High-density polyethylene drainage device capable of cleaning sludge

A technology of high-density polyethylene and drainage devices, applied in water supply devices, cleaning sewer pipes, waterway systems, etc., can solve problems such as easy to be polluted, labor and time-consuming, not clean enough, and achieve the effect of ensuring smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

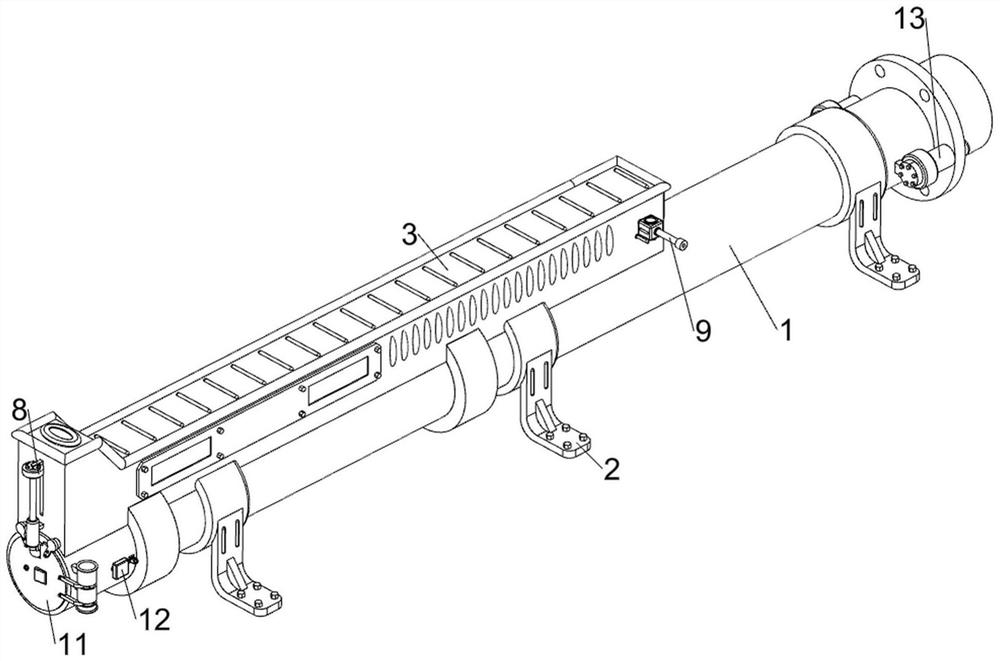

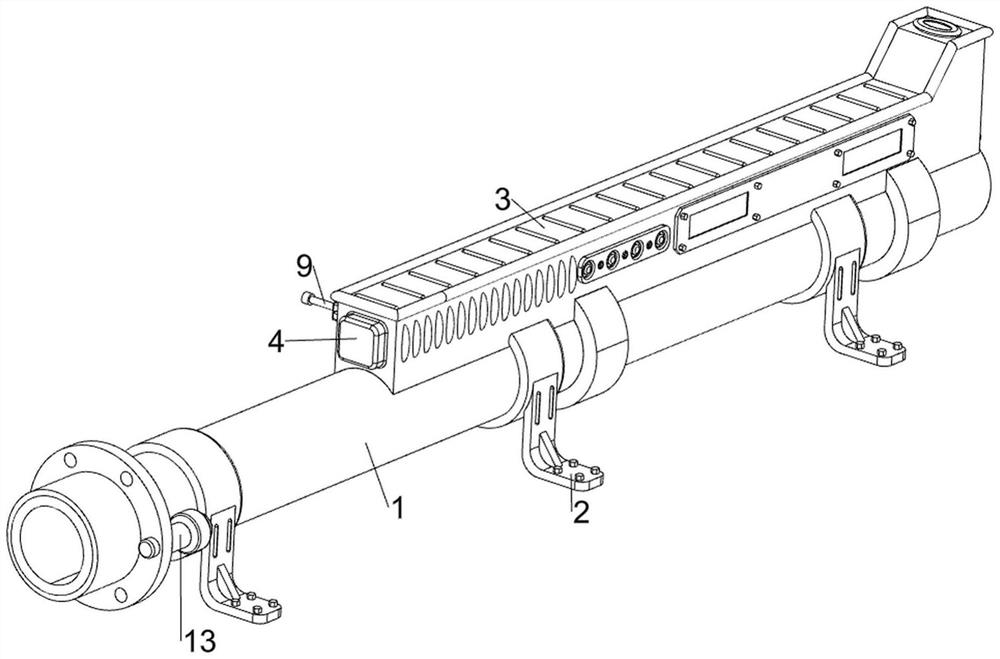

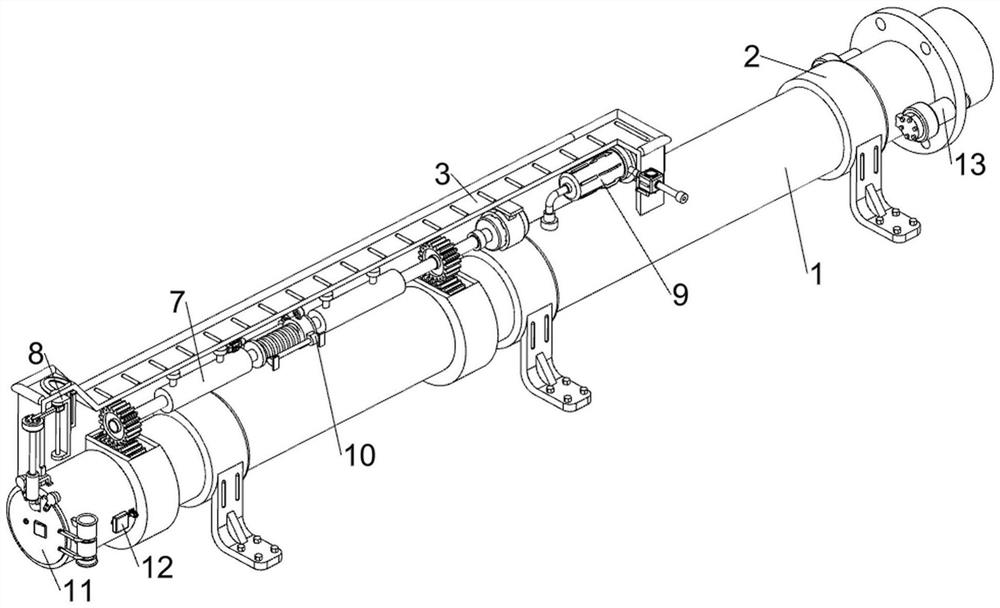

[0038] like Figure 1 ~ 9As shown, the present embodiment discloses a high-density polyethylene drain device that can be cleaned to the sludge, including a pipe 1, a bracket 2, a frame 3, a rotary ring 5, a scraper 6, a scraping mechanism 7, and a detection mechanism 8, a pipe 1 The outer interval is evenly connected with three brackets 2, and the left side of the upper portion of the pipe 1 is connected to the left side of the pipe 1, and the left and right sides of the pipe is connected to the rotation ring 5, and the inside of the rotation ring 5 is symmetrically connected to the blade 6, and the box A scraping mechanism 7 is provided between the upper side of the body 3 and the rotary ring 5, and the casing 3 and the upper left side of the upper portion of the conduit 1 are provided with a detection mechanism 8.

[0039] When the user uses polyethylene drains, first, the user presses the power source switch, for the device, and the pipe 1 is connected to the right side, press t...

Embodiment 2

[0044] like Figure 1 ~ 3 , Figure 10 ~ 18 As shown in some embodiments, there is also included a cleaning assembly 9, and the cleaning assembly 9 includes a fixed seat 91, a spray head 92, a water pump 93, a connecting tube 94, a water pipe 95, and a solenoid valve 96. The upper intermediate connection of the upper portion of the pipe 1 is fixed. The seat 91, the housing 3 is attached to the right side of the housing 3, and the water pump 93 is connected between the inner side of the fixed seat 91, and the lower portion of the connecting pipe 94 is connected to the left side, and the water pump 93 is between the front right side of the frame 3. Connected to the water supply pipe 95, the right side of the front portion of the frame 3 is mounted with a solenoid valve 96, and the solenoid valve 96 cooperates with the water pipe 95.

[0045] Also included with the linkage assembly 10, the linkage assembly 10 includes a guide bar 101, the moving seat 102, the thread sleeve 103, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com