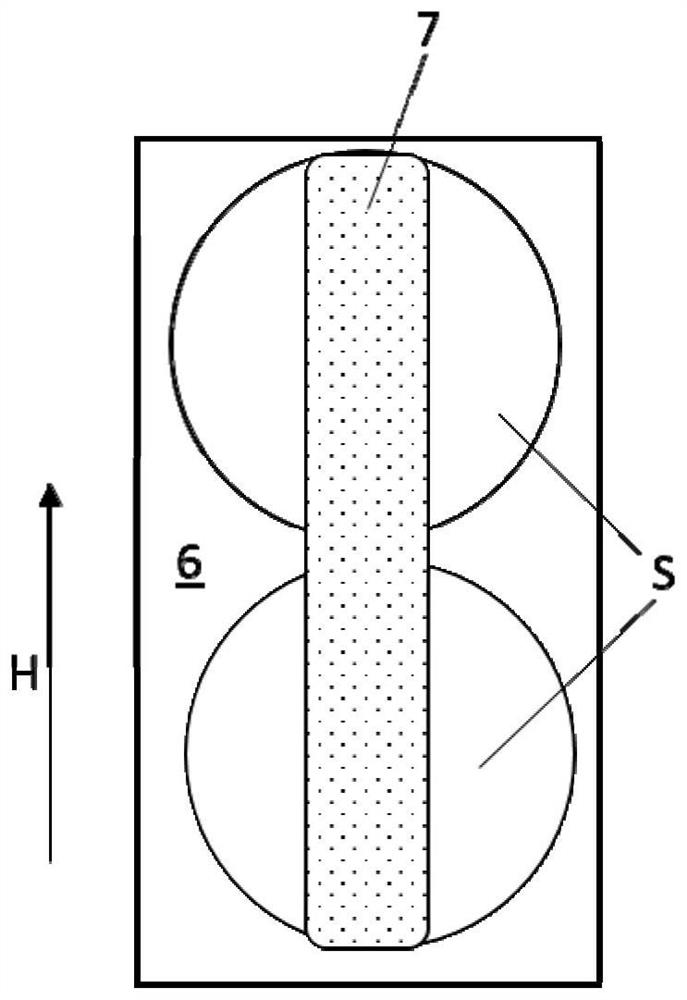

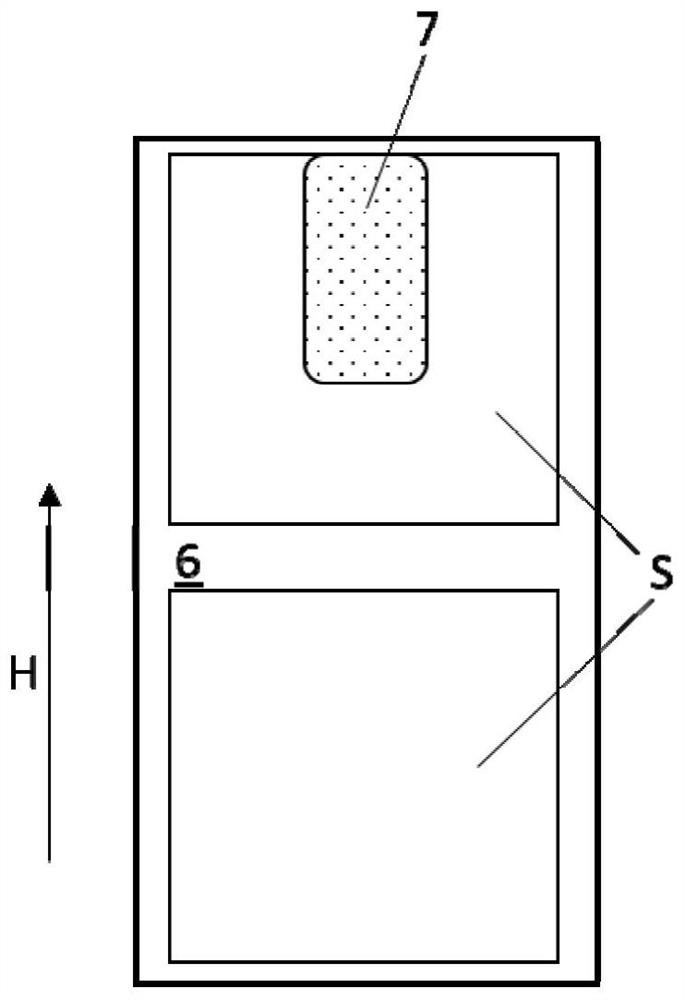

[0033] The present invention provides a magnetron sputtering coating device, comprising: a vacuum coating chamber; a rotatable work frame, which can rotate in the vacuum coating chamber along its central Coating workpiece, the workpiece to be coated has a surface to be coated, and the surface to be coated protrudes in a direction away from the central axis; at least one magnetron sputtering source is arranged in the vacuum coating chamber for spraying the workpiece to be coated sputter coating material particles on the surface of the magnetron sputtering source, and there is a gap between the magnetron sputtering source and the surface to be coated. The uniformity of the coating film prepared by using the magnetron sputtering coating device is good.

[0034] In order to make the above objects, features and beneficial effects of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com