Progressive distributor for lubricant

A lubricant, progressive technology, applied in the field of progressive dispensers, can solve the problems of lubricant aging, hindered connection, lubrication system failure, etc., to achieve the effect of improving service life, improving accuracy, and improving transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

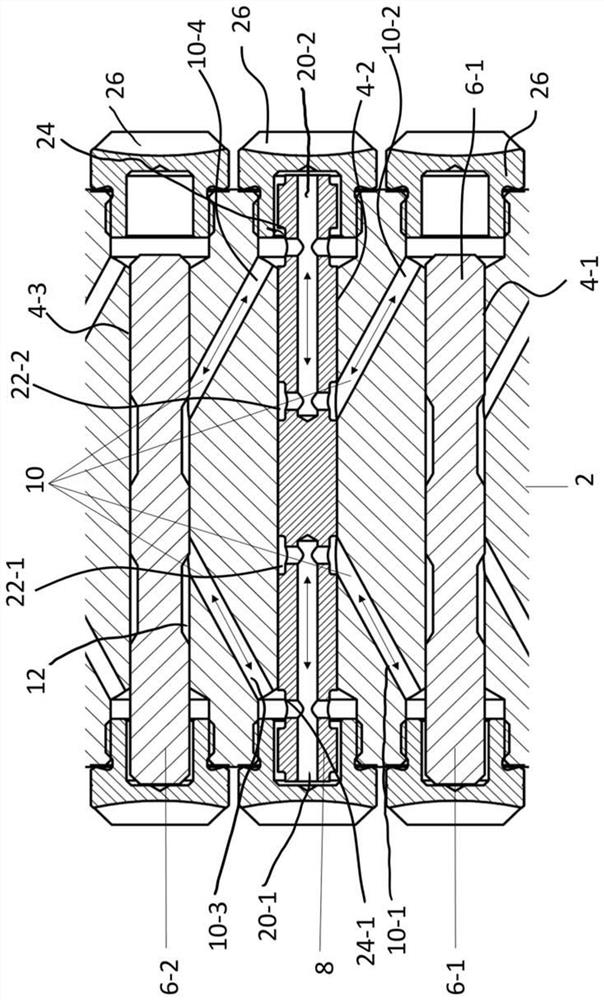

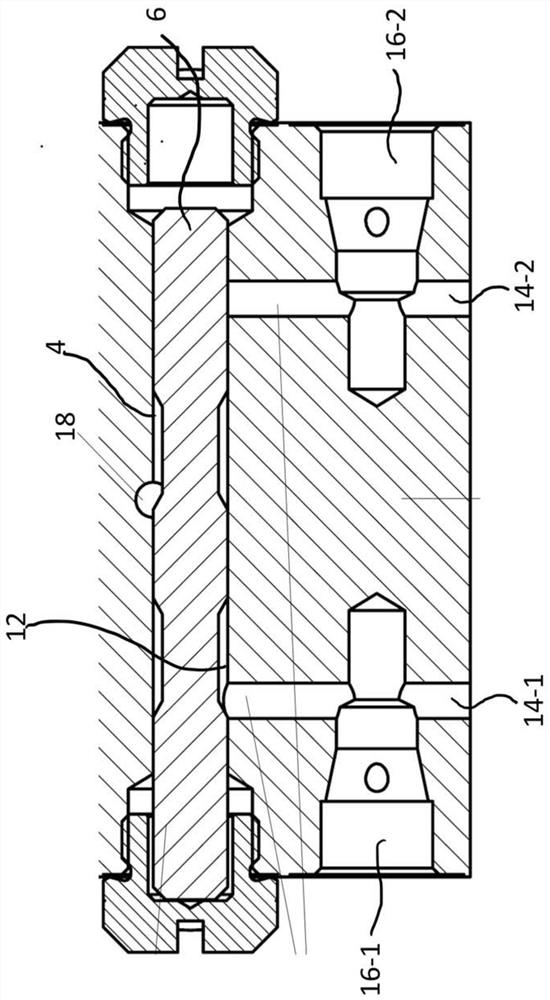

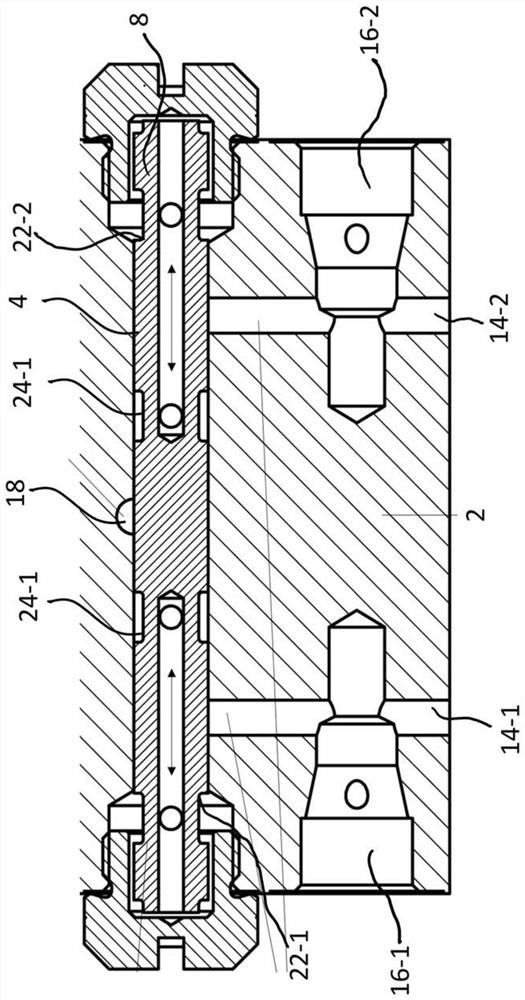

[0030] Figures 1 to 3 Various cross-sectional views through the components of the progressive dispenser 1 constructed in blocks are shown. To this end, the progressive distributor 1 generally comprises a housing block 2 into which a plurality of holes are introduced. From figure 1 , 2 3 and 3, it can be seen that the housing block 2 comprises a piston bore 4 in which a metering piston 6 or a balancing piston 8 can be accommodated.

[0031] From figure 1 It can also be seen that the piston bores 4 are connected to one another via connecting bores 10 . Lubricant passes from one piston bore 4 to the other piston bore 4 or lubricant outlet ( figure 1 not shown). exist figure 2 and 3The lubricant outlet hole 14 and the associated lubricant outlet 16 are shown in the sectional view of FIG. here, figure 2 is a sectional view through the lubricant outlet associated with the metering piston 6, while image 3 A sectional view through the lubricant outlet associated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com