Tubular large-volume plasma polymerized coating device

A plasma and coating device technology, applied in the field of plasma, can solve the problems of poor batch processing uniformity, small batch, high cost, etc., and achieve the effect of large batch processing, low cost, and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

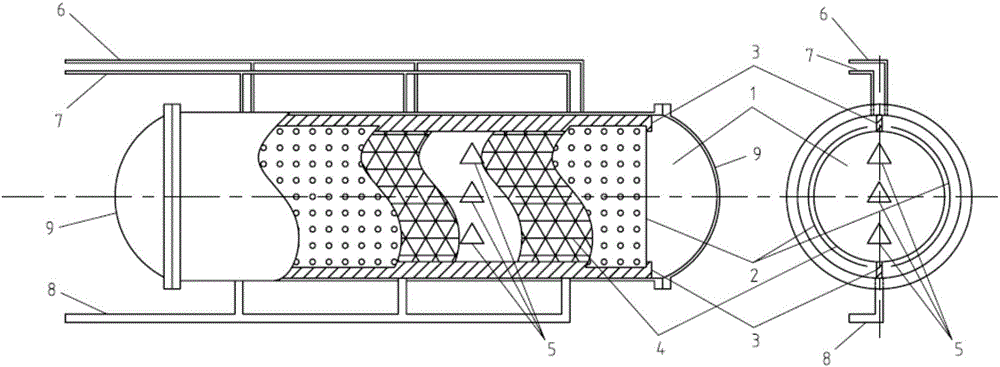

[0019] Such as figure 1 Shown, a kind of tubular large-volume plasma polymerization coating device, vacuum chamber 1 is tubular, and the inner diameter of vacuum chamber 1 is 30cm, and length is 10m, and electrode 2 and guide rail 3 are installed on the inner wall of vacuum chamber 1, described The gap between the electrode 2 and the inner wall of the vacuum chamber 1 is 10 mm. The electrode 2 is cylindrical and located on the cylindrical surface coaxial with the vacuum chamber 1. The electrode 2 is divided into left and right parts, leaving a gap in the middle to install the guide rail 3 , the electrode 2 is not in contact with the guide rail 3, the electrode is covered with through holes, the aperture is 2mm, the hole interval is 2mm, the material of the electrode is aluminum or stainless steel; the jig 4 is installed on the guide rail 3, and the vacuum chamber 1 Shaft, the base material 5 to be treated is installed in the jig 4, the jig 4 is a cylindrical cage made of metal...

Embodiment 2

[0021] A tubular large-volume plasma polymerization coating device, the vacuum chamber 1 is tubular, the inner diameter of the vacuum chamber 1 is 80cm, and the length is 0.5m. Electrodes 2 and guide rails 3 are installed on the inner wall of the vacuum chamber 1. The electrodes 2 The gap between it and the inner wall of the vacuum chamber 1 is 60mm, wherein the electrode 2 is cylindrical and is located on the cylindrical surface coaxial with the vacuum chamber 1. The electrode 2 is divided into three parts, and the gap left is installed with the guide rail 3. The electrode 2 and the The guide rail 3 is not in contact, the electrodes are covered with through holes, the aperture is 30 mm, the hole interval is 30 mm, and the material of the electrodes is aluminum or stainless steel; the jig 4 is installed on the guide rail 3, coaxial with the vacuum chamber 1, to be processed The base material 5 is installed in the jig 4, and the jig 4 is a cylindrical cage made of metal or plast...

Embodiment 3

[0023] A tubular large-volume plasma polymerization coating device, the vacuum chamber 1 is tubular, the inner diameter of the vacuum chamber 1 is 50cm, and the length is 5m. Electrodes 2 and guide rails 3 are installed on the inner wall of the vacuum chamber 1. The electrodes 2 and The gap between the inner walls of the vacuum chamber 1 is 30mm. The electrode 2 is cylindrical and located on the cylindrical surface coaxial with the vacuum chamber 1. The electrode 2 is divided into six parts, leaving a gap in the middle to install the guide rail 3. The electrode 2 and the The guide rail 3 is not in contact, the electrodes are covered with through holes, the aperture is 15 mm, the hole interval is 15 mm, and the material of the electrodes is aluminum or stainless steel; the jig 4 is installed on the guide rail 3, coaxial with the vacuum chamber 1, to be processed The base material 5 is installed in the jig 4, and the jig 4 is a cylindrical cage made of metal or plastic, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com