Structure of anti-blocking drainage facility of retaining wall

A technology for drainage facilities and retaining walls, applied in underwater structures, soil protection, infrastructure engineering, etc., can solve the problems of consuming a lot of manpower and material resources, loss of drainage function, difficult disassembly and cleaning, etc., so as to be widely popularized and used , high practical value and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

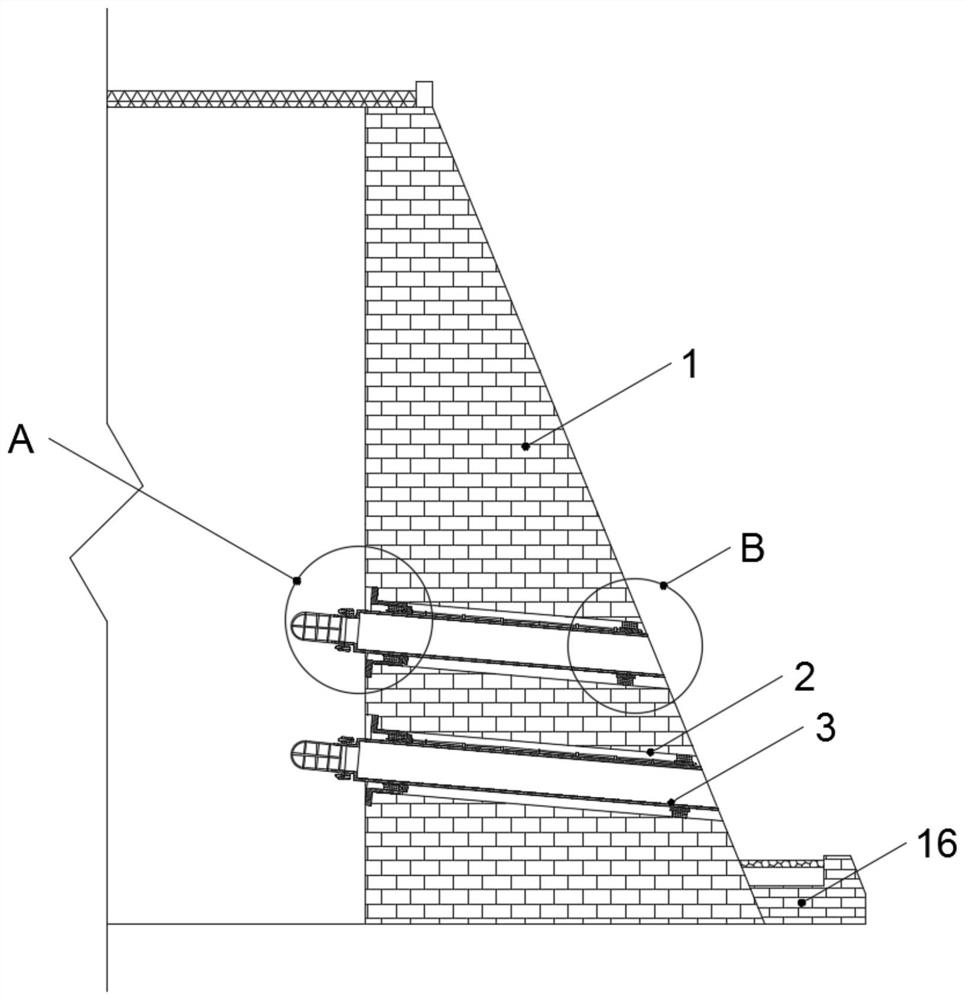

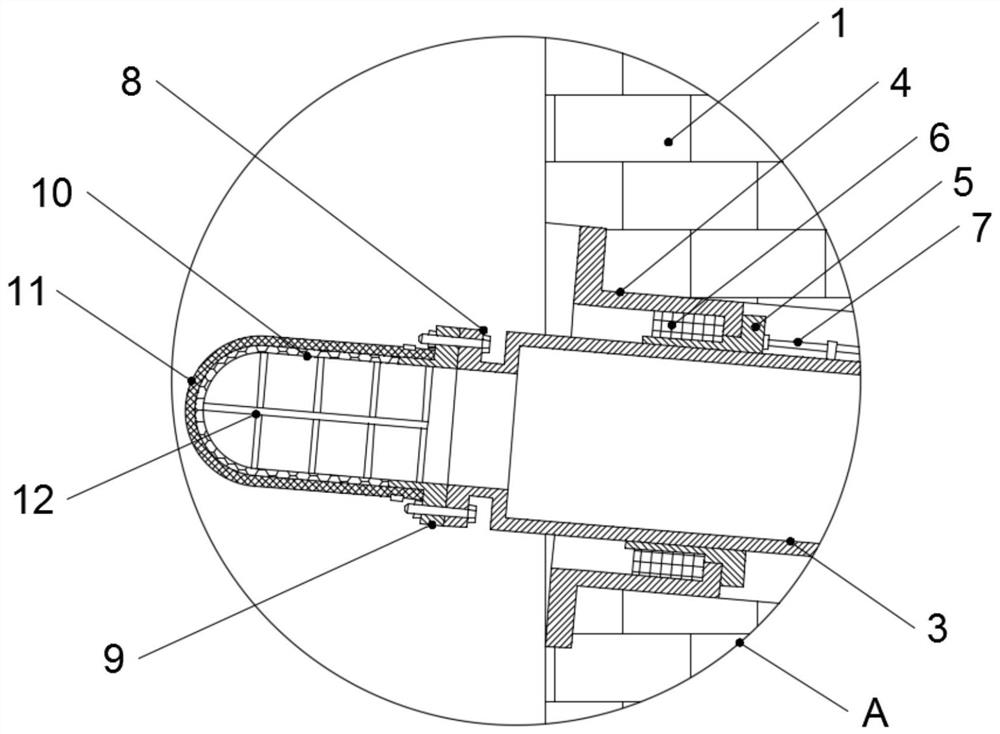

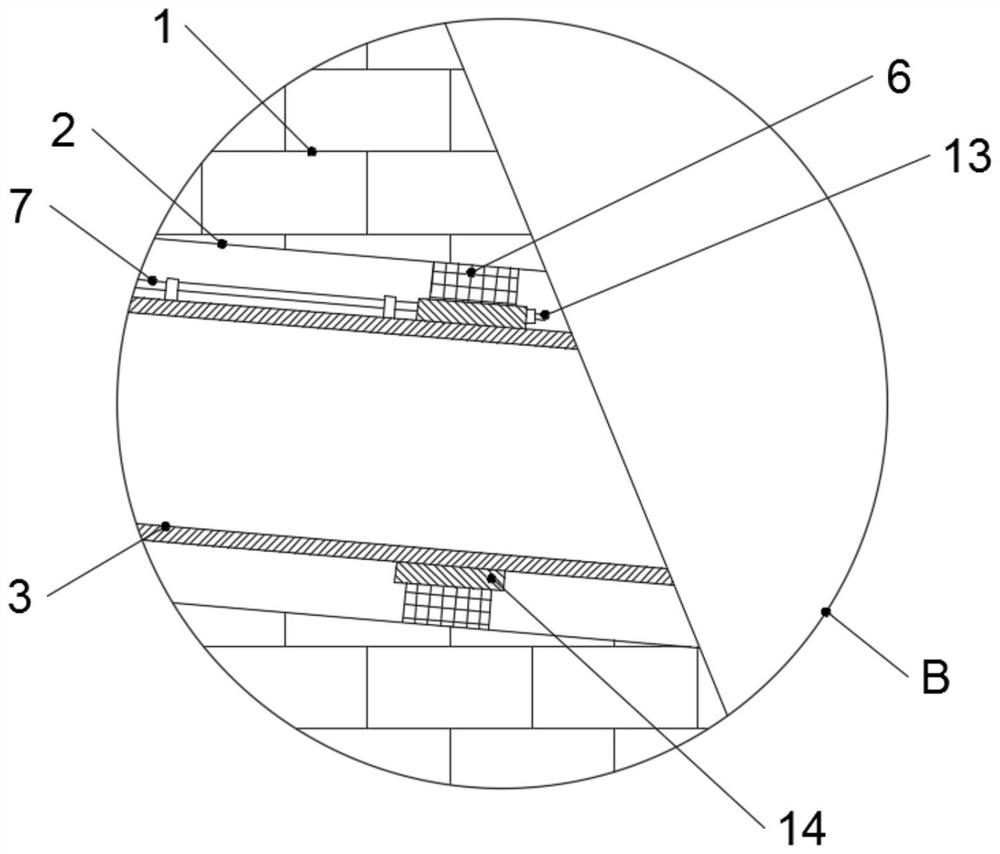

[0022] Example: such as Figure 1-4 As shown, the structure of a retaining wall anti-clogging drainage facility of the present invention includes a retaining wall 1, and the retaining wall 1 is provided with several groups of downwardly inclined drainage holes 2, and the two ends of the drainage holes 2 Respectively communicate with the outer surface of the retaining wall 1, the end of the drain hole 2 near the retaining side of the retaining wall 1 is fixedly connected with the limit seat 4, and the inside of the drain hole 2 is equipped with a drain pipe 3. The drain pipe 3 is fixedly fitted with a limiting ring 5 at one end close to the limiting seat 4, and is fitted with a mounting ring 14 at an end away from the limiting ring 5, and the outer sides of the limiting ring 5 and the mounting ring 14 are both The fixed sleeve is equipped with an inflatable ring 6, and the drain pipe 3 is provided with a connecting flange 8 at one end close to the retaining side of the retainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com