Novel pillar structure for roll-on roll-off ship

A pillar structure and pillar technology, which is applied in the field of new pillar structures, can solve problems such as the inability to eliminate stress concentration points, easy fatigue cracks, and small structural strength margins, so as to achieve reasonable load distribution, increase ultimate strength, and favorable structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

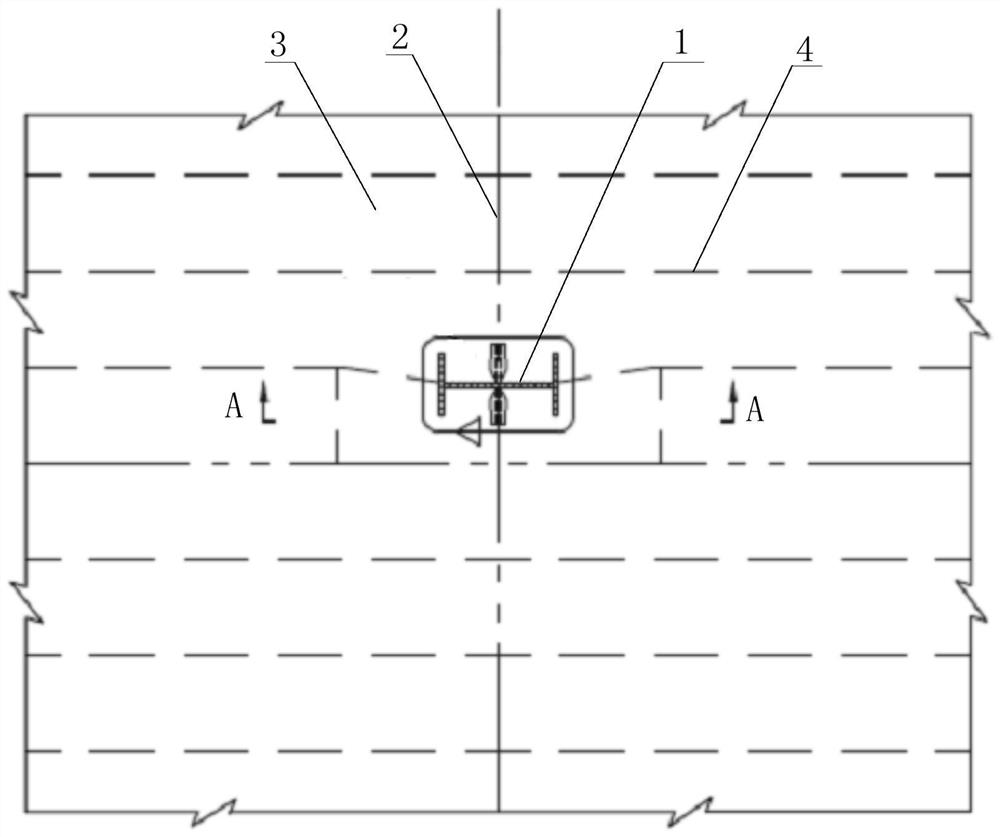

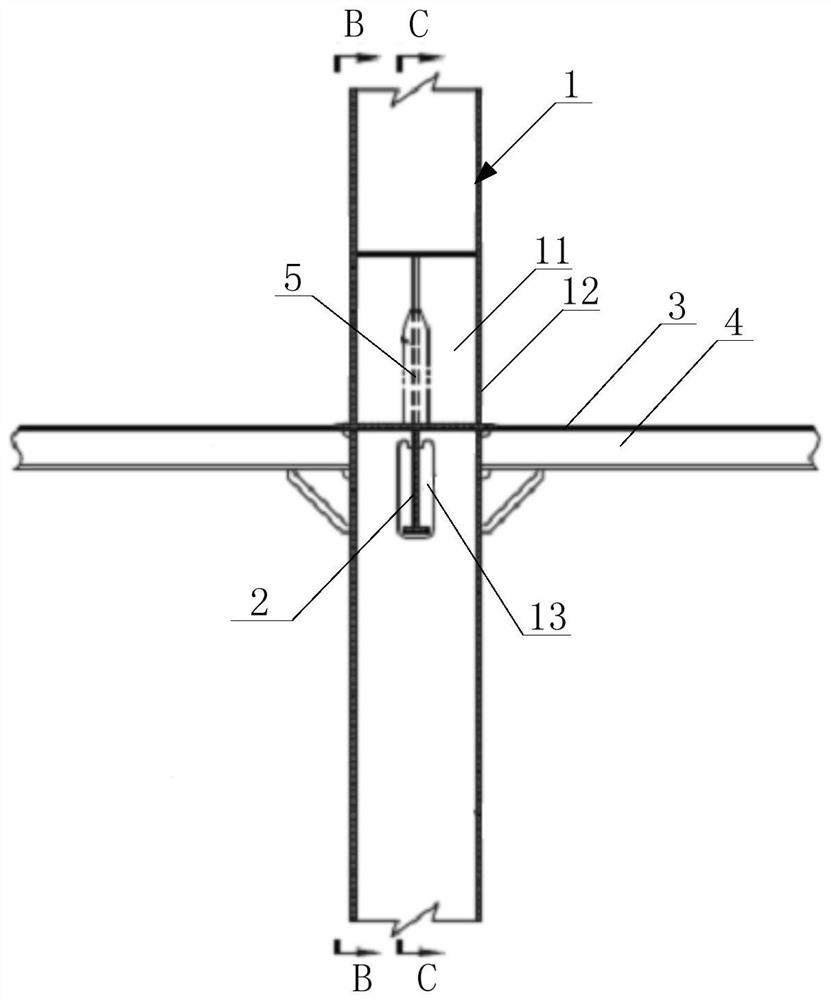

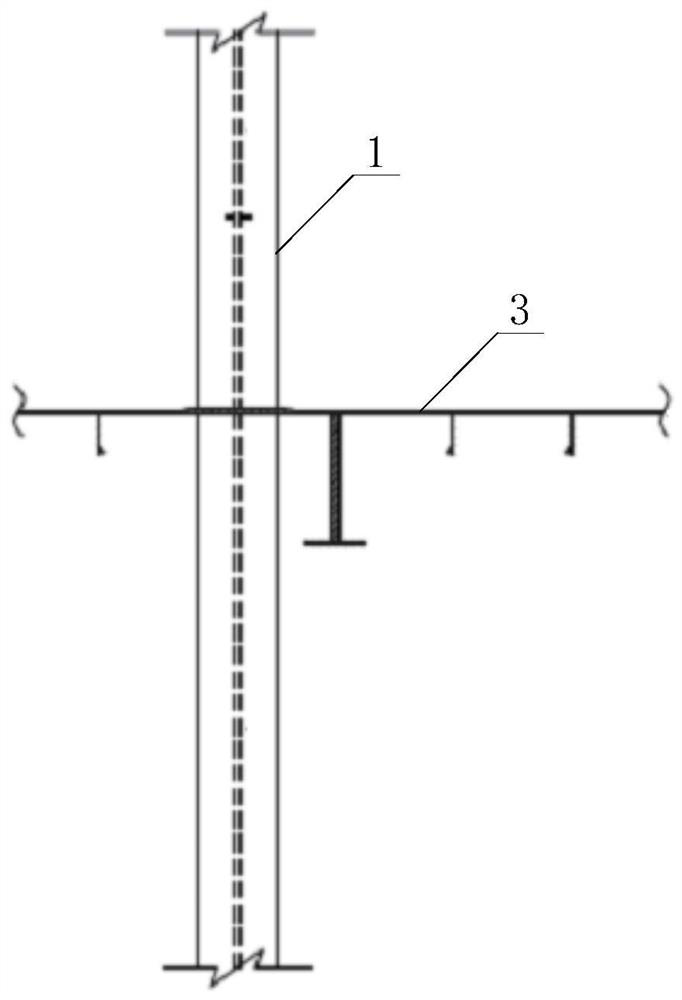

[0023] Below according to the accompanying drawings Figure 1 to Figure 5 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0024] see Figure 1 to Figure 5 , a novel pillar structure for ro-ro ships according to an embodiment of the present invention, comprising a pillar 1 and a deck beam 2; the pillar 1 is vertically penetrated and connected to a deck 3 of a hull; the pillar 1 includes a pillar web 11 and two pillar panels 12, the pillar panels 12 are vertically fixed on both sides of the pillar web 11; the pillar web 11 is provided with a through hole 13, the deck strong beam 2 is arranged along the width direction of the hull and supported under the deck 3, the deck strong The beam 2 is partly passed through the through hole 13 .

[0025] A shrinkage section 21 is formed in the middle of the deck beam 2, and the width of the shrinkage sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com