Slide way assembly for assembling combined nut

A combined, nut technology, used in screwdrivers, wrenches, manufacturing tools, etc., can solve problems such as inconvenience to carry, different nut supply requirements, and nut clogging at the feed port.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

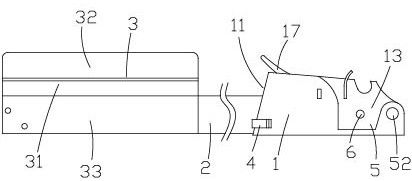

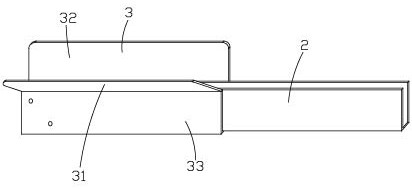

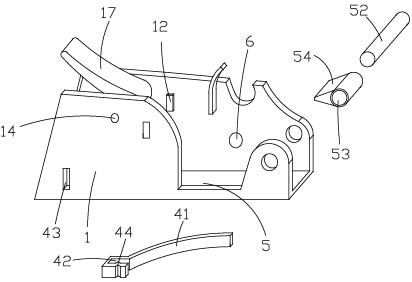

[0025] Figure 1 to Figure 5 It is a structural schematic diagram of the present invention.

[0026] The reference signs are: assembly head 1, interface end 11, stopper 12, assembly end 13, anti-rotation part 14, anti-rotation rod 15, eccentric wheel 16, trigger 17, locking part 18, external slideway 2. Introduction mechanism 3, guide plate 31, baffle plate 32, connection part 33, push mechanism 4, shrapnel 41, fixing clip 42, fixing hole 43, clamping protrusion 44, stirring port 5, pushing mechanism 51, connecting rod 52, Pushing and blocking block 53, pushing and blocking convex body 54, attracting magnet 6, and included angle α.

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

[0028] Such as Figure 1 to Figure 5 as shown,

[0029] A combined slideway assembly for nut assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com