Emergency valve

An emergency valve and emergency room technology, applied in the direction of control valves, air release valves, brake components, brakes, etc., can solve the problems of high-pressure gas taking a long time, high-pressure gas discharge slowly, etc., and achieve convenient disassembly, replacement, cleaning and maintenance , Ease of maintenance and shortening the discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

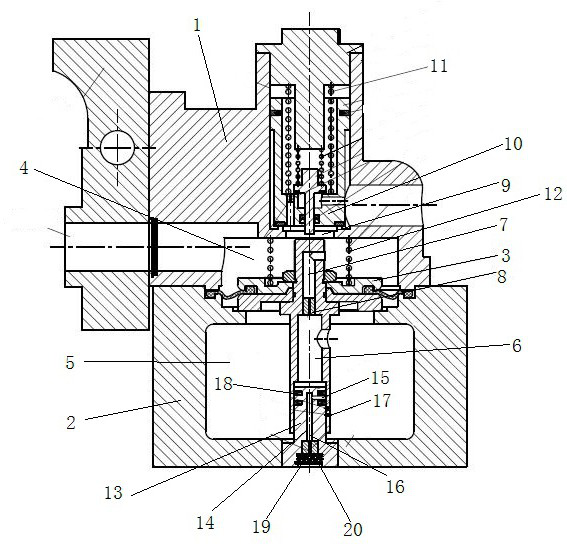

[0029] Specific embodiment 1 of the emergency valve of the present invention: In this embodiment, the emergency valve is connected to the brake pipe of the train braking system to accelerate the exhaust of the brake pipe as an example, and the structure and working principle of the emergency valve in the present invention are carried out introduce. Such as figure 1 As shown, the emergency valve includes a valve casing 1, a valve seat 2, and a valve assembly 3. The valve casing 1 and the valve seat 2 are buckled and sealed together, and at the same time, the valve casing 1 seals and presses the valve assembly 3 on the valve seat 2. superior. An exhaust channel is provided on the valve housing 1, one end of the exhaust channel is used to communicate with the brake pipe, and the other end is used to communicate with the atmosphere.

[0030]Specifically, the exhaust passage includes two parallel hole sections, and a main valve port 9 vertically connected to the two parallel hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com