Environment-friendly chemical fiber leftover material collecting device

A collection device and a technology of chemical fiber yarn, which is applied in the field of environmental protection chemical fiber yarn scrap collection device, can solve the problems of low efficiency of chemical fiber scrap, and achieve the effect of improving convenience and collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

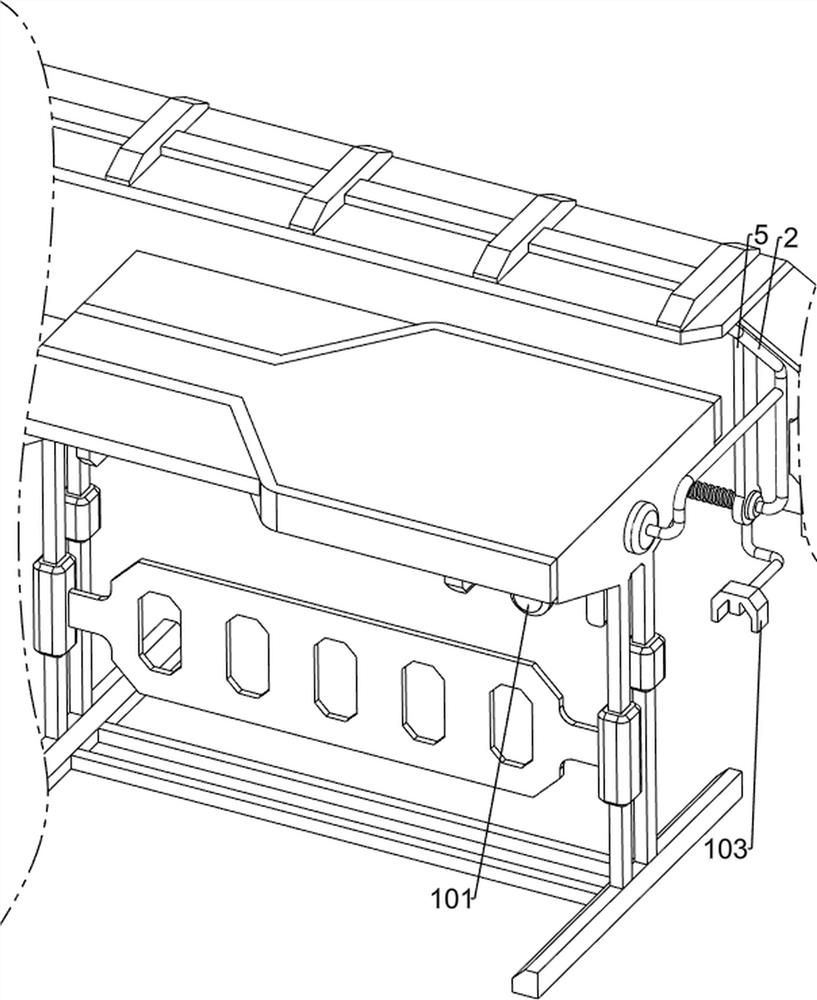

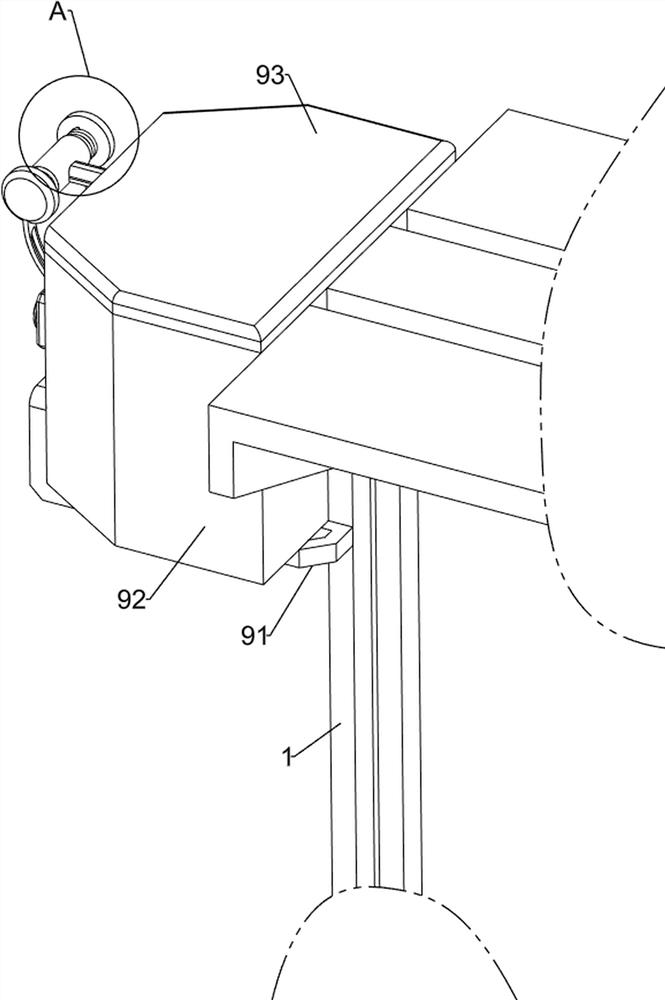

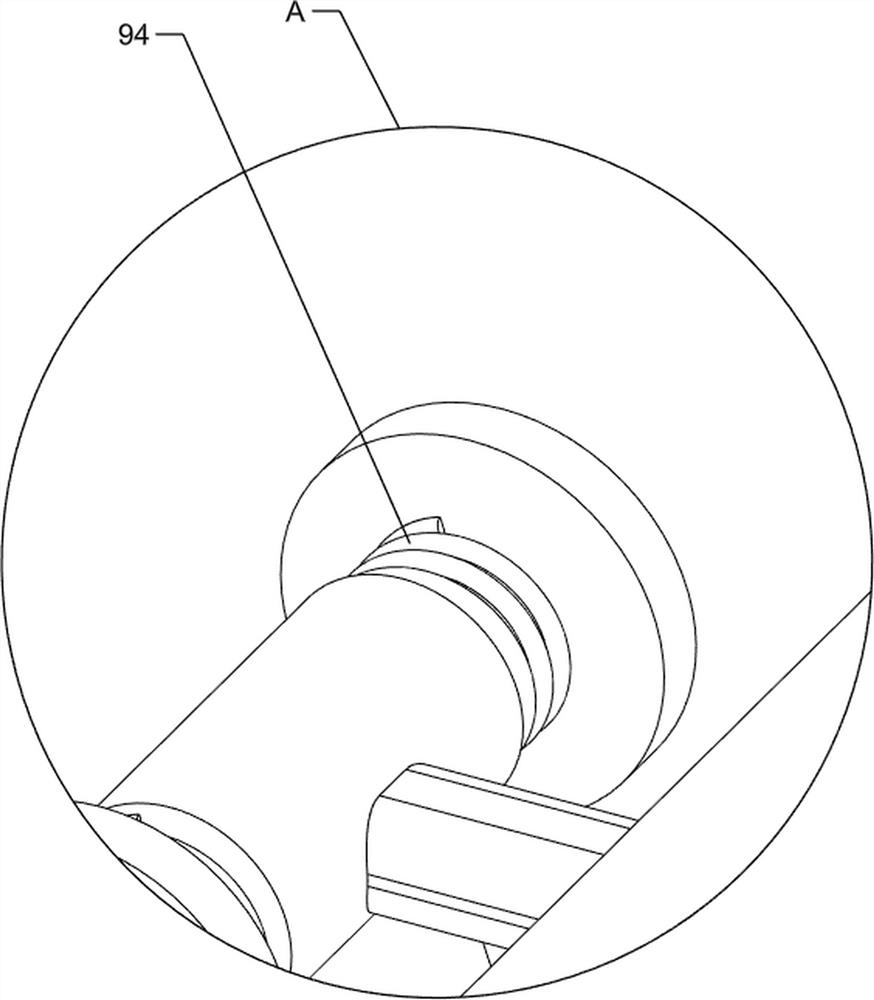

[0073] A kind of collection device based on environmental protection chemical fiber silk leftovers, such as Figure 1-Figure 3 As shown, it includes a first support frame 1, a second support frame 2, a first baffle plate 3, a screw mandrel 4, a first movable plate 5, a motor 6, a third support frame 7, a clamping mechanism 8 and a collection mechanism 9 , the upper part of the first support frame 1 is provided with the second support frame 2, the upper part of the second support frame 2 is provided with the first baffle plate 3, the rear side lower part of the second support frame 2 is rotatably provided with a screw rod 4, and the screw rod 4 is threaded The formula is provided with a first movable plate 5, the first movable plate 5 is slidably connected with the second support frame 2, the left side of the second support frame 2 is provided with a third support frame 7, and a motor 6 is installed on the bottom of the third support frame 7, The output shaft of the motor 6 is ...

Embodiment 2

[0076] In a preferred embodiment of the present invention, as Figure 4-Figure 6 As shown, the clamping mechanism 8 includes a fourth support frame 81, a first slide rail 82, a splint 83, a first spring 84 and a material brush 85, and a fourth support frame 81 is provided on the front side of the upper part of the first movable plate 5. The bottom of the four supporting frame 81 is provided with a first slide rail 82, and two splints 83 are slidably arranged on the first slide rail 82. The left and right sides of the first slide rail 82 are equipped with a first spring 84, and the first spring 84 inner end Connected to the splint 83 , the outer end of the first spring 84 is connected to the fourth support frame 81 , and a material brush 85 is installed between the two splints 83 .

[0077] When people start the motor 6, the movement of the first movable plate 5 to the left can drive the fourth support frame 81 to move to the left, and then can drive the first slide rail 82 to ...

Embodiment 3

[0081] In a preferred embodiment of the present invention, as figure 1 , figure 2 and Figure 7-Figure 14 As shown, a material guide mechanism 10 is also included, and the material guide mechanism 10 includes a sixth support frame 101, a first movable block 102, a first wedge block 103 and a second movable plate 104, and the first support frame 1 top is provided with a second Six bracing frames 101, the sixth bracing frame 101 bottom is rotatably provided with the first movable block 102, the first movable plate 5 bottom is provided with the first wedge-shaped block 103, the first wedge-shaped block 103 cooperates with the first movable block 102, the first The upper part of the support frame 1 is slidably provided with a second movable plate 104 , and the second movable plate 104 cooperates with the first movable block 102 .

[0082] When the first movable plate 5 moved to the left, the first movable plate 5 could drive the first wedge block 103 to move to the left, and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com