Vacuum isolation arc extinguishing device

An arc-extinguishing and vacuum technology, used in high-voltage air circuit breakers, electrical components, electrical switches, etc., can solve the problems of switch burnout, poor contact, stuck opening and closing operations, etc., to avoid corrosion and leakage current. The effect of generating and increasing the opening distance of the switch fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments in the present invention, all other embodiments obtained in the art without paying creative labor, all of the present invention.

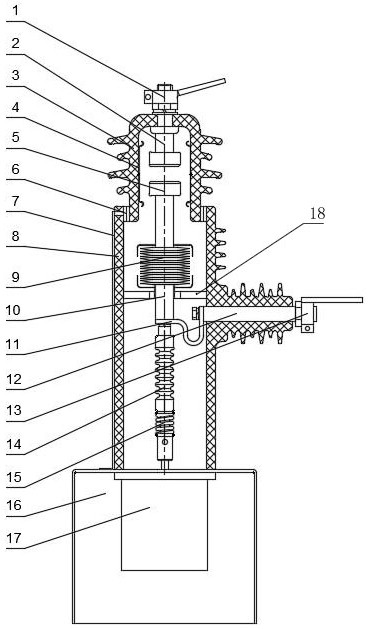

[0020] like figure 1 As shown, the present invention includes a switch base 16 and a movable end insulating sleeve 8 disposed on the switch base 16, a static insulating sleeve 3, a static contact 2, an movable contact 5, an offline terminal 1, an outflow terminal 13, The ground conductor 7, the bellows 9 and the actuation mechanism 17; the moving insulating sleeve 8 is vertically disposed on the switch base 16, and the bottom portion of the movable insulating sleeve 8 is fixed to the switch base 16, and the end insulation sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com