Device for testing friction force of hydraulic cylinder in hydraulic equipment and testing method thereof

A technology of hydraulic equipment and testing equipment, which is applied in the direction of fluid pressure actuation equipment, fluid pressure actuation system testing, mechanical equipment, etc., and can solve problems such as inconvenient quick alignment and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

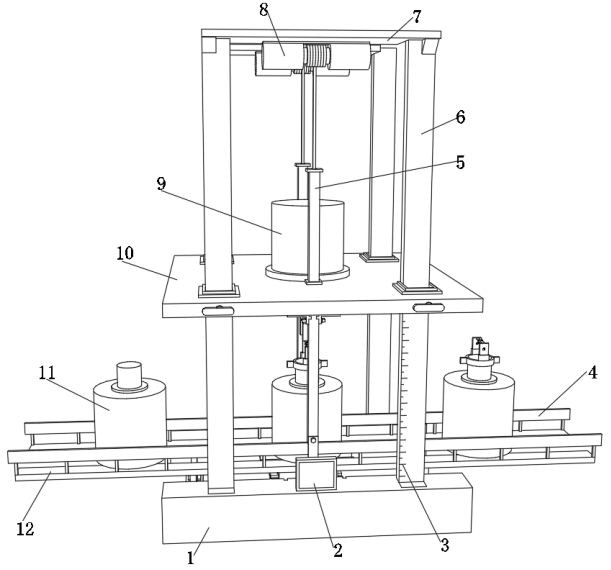

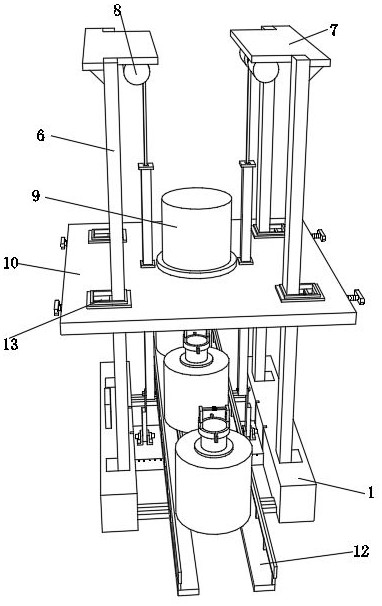

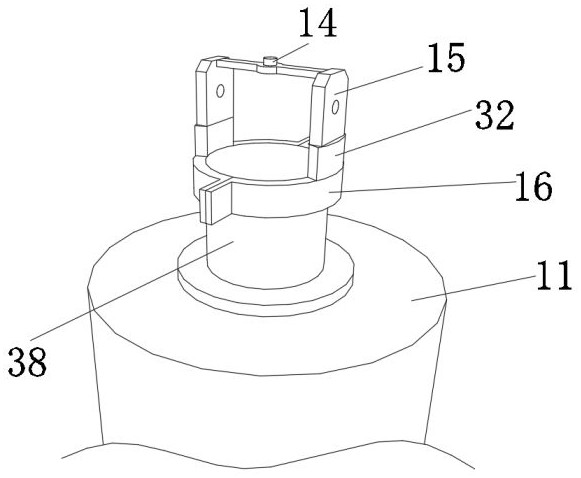

[0044] A hydraulic cylinder friction testing device in hydraulic equipment, such as Figure 1-9 As shown, it includes a support plate 25 that is slidably connected between a group of support blocks 1, the outer wall of one side of the support block 1 is fixed with a connecting plate 26, and the outer wall of the top of the connecting plate 26 is fixed with two sliding support rods 27 by screws. , the top outer wall of the sliding support rod 27 is fixed with an electric transmission plate 12 by screws, the hydraulic cylinder 11 to be tested is placed on the top outer wall of the electric transmission plate 12, the second piston rod 38 is plugged into the inner wall of the hydraulic cylinder 11 to be tested, and the top outer wall of the support block 1 passes through Screws are fixed with a plurality of guide rods 6, the outer walls of the guide rods 6 are slidably connected with a movable plate 10, the outer wall of the movable plate 10 is provided with a plurality of fixed th...

Embodiment 2

[0058] A test method for hydraulic cylinder friction testing device in hydraulic equipment, such as Figure 1-9 shown, including the following steps:

[0059] S1: The staff pushes the sliding support rod 27 to adjust the distance between the two electric transmission plates 12, fixes the sliding support rod 27 on the connecting plate 26 with screws, and places the hydraulic cylinder 11 to be tested on the electric transmission plate 12;

[0060] S2: The worker inserts the plug-in block 23 into the plug-in slot 29, fixes the plug-in block 23 on the pull rod 5 through a pin, controls the electric hoist 8 through the control panel 2 to drive the pull rod 5 to move, and adjusts the overall height of the moving plate 10 ;

[0061] S3: The worker tightens all the threaded rods 19 on the outer wall of the moving plate 10, then removes the plug-in stopper 23, then turns the rotating connecting rod 24 to the side of the pull rod 5, and fixes the rotating connecting rod 24 by rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com