Excavator hydraulic oil warming-up system and control method thereof

A control method and technology of hydraulic oil, applied in the direction of earthmoving machine/shovel, construction, etc., can solve the problem of long hydraulic oil warm-up time, large wear and impact of hydraulic components and radiators, and reduce the reliability of hydraulic components and other problems to achieve the effect of shortening the hydraulic oil warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the cold area in winter, when the direct-driven fan excavator is open, in order to rapidly reach the hydraulic oil temperature, the hydraulic oil temperature in the hydraulic tank is 40 ° to 60 ° in the optimum temperature range, and the present invention provides a Excavator hydraulic oil heating system.

[0023] The technical solution adopted by the present invention is:

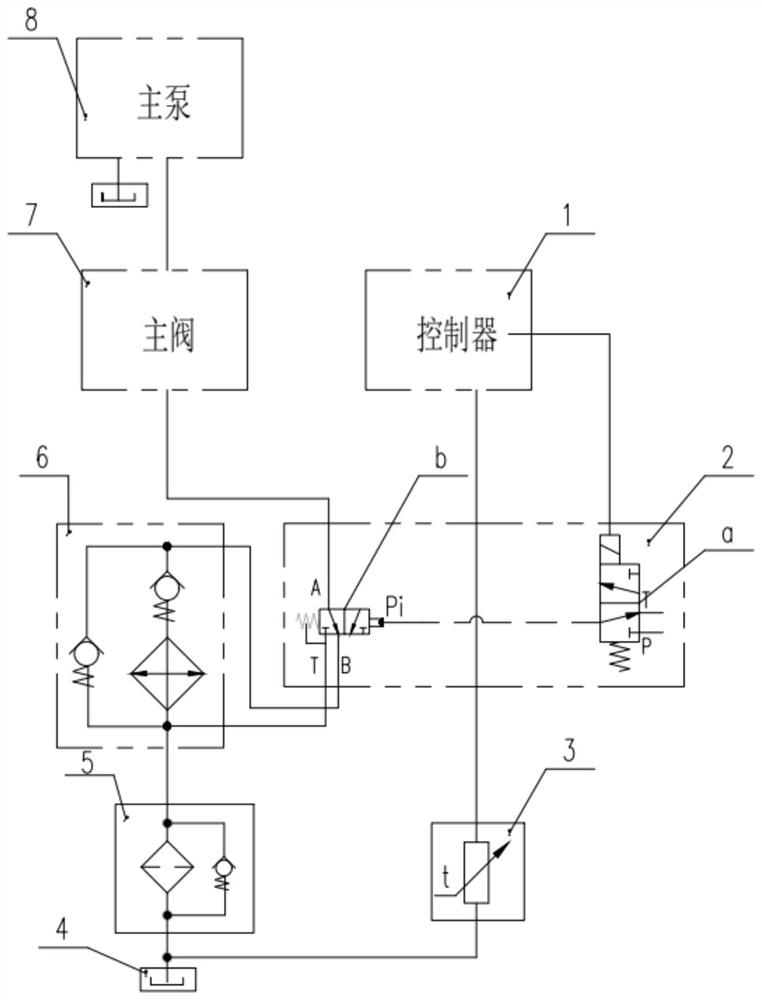

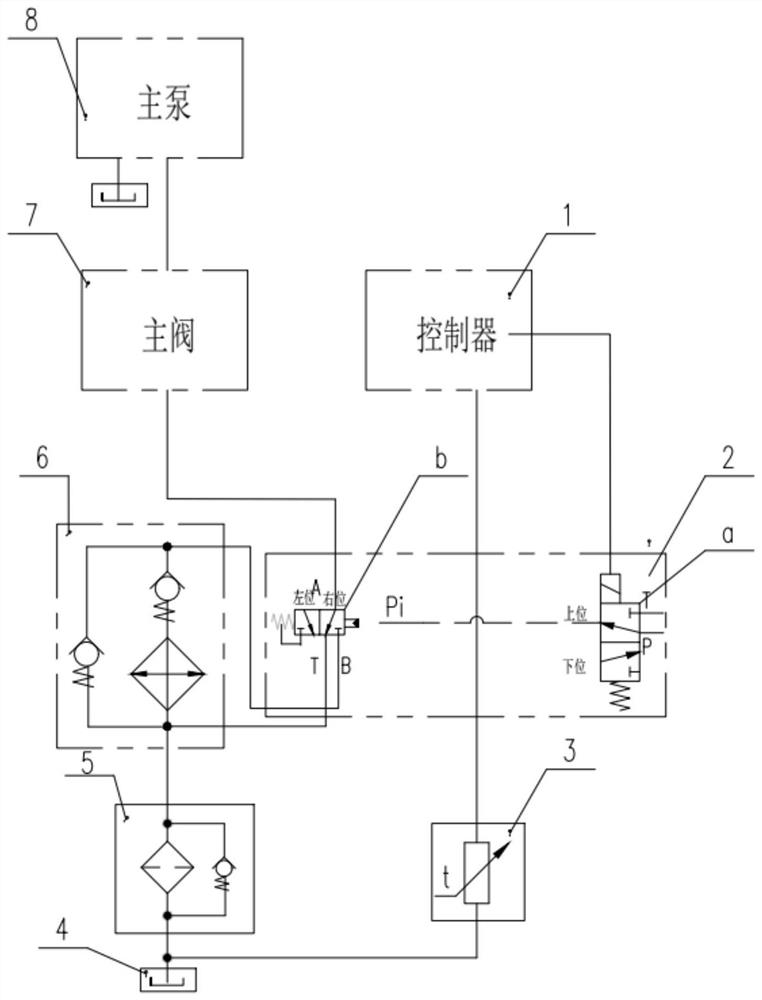

[0024] An excavator hydraulic oil heating system mainly includes: controller 1, electric hydrothermal replacement valve set 2, temperature sensor 3, hydraulic oil tank 4, filter 5, cooler 6, main valve 7, main pump 8, etc. .

[0025] The electrical fluid-controlled reversing valve set 2, a hydraulic oil tank 4, a filter 5, a cooler 6, a main valve 7, and a main pump 8 through a hydraulic line.

[0026] The electrical fluid-controlled reverse valve set 2, the temperature sensor 3 and the input port of the controller 1 are connected by the electrical harness.

[0027] The controller 1 receives the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com