A method and system for controlling gas concentration in a high-gas coal mine mining face

A technology of mining working face and gas concentration, which is applied in the direction of gas discharge, pump control, mining equipment, etc., can solve the problems of low extraction efficiency of the gas drainage system and the inability to quickly reduce the gas concentration of the mining working face, and achieve rapid gas concentration The effect of reducing, saving electric energy and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

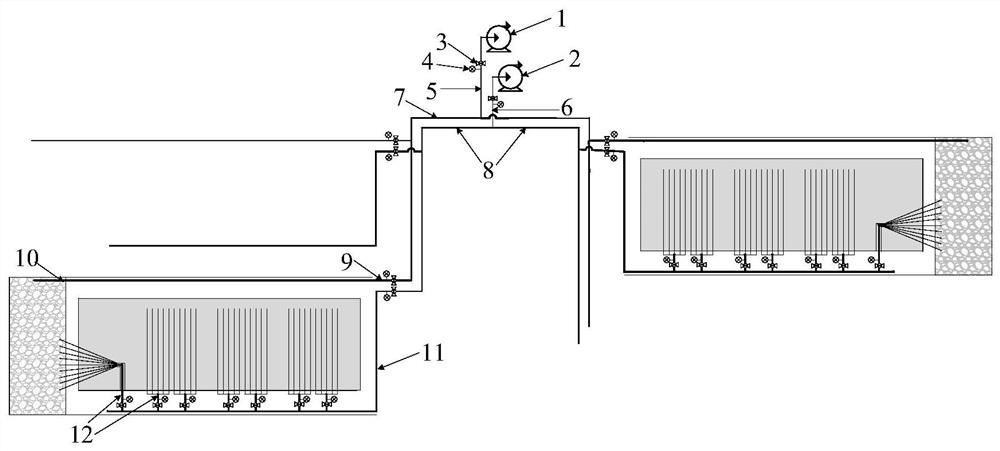

[0042] refer to figure 1 , which shows a schematic structural diagram of a gas concentration control system for a high-gas coal mining face in the present application, as shown in figure 1 As shown, the gas concentration control system in the mining face of high-gas coal mines includes: gas drainage pump station, high negative pressure gas drainage system, low negative pressure gas drainage system, data acquisition system 4, data processing system, intelligent control valve 3.

[0043] The gas drainage pumping station includes a high negative pressure gas drainage pump 2 and a low negative pressure gas drainage pump 1 .

[0044] The high negative pressure gas drainage system includes high negative pressure drainage main pipe 6, high negative pressure drainage main pipe 8, high negative pressure drainage branch pipe 11, high negative pressure drainage unit pipe 12, high negative pressure drainage unit pipe 12 Connecting multiple parallel drainage boreholes, the high negative ...

Embodiment 2

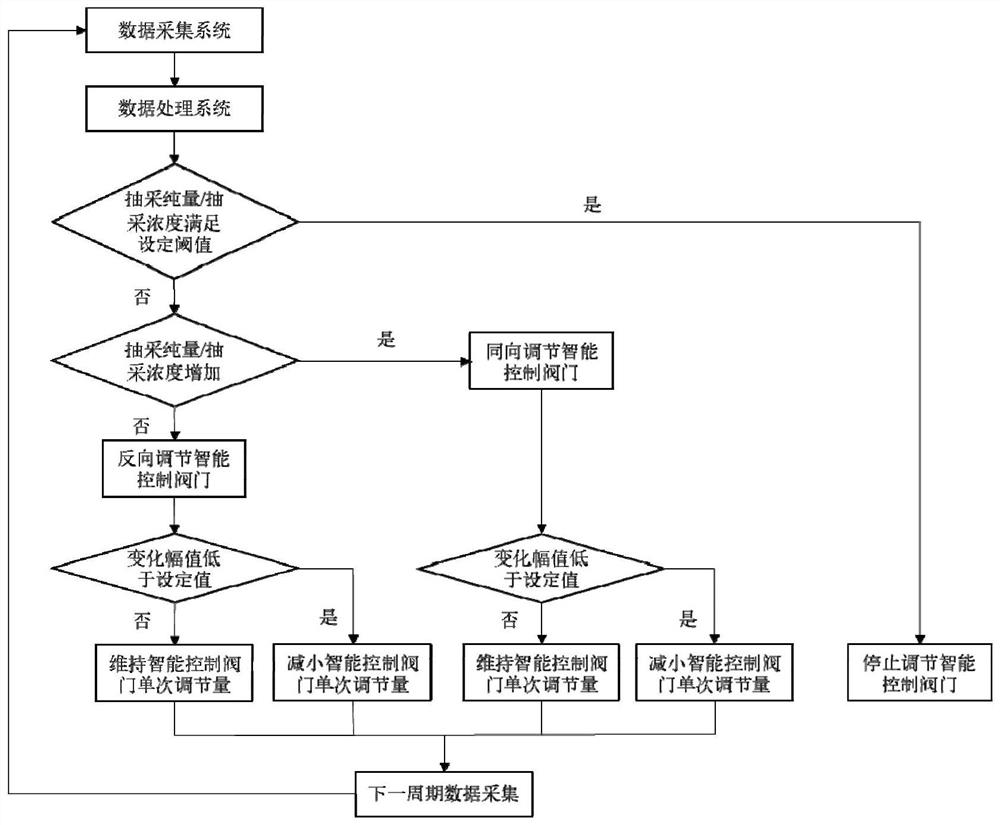

[0058] Based on the gas concentration control system in the working face of a high gassy coal mine provided in Embodiment 1 of the present application, another embodiment of the present application provides a method for controlling the gas concentration of a working face in a high gassy coal mine, including:

[0059] In the gas drainage pipeline, pipeline pressure is an important factor affecting the gas drainage effect. The relationship between the gas drainage flow rate of a certain section of the drainage pipeline and the pressure difference of the pipeline is shown in formula (1):

[0060]

[0061] In formula (1), Q 流 ΔP is the pressure difference at both ends of the pipeline; ρ is the gas fluid density; g is the acceleration of gravity; S is the frictional resistance of the pipeline; L is the length of the pipeline.

[0062] In addition, when the negative pressure value of the extraction branch pipe is determined, the orifice negative pressure of the extraction unit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com