Elliptical gear transmission variable-speed stirring device and reaction kettle

An oval gear and stirring device technology, which is applied to mixers, feeding devices, and mixer accessories with rotating stirring devices, can solve the problems of low motor efficiency, high noise, and large volume, so as to improve the stirring effect and enhance the chaos. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

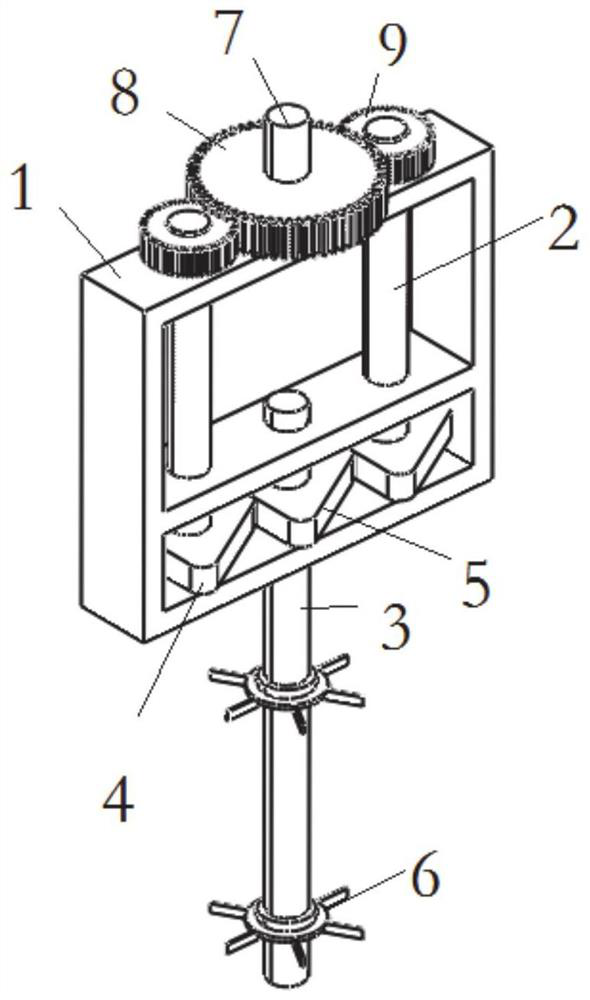

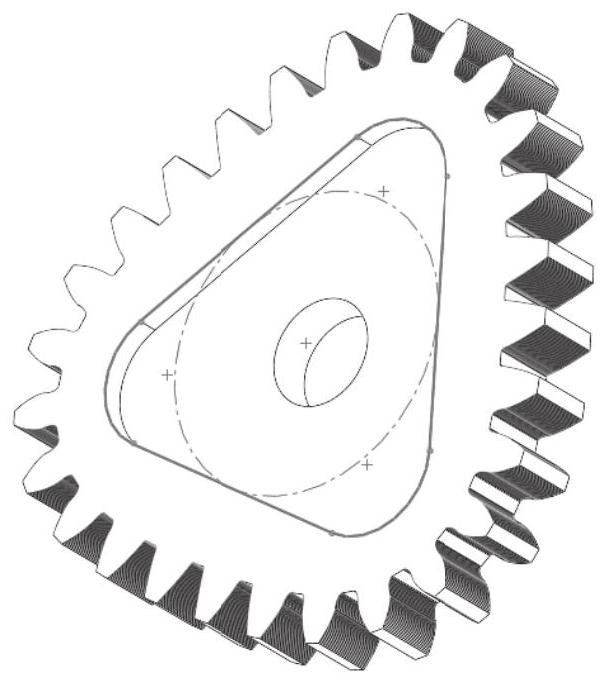

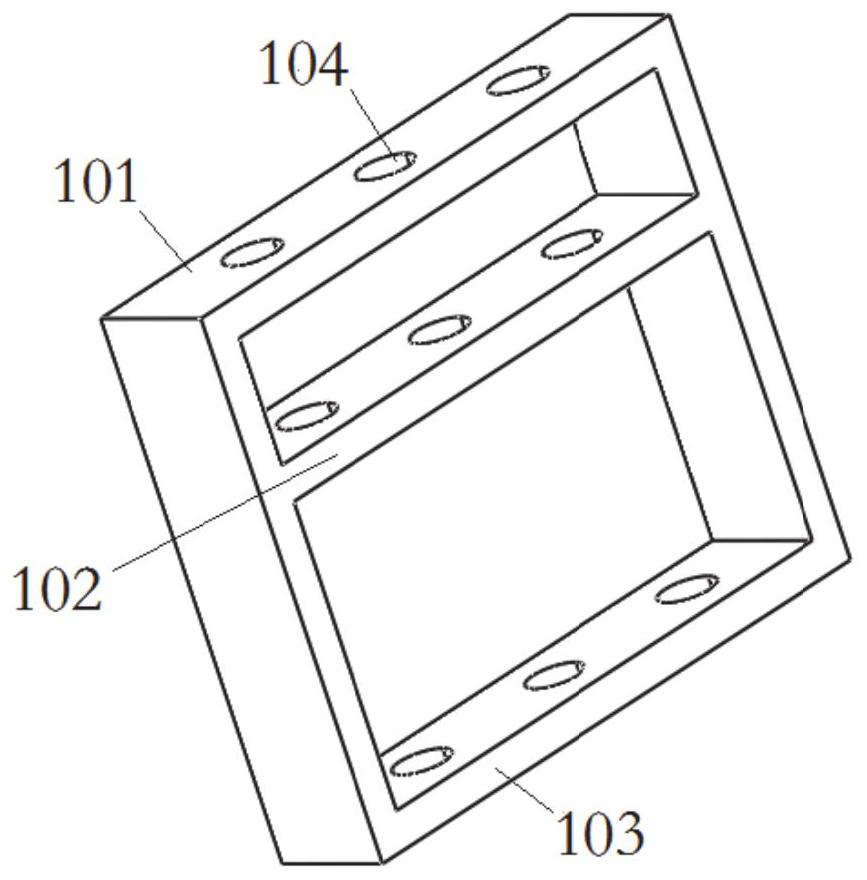

[0026] Such as figure 1 As shown, this embodiment provides an oval gear transmission variable speed stirring device, which mainly includes a fixed frame 1 and two first rotating shafts 2 arranged on the fixed frame, and the middle of the two first rotating shafts 2 in the fixed frame The position is provided with a second rotating shaft 3, wherein the first rotating shaft 2 and the second rotating shaft 3 are parallel to each other, a third-stage first oval gear 4 is connected to the bottom of the first rotating shaft 2, and a three-stage oval gear 4 is also installed on the top of the second rotating shaft. The second oval gear 5 of the second stage, the first oval gear and the second oval gear can mesh, so that the rotation of the first rotating shaft 2 drives the rotation of the second rotating shaft 3, and the bottom of the second rotating shaft 3 is also connected with a stirrer 6.

[0027] In this embodiment, the top of the fixed frame is provided with a third shaft 7, ...

Embodiment 2

[0040] Such as Figure 6 As shown, the embodiment of the present invention also discloses a reaction kettle, which is provided with a reaction kettle body 10 , and the oval gear transmission variable speed stirring device disclosed in the above embodiment is fixed on the inner wall of the reaction body 10 .

[0041] Such as Figure 4 As shown, in this embodiment, the outside of the reactor cylinder 10 is provided with a jacket cylinder 11, and the jacket cylinder 11 is welded together with the reactor cylinder 10,

[0042] Further, the top of the reactor cylinder 10 is flanged to a reactor upper seal 12, and the reactor upper seal 12 is provided with a feed pipe 13 and an air inlet pipe 14, while the reactor cylinder 10 The bottom is provided with a discharge pipe 15, so that the staff can add materials to be stirred through the reactor cylinder 10, and the stirred materials can be discharged through the discharge pipe 15.

[0043] In this embodiment, the upper part of the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com