Detachable wallboard mounting kit without bottom plate and mounting method

A technology for mounting parts and wall panels, applied in the field of detachable wall panel installation kits without bottom plate, can solve the problems of moldy hard pack/wall panel surface layer, cost effect damage, and difficulty in removing straight nails, etc., and achieves high firmness, Material saving, easy removal and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0037] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

[0038] In order to make the above objects, features, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

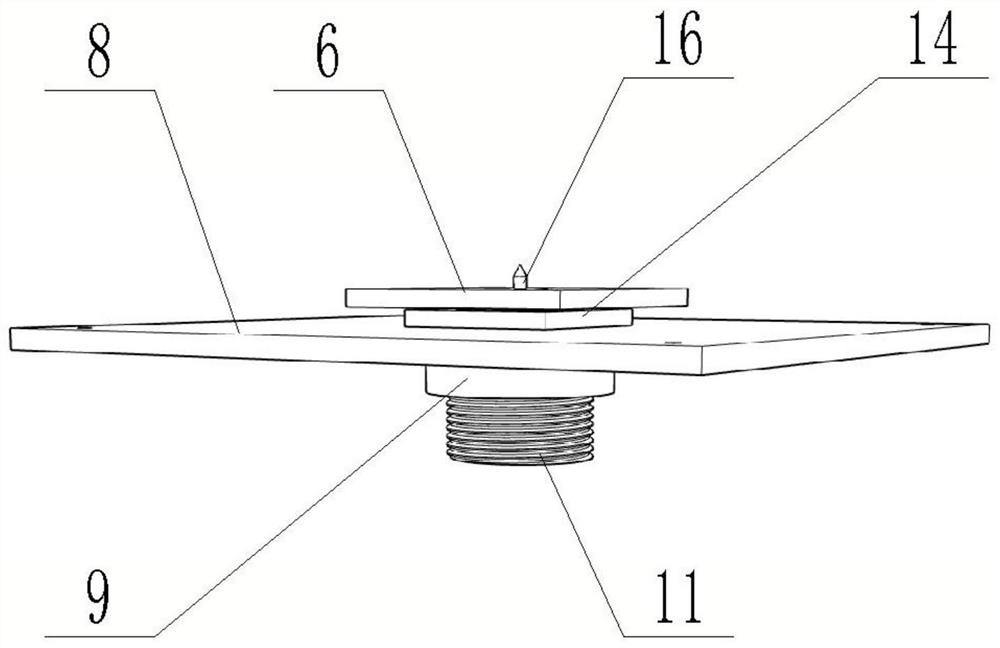

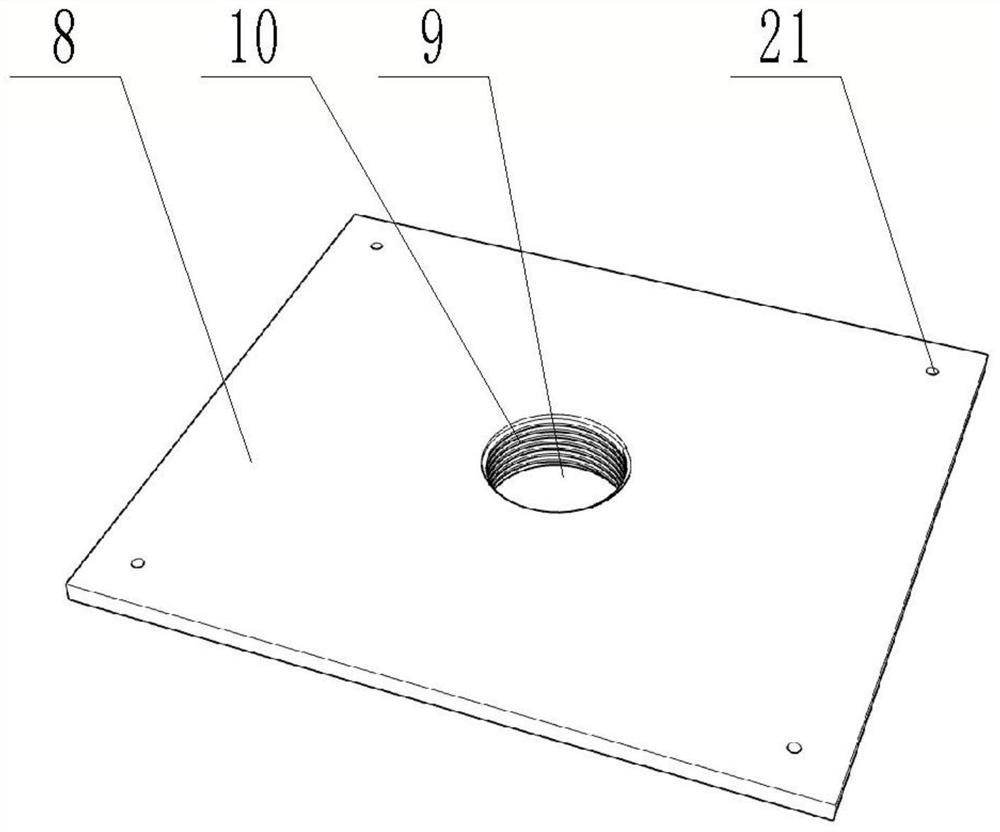

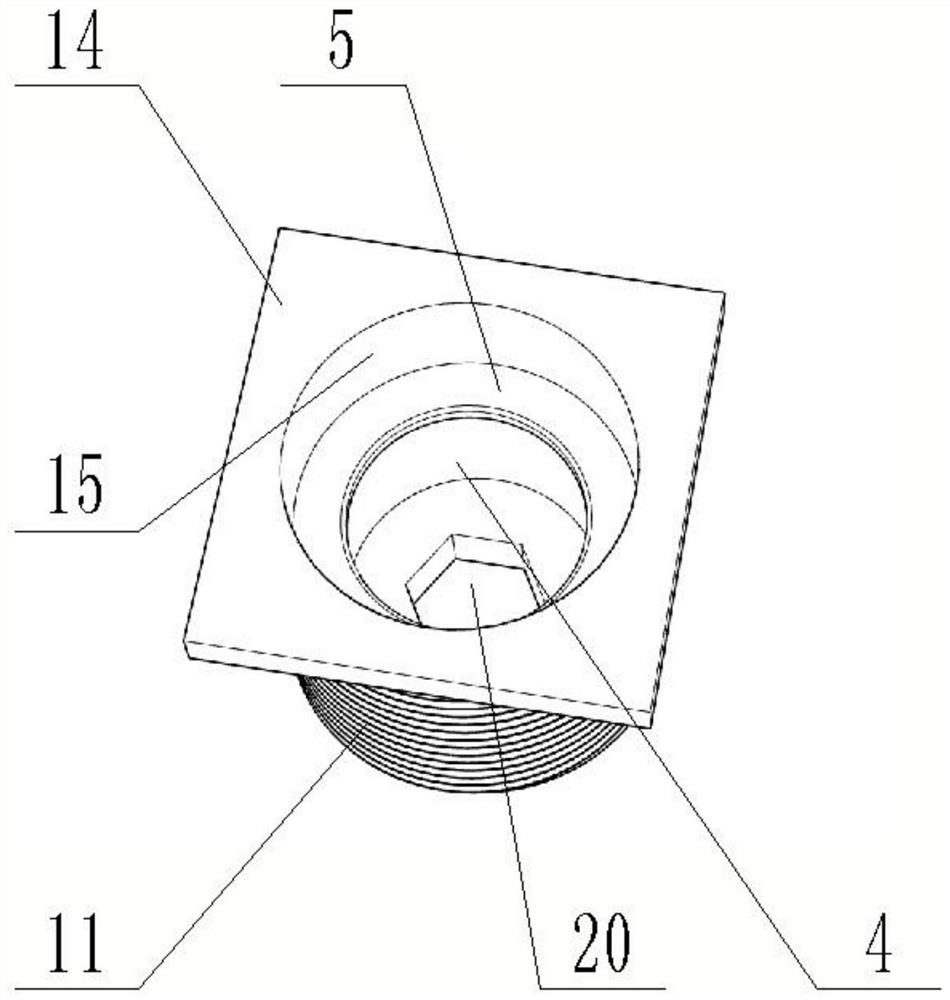

[0039] The present invention provides a wall panel mounting kit for removably removably disassembly, including a gap between the wall 1 and the wall plate 2, and the wall 1 is located on one side of the wall plate 2. 3 The third mounting member is fixed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap