Bubble water machine

A technology of bubble water machine and casing, which is applied in the direction of mixer, water/sewage treatment of added substances, mixing method, etc., and can solve the problem of not being able to make cold drink soda

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

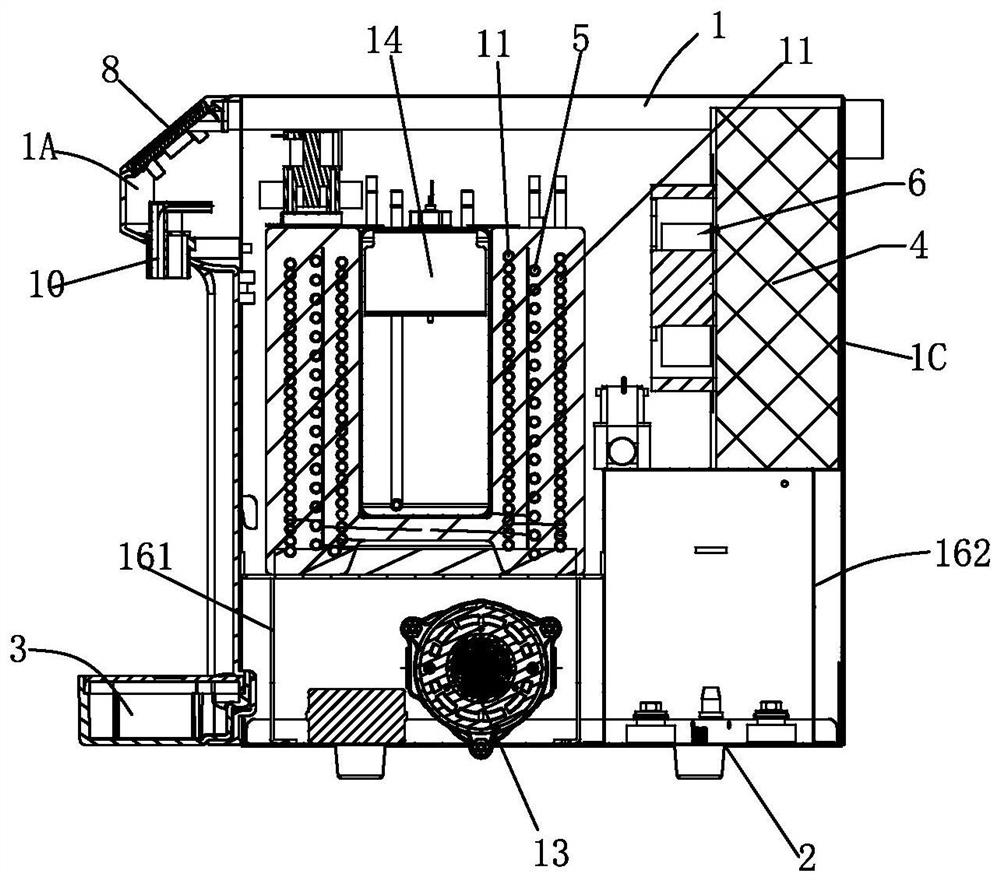

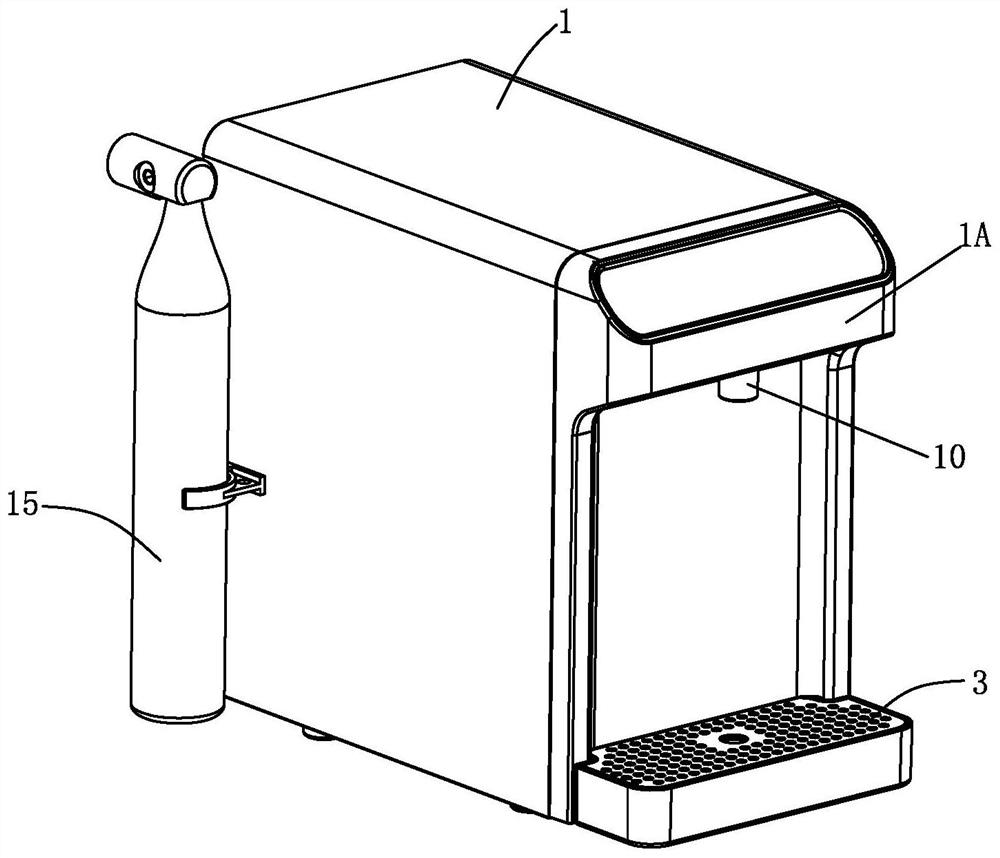

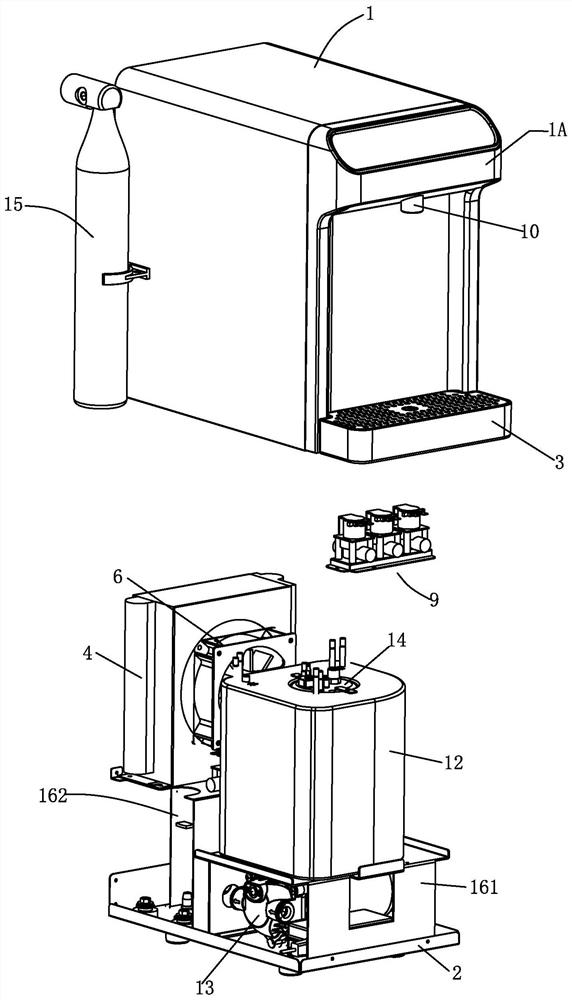

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] Such as figure 1 As shown, a bubble water machine includes a casing 1, a base 2, a water receiving tray 3 located at the front lower part of the casing, a compressor, a condenser 4, an evaporator 5, a cooling fan 6, a temperature controller 7 and an operating The circuit board 8 and the base 2 are embedded in the lower end of the casing 1, and the casing 1 and the base 2 are fixedly connected; the cooling fan 6 is opposite to the condenser 4;

[0033] The front upper part of the casing 1 extends forward to form a control chamber 1A, the side wall of the casing is provided with an air inlet 1B, and the rear wall is provided with an air outlet 1C;

[0034] The evaporator 5 includes a cylindrical body with upper and lower openings made of wound tubes, a refrigerant inlet pipe and a refrigerant outlet pipe,

[0035] It also includes a water inlet solenoid valve (n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com