An inspection device with curved surface scanning function

A curved surface and functional technology, which is applied in the field of inspection devices with curved surface scanning functions, can solve the problems of not being able to provide different viewing angles of detection, increasing maintenance costs, and not being able to meet the requirements of online measurement with temporal and spatial resolution, so as to save instrument costs and installation costs, favorable maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

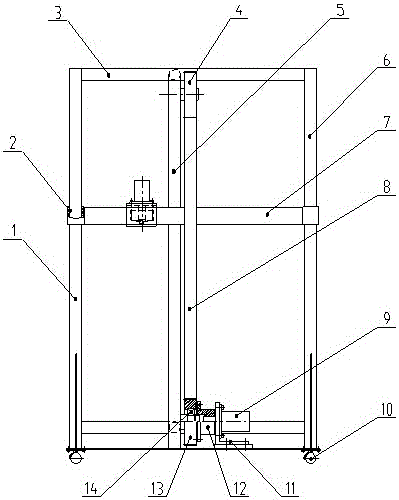

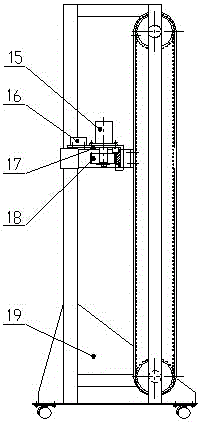

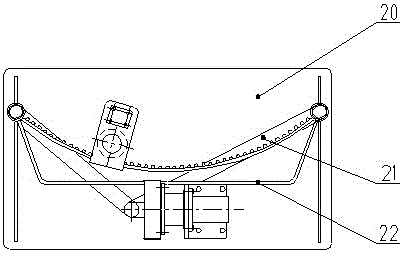

[0016] Such as figure 1 , figure 2 and image 3 As shown, the inspection device with curved surface scanning function of the present invention includes a curved surface frame, a lifting mechanism, a plane curve moving mechanism, and a detection device 16;

[0017] The curved surface frame comprises base plate 20, universal wheels 10, left guide rod 1, right guide rod 6, upper frame 3, lower frame 21, support rod 5; The left guide rod 1, the right guide rod 16, the motor bracket 11, and the support rod 5 are connected, and the upper frame 3 and the lower frame 21 are respectively connected with the left guide rod 1 and the right guide rod 6 to form a support body; The movement of the device back and forth, left and right provides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com