Method for reducing dilution in ore body mining

An ore body and dilution technology, which is applied in ground mining, mining equipment, earth drilling and mining, etc., can solve problems such as ore dilution, endanger mine economic benefits, ore mining safety hazards, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

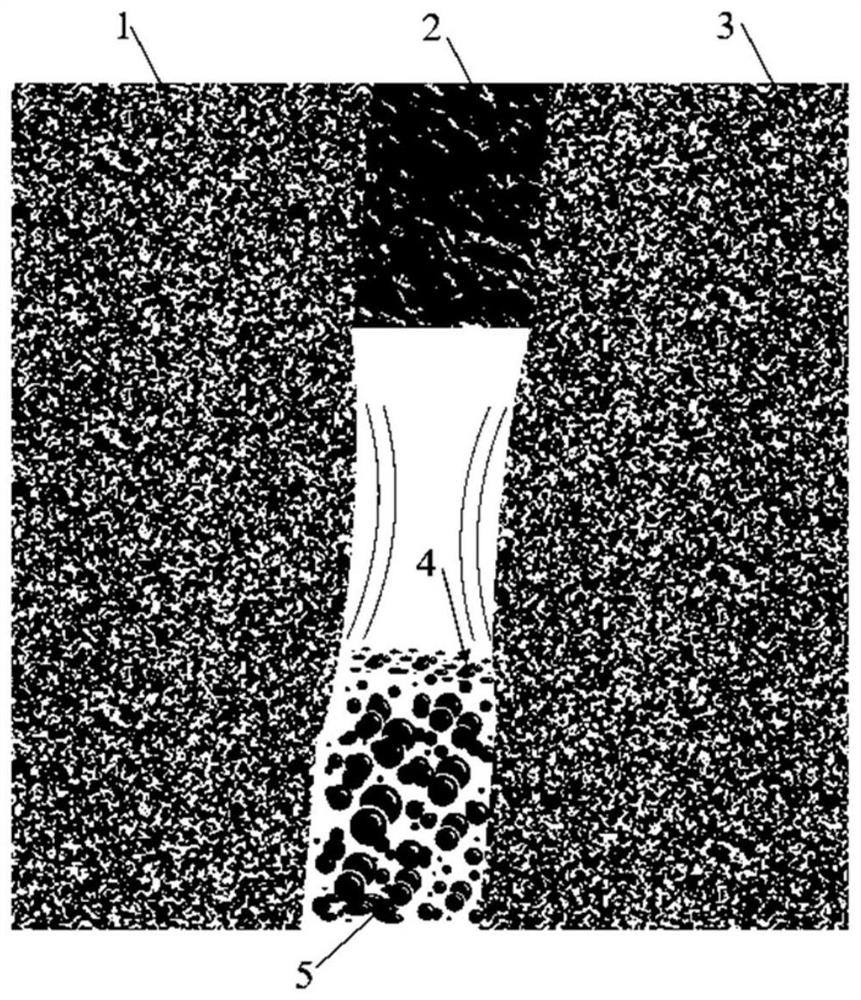

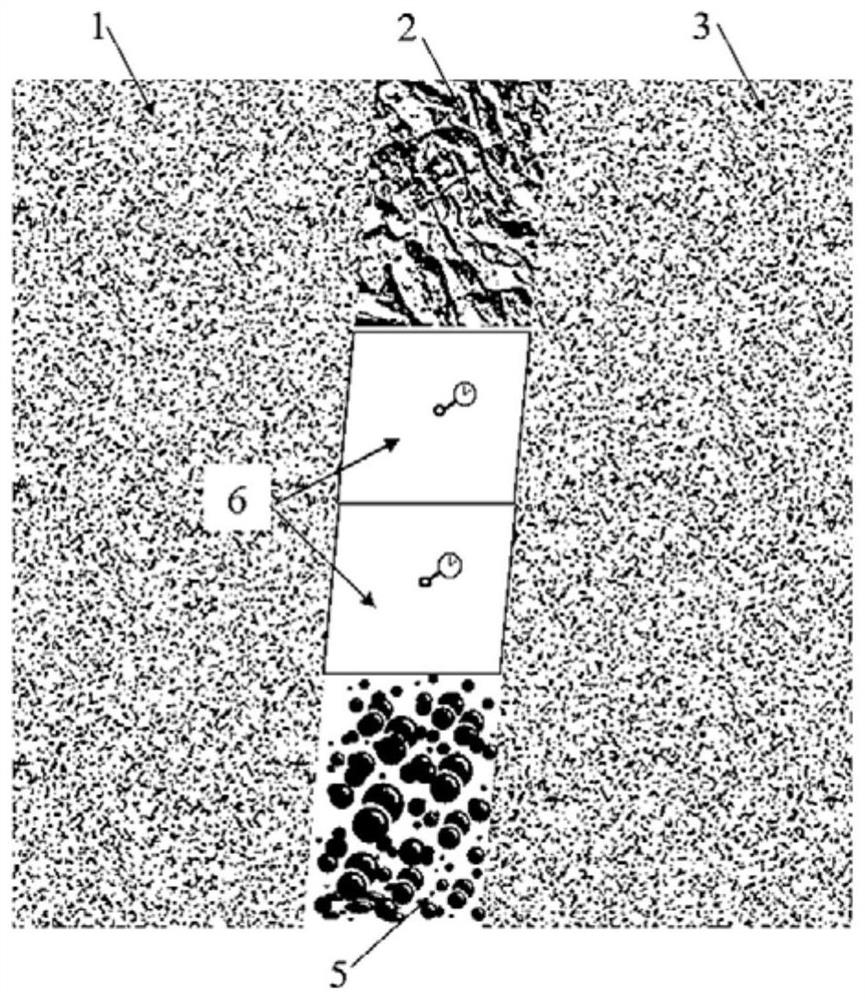

[0038] Aiming at the problem that when using the open field method to mine the ore body with broken ore and surrounding rock, the surrounding rock of the upper and lower walls is easy to cross and mix into the collapsed ore, resulting in the dilution of the ore, and serious safety accidents may occur. The example provides a method for reducing dilution in ore body mining. In this method, the air bag is placed above the caving ore, which can prevent the surrounding rock from crossing and mixing with ore, thereby effectively solving the problem of ore dilution.

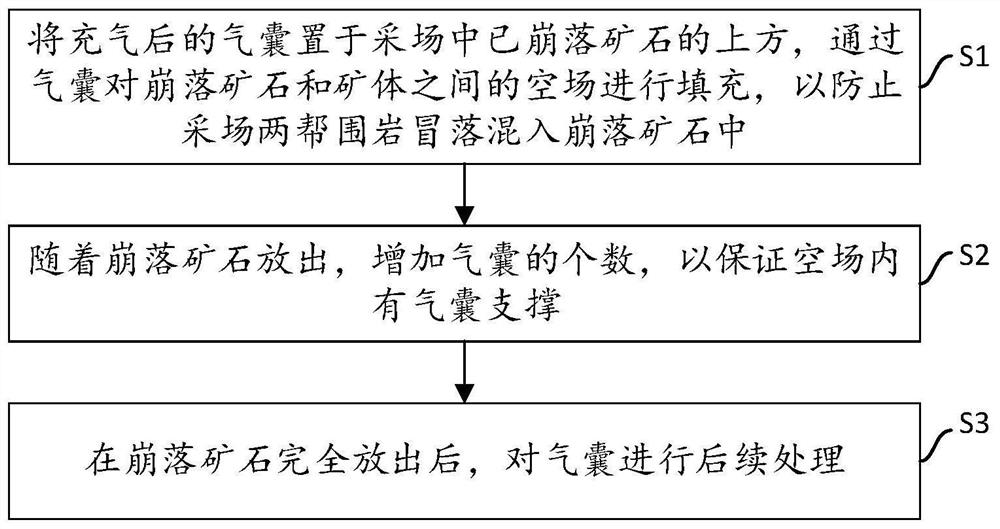

[0039] Specifically, the execution flow of the method is as follows figure 1 shown, including the following steps:

[0040] S1, place the inflated airbag above the caving ore i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com