System and method for measuring deformation of component in high and low temperature environments based on three-coordinate machine

A technology of a three-coordinate machine and a measuring system, which is applied to measuring devices, instruments, etc., can solve the problems of inability to accurately and stabilize the temperature control operation of the measured object, difficulty in adapting the three-coordinate operating system, and difficulty in high-precision temperature control, and achieve convenient and convenient The effect of practicality, wide adjustable temperature range and strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below in conjunction with embodiment.

[0039] Aiming at some deficiencies of the traditional measurement method in deformation and pose measurement in the high and low temperature environment of the irregular measured target, the present invention provides a method for measuring the deformation of structural parts in the high and low temperature environment based on the three-coordinate machine, which mainly solves the problem of It is difficult to realize the deformation measurement and pose measurement of complex and irregular structural parts by three-coordinate machine in high and low temperature environment.

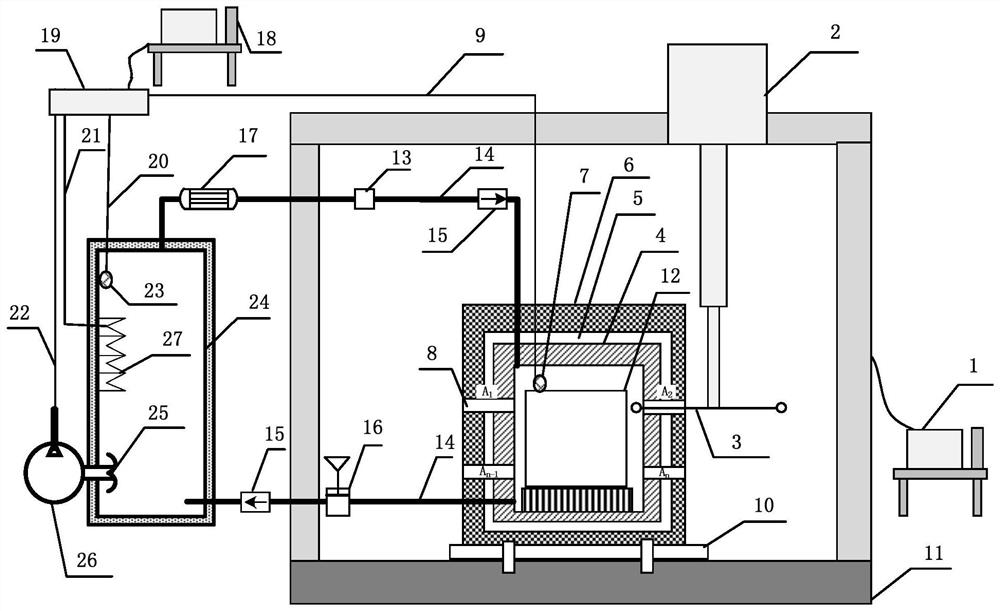

[0040] A three-coordinate machine-based component deformation measurement system in high and low temperature environments, such as figure 1 As shown, it specifically includes a mobile temperature control module, a cycle temperature control module, a measurement module, a test piece installation arrangement mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com