A welding equipment for large gas regulating valve

A technology for gas adjustment and welding equipment, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to locate the flange, large flange volume, inconvenient flange adjustment, etc., to achieve continuous welding operation and reduce processing. Difficulty, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

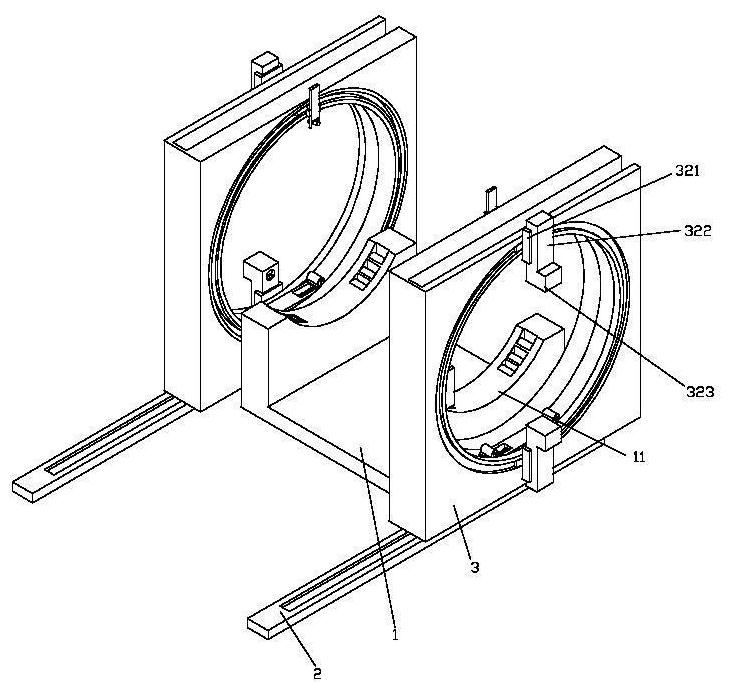

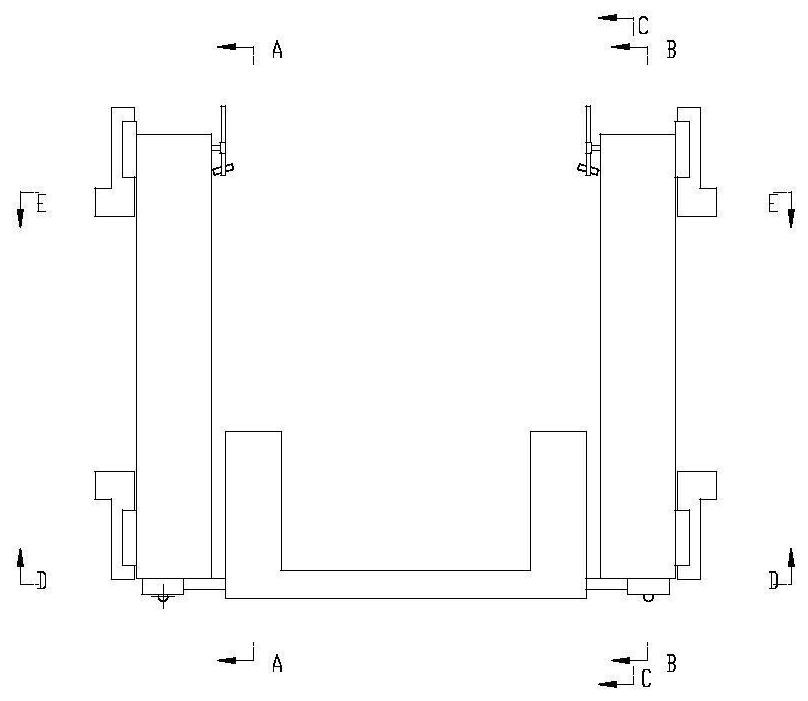

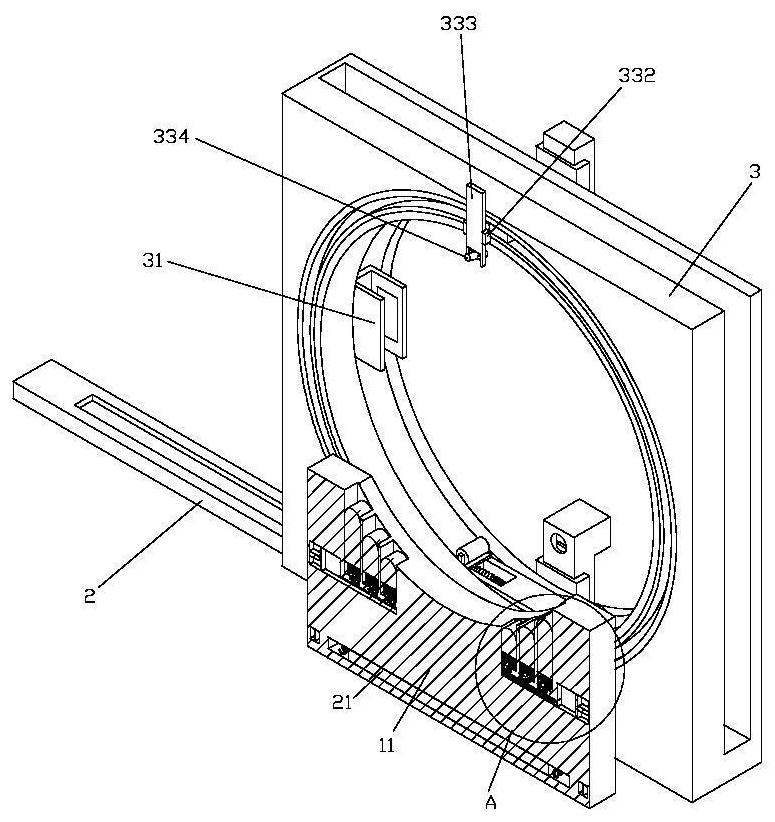

[0044] like Figure 1-28 As shown in the figure, a welding equipment for a large gas regulating valve includes a base plate 1, a support base 11 arranged on the base plate 1, and a material carrier frame 3 arranged on both sides of the base plate 1. There is a first material loading slot, a first movable slot is arranged on the side wall of the upper side of the loading frame 3, and two sets of first movable blocks 32 are arranged in the first movable slot. 32 is provided with a first connecting block 323, the first connecting block 323 is provided with a second movable groove, the second movable groove is provided with a first connecting rod 324, and one end of the first connecting rod 324 is provided with A first connecting spring 3241, the first connecting block 323 is provided with a motor 327 for driving the first connecting rod 324 to move in the second movable groove; A sixteenth movable slot is provided, a movable ring 33 is arranged in the sixteenth movable slot, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com