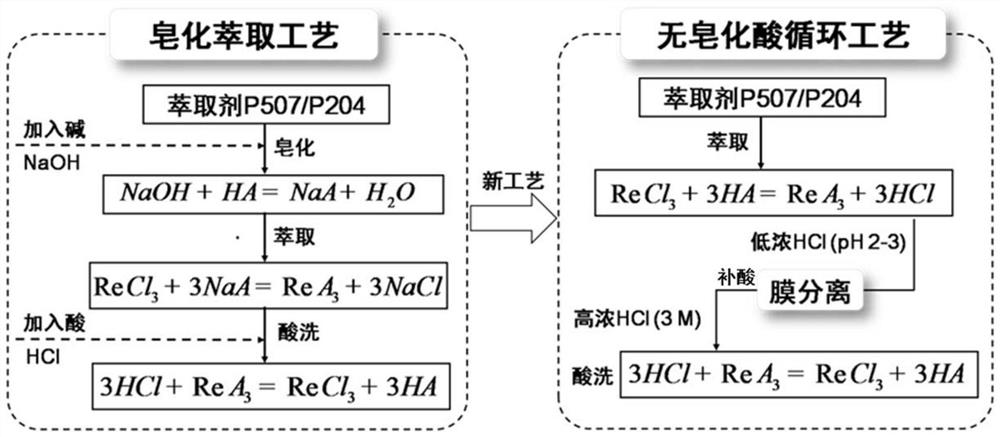

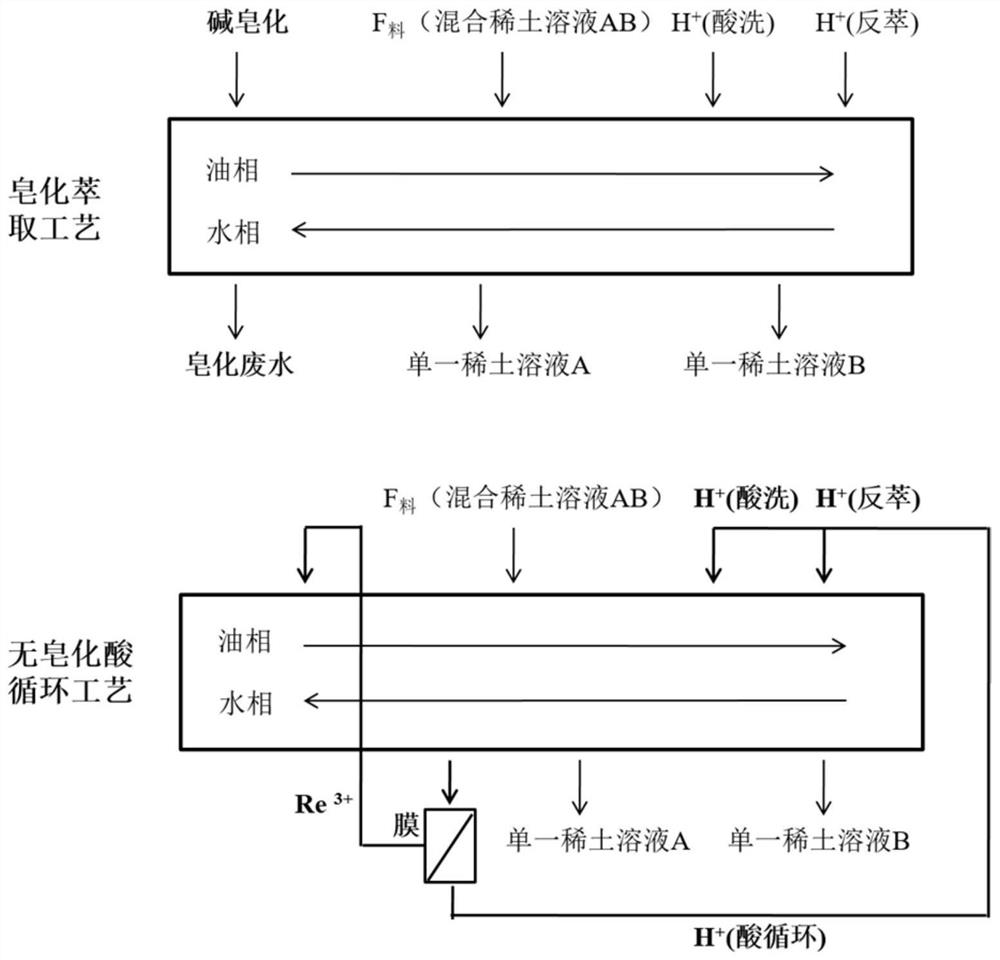

New membrane process reinforced saponification-free rare earth extraction and separation technology

A technology of rare earth extraction and separation without saponification, which is applied in the field of rare earth resource utilization and membrane separation, and can solve the problem of large amount of acid and alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Taking heavy rare earth as an example, add P507-200# kerosene extractant in the first stage of the extraction section, wherein the volume fraction of P507 is 40%, and the volume fraction of kerosene is 60%; add chlorinated rare earth material in the last stage of the extraction section Liquid (composition of liquid: YCl 3 1mol / L, HCl 0.5mol / L), water is added to the last stage of the stripping section and the washing section, and the extraction operation is carried out, wherein the ratio (O / A) of the extraction section is 1:1, and the two-phase residence time is 15min. The ratio (O / A) of the washing section is 2:1, and the two-phase residence time is 8 minutes. The ratio (O / A) of the stripping section is 1:1.8, and the two-phase residence time is 10 minutes. After the primary extraction, the raffinate solution is drained to the nanofiltration device, and a polyamide nanofiltration membrane is used for cross-flow nanofiltration operation. The operating pressure of nanof...

Embodiment 2

[0033] Taking heavy rare earth as an example, add P507-200# kerosene extractant in the first stage of the extraction section, wherein the volume fraction of P507 is 40%, and the volume fraction of kerosene is 60%; add chlorinated rare earth material in the last stage of the extraction section Liquid (composition of liquid: YCl 3 1mol / L, HCl 1.5mol / L), water is added to the last stage of the stripping section and the washing section, and the extraction operation is carried out, wherein the ratio (O / A) of the extraction section is 1:1, and the two-phase residence time is 15min. The ratio (O / A) of the washing section is 2:1, and the two-phase residence time is 8 minutes. The ratio (O / A) of the stripping section is 1:1.8, and the two-phase residence time is 10 minutes. After the primary extraction, the raffinate solution is drained to the nanofiltration device, and a polyamide nanofiltration membrane is used for cross-flow nanofiltration operation. The operating pressure of nanof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com