Visual inspection system for tube-type bottle machine

A technology of machine vision inspection and visual inspection, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of high cost, inability to meet the comprehensive inspection of control bottles, and inability to detect appearance, etc., and achieve good detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

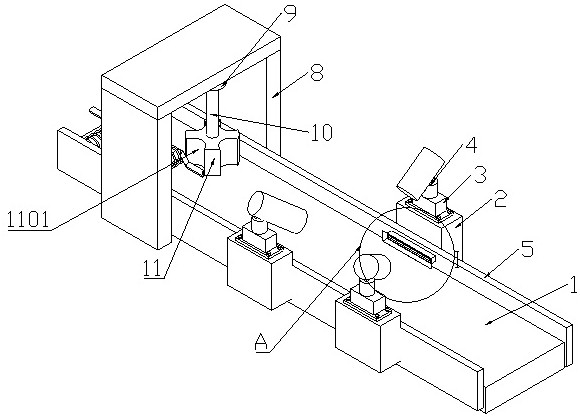

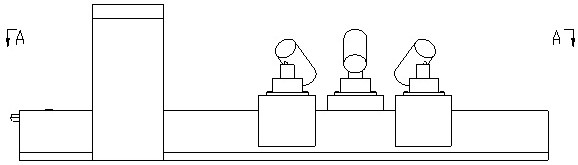

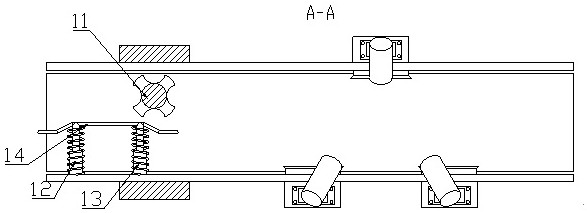

[0023] Such as Figure 1 to Figure 4 As shown, a control bottle machine vision inspection system provided by the present invention includes a conveyor belt 1, a visual detection component for inspecting the control bottle and a separation component for transporting the control bottle. 1 the baffles 5 on both sides, the fixing seat 2 arranged on the outer surface of the baffle 5, the supporting seat 3 arranged on the upper surface of the fixing seat 2 and the camera 4 arranged on the upper surface of the supporting seat 3, the said baffle 5 and the fixed The base 2 is fixedly connected, the fixed base 2 is fixedly connected with the support base 3 , and the camera 4 is fixedly connected with the support base 3 . By arranging the conveyor belt 1 , the fixing seat 2 , the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com