Adsorption device

A technology of adsorption device and adsorption parts, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of long time consumption, inability to adjust the adsorption area conveniently, and inaccurate adjustment, and achieve the effect of convenient and accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

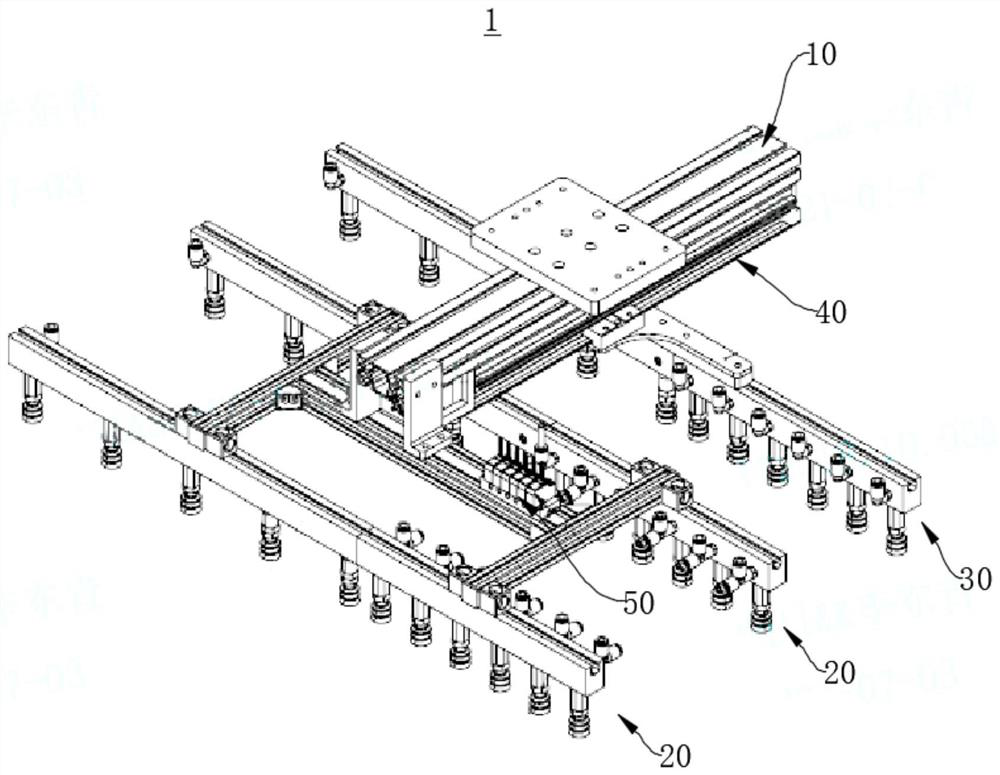

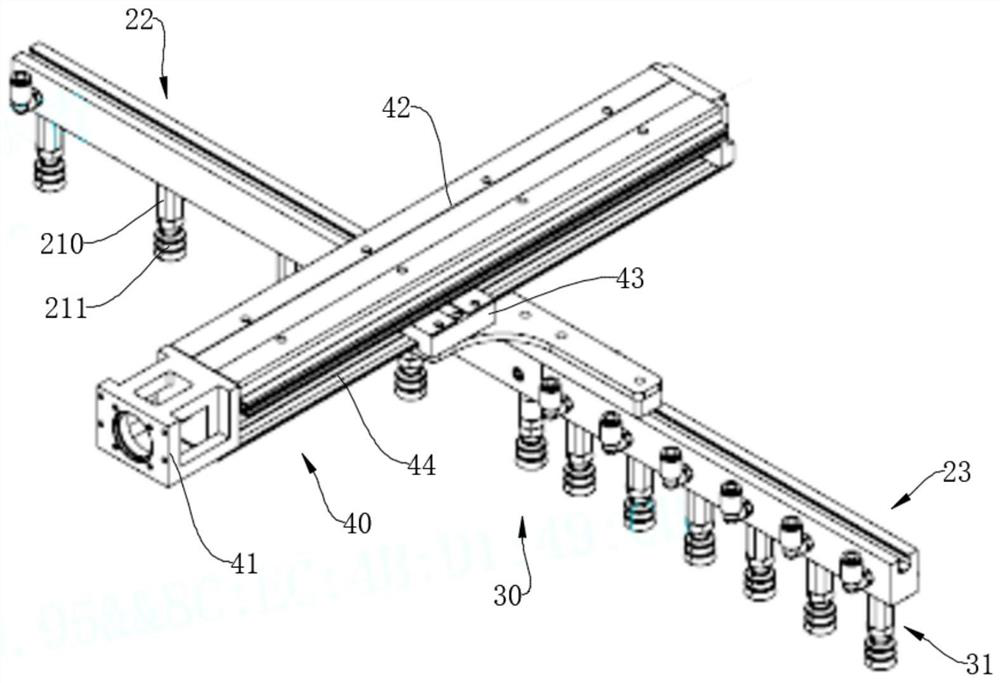

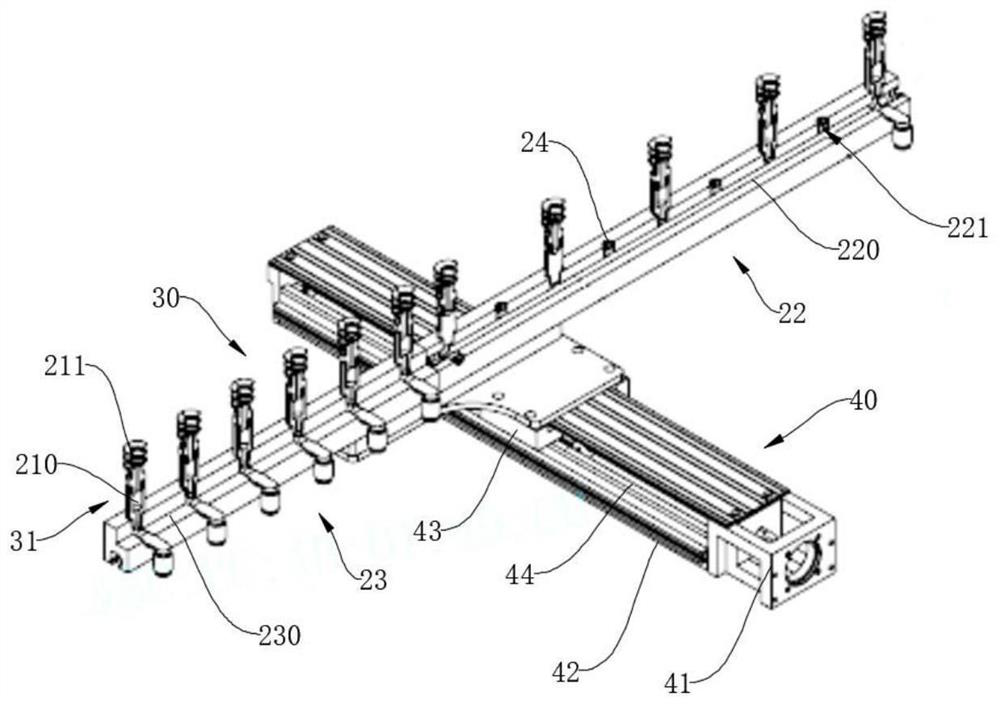

[0033] Refer below Figure 1-Figure 8 The adsorption device 1 according to the embodiment of the present invention is described.

[0034] Such as figure 1 As shown, the adsorption device 1 according to the embodiment of the present invention includes: a frame 10 , a first adsorption assembly 20 , a second adsorption assembly 30 , a driving assembly 40 and a control valve 50 . The frame 10 can play the role of fixing and installing the adsorption device 1 as a whole. Both the first adsorption assembly 20 and the second adsorption assembly 30 can play an adsorption role, thereby improving the adsorption stability of the adsorption device 1, wherein the first adsorption assembly 20 includes: a series adsorption assembly and a parallel adsorption assembly, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com