Method for tensioning safety rope on steel beam

A safety rope and tensioning technology is applied in the field of tensioning safety ropes on steel beams, which can solve the problems of inconvenient installation and disassembly, damage to the main structure of steel beams, and unreusable safety rope pillars, etc. Improve the overall structural stability and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

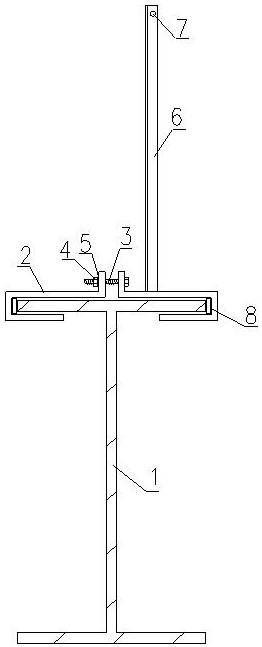

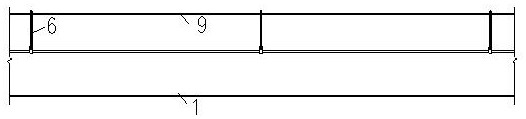

[0027] The specific embodiment, the inner side of the vertical bar of the clip 1 is respectively fixed with rubber pads 8, which are used to prevent the main body of the steel beam 1 from being damaged by the contact between the clip 2 and the upper flange of the steel beam 1 during the tightening of the fastening nut 4 .

[0028] Here the rubber pads are fixed on the inner sides of the corresponding vertical rods by adhesive. In this way, a rubber pad is provided at the contact between the clip and the upper flange of the steel beam, so when the nut is tightened, the clip will not directly contact the main body of the steel beam, so it will not cause damage to the main structure of the steel beam; at the same time, due to the rubber pad The setting of the block can make after the fastening nut is tightened, the clip and the upper flange of the steel beam are buckled more closely, so that the overall structural stability of the safety rope tensioning measure frame is better. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com